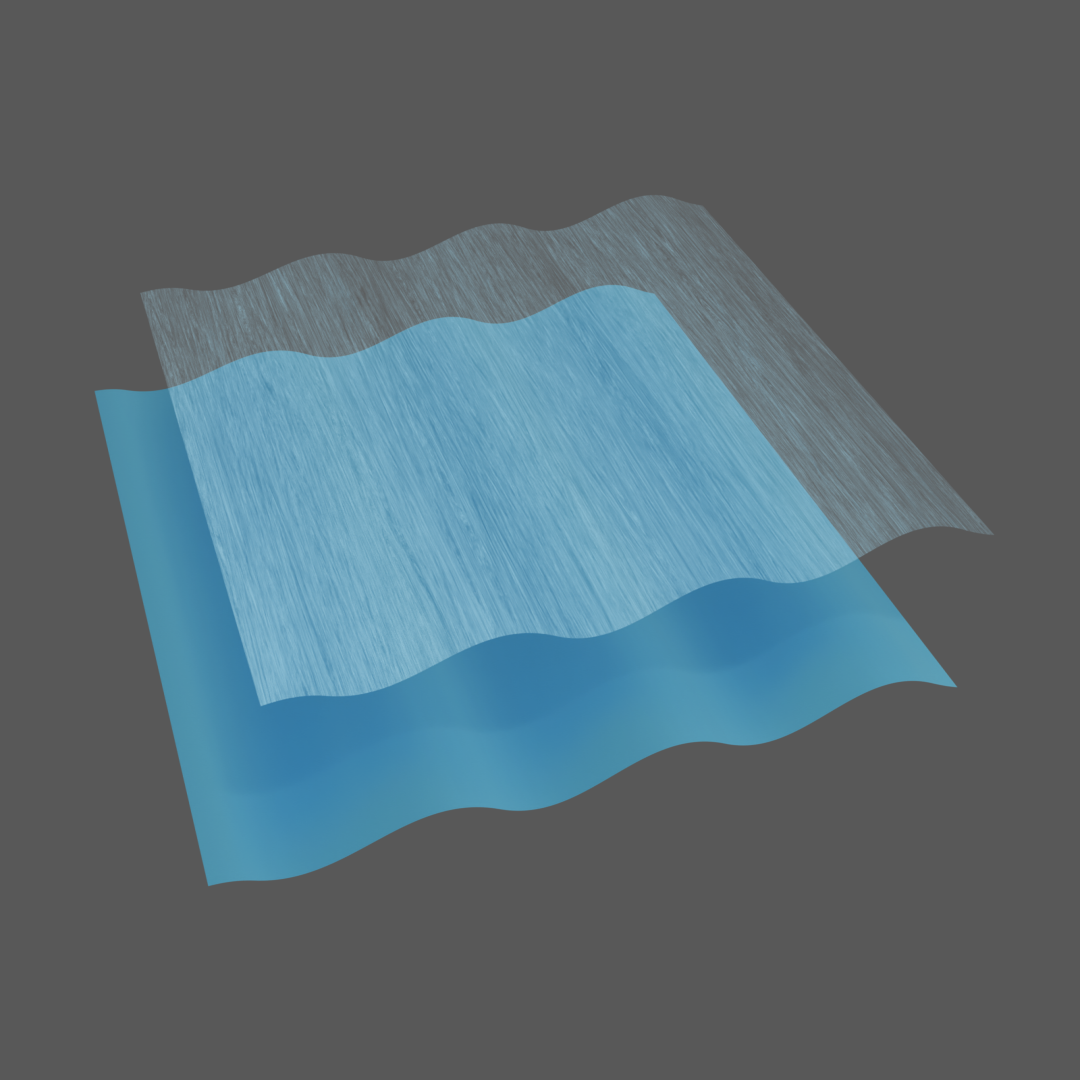

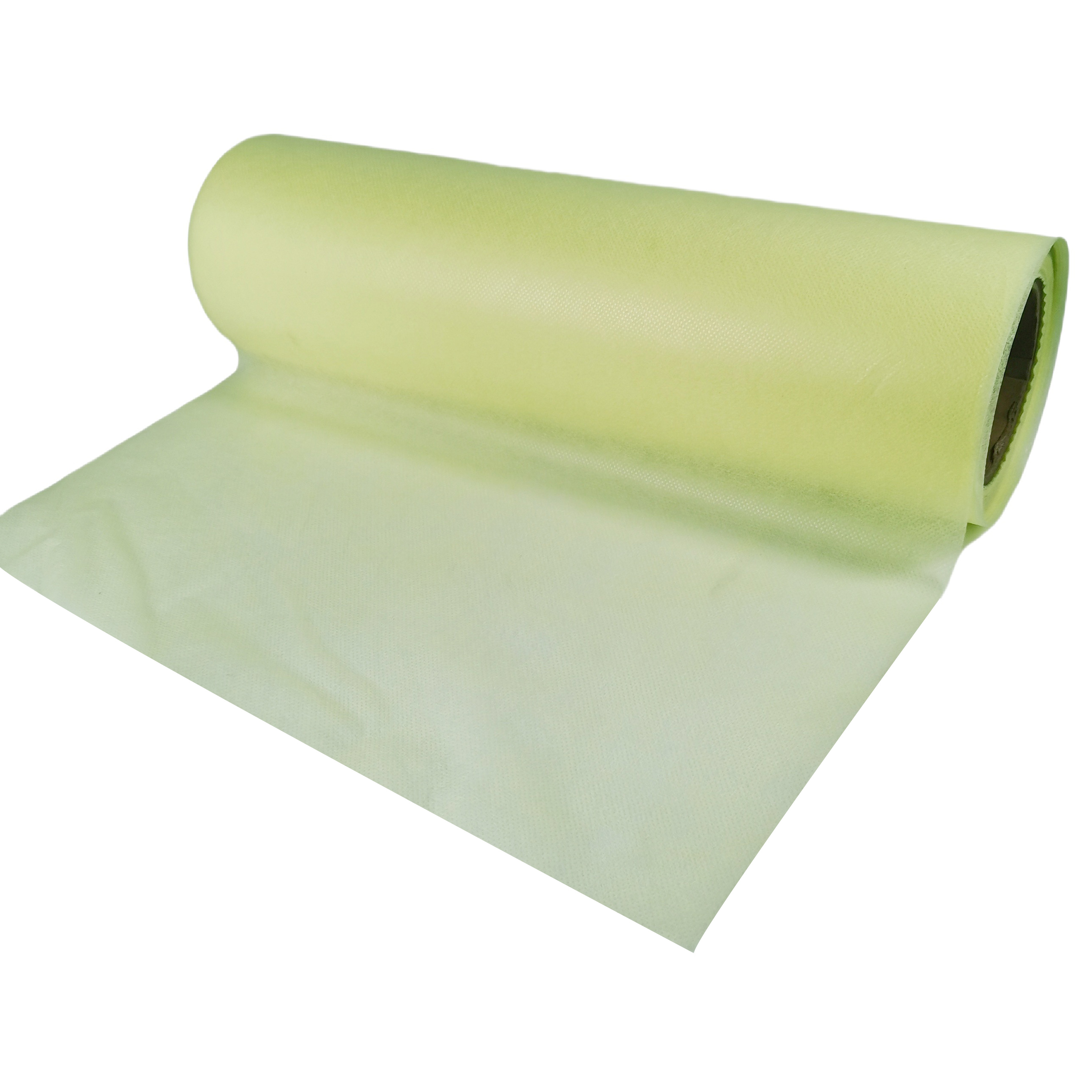

Wet-Laid Polyester Anti-Bacterial Nonwoven

Product Information

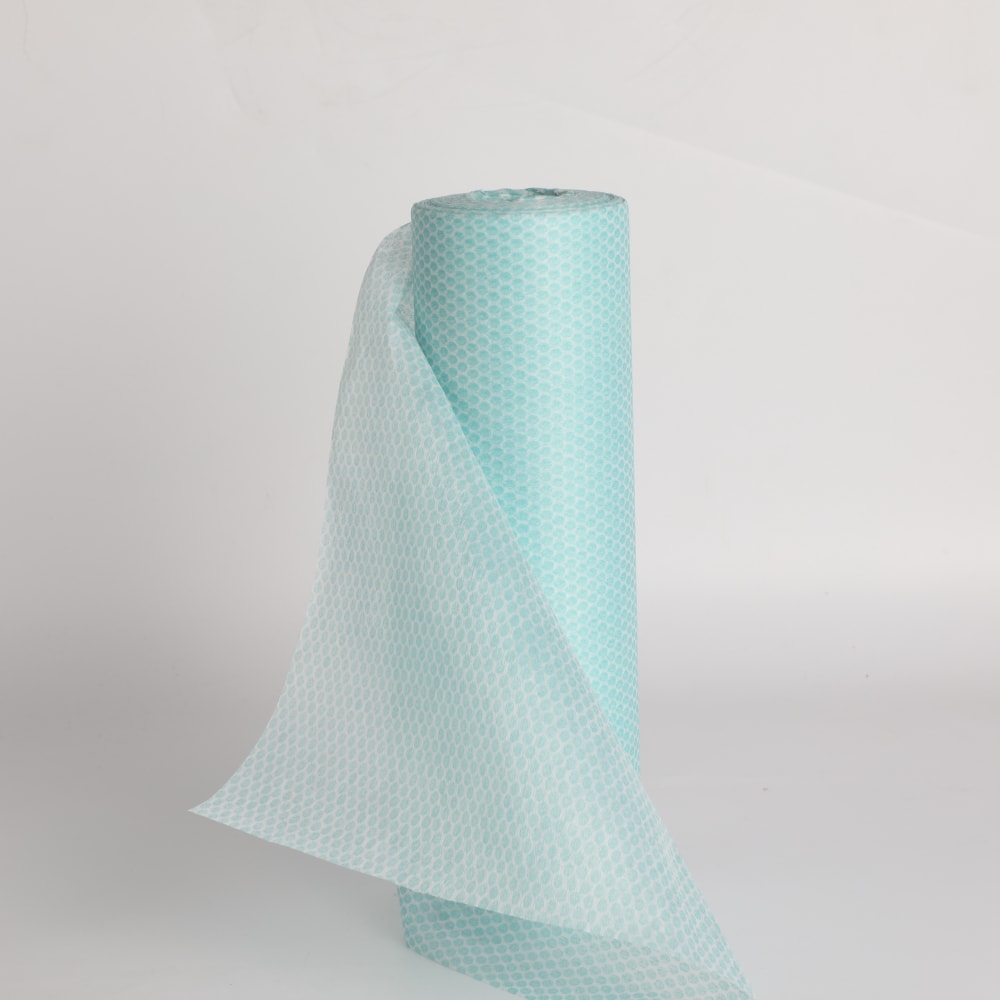

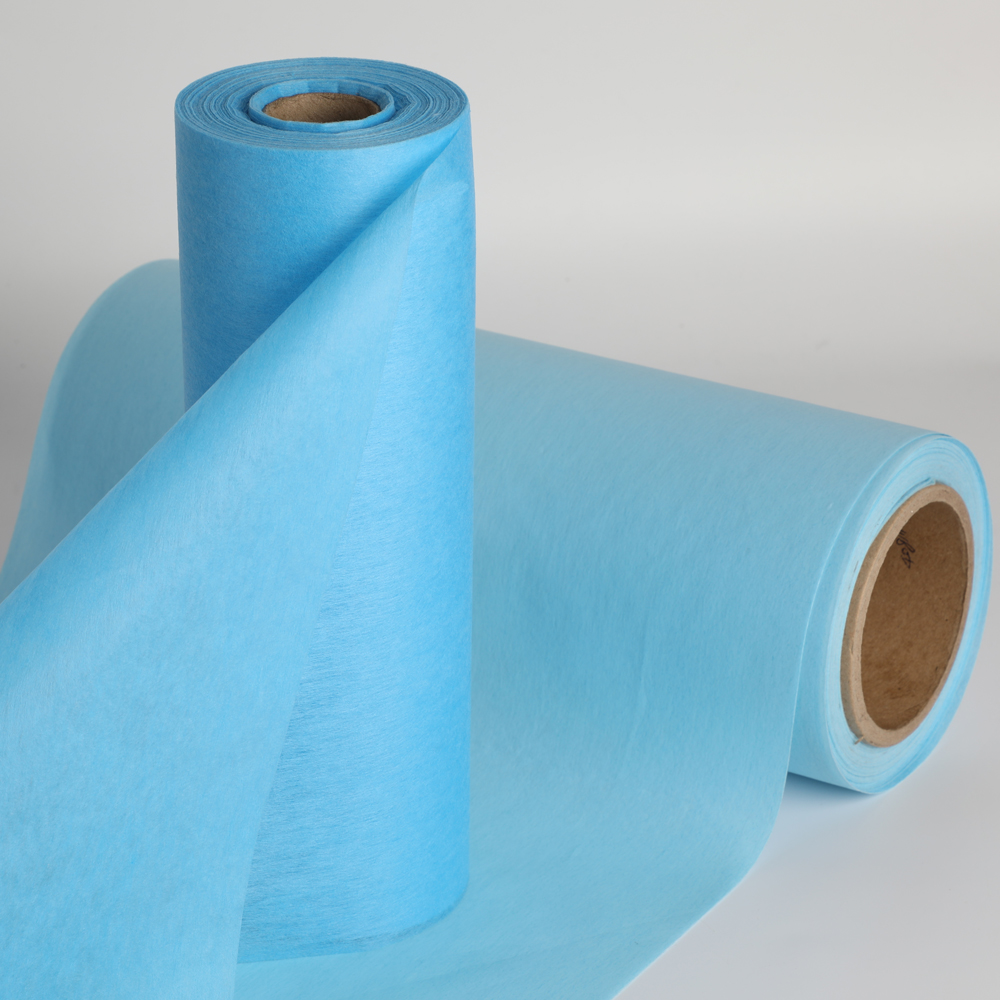

| Item | Anti-bacterial nonwoven |

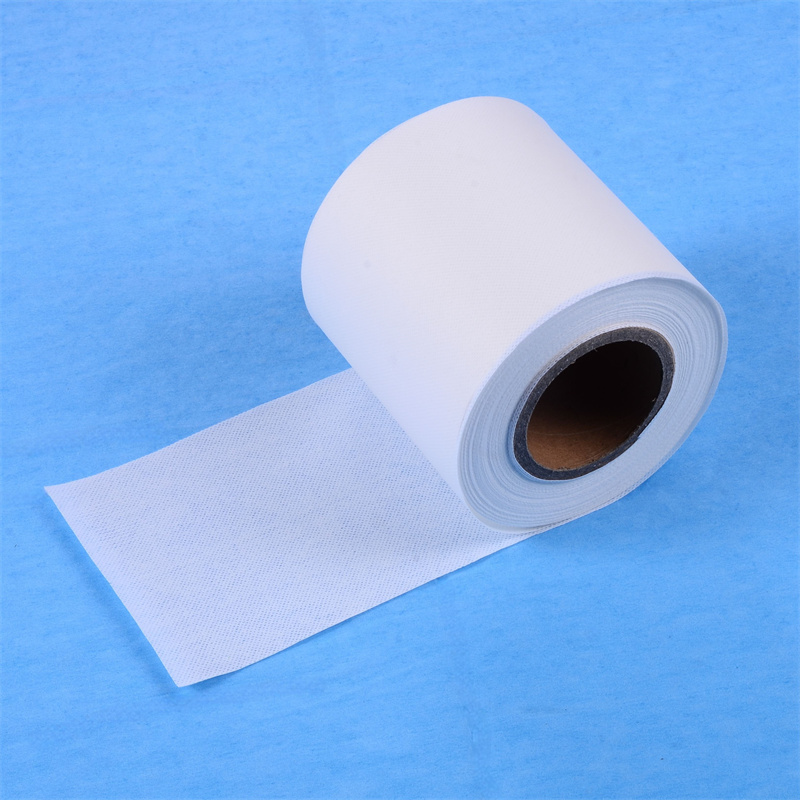

| Manufacturing Technology | Wet-laid |

| Width | Under 160 cm |

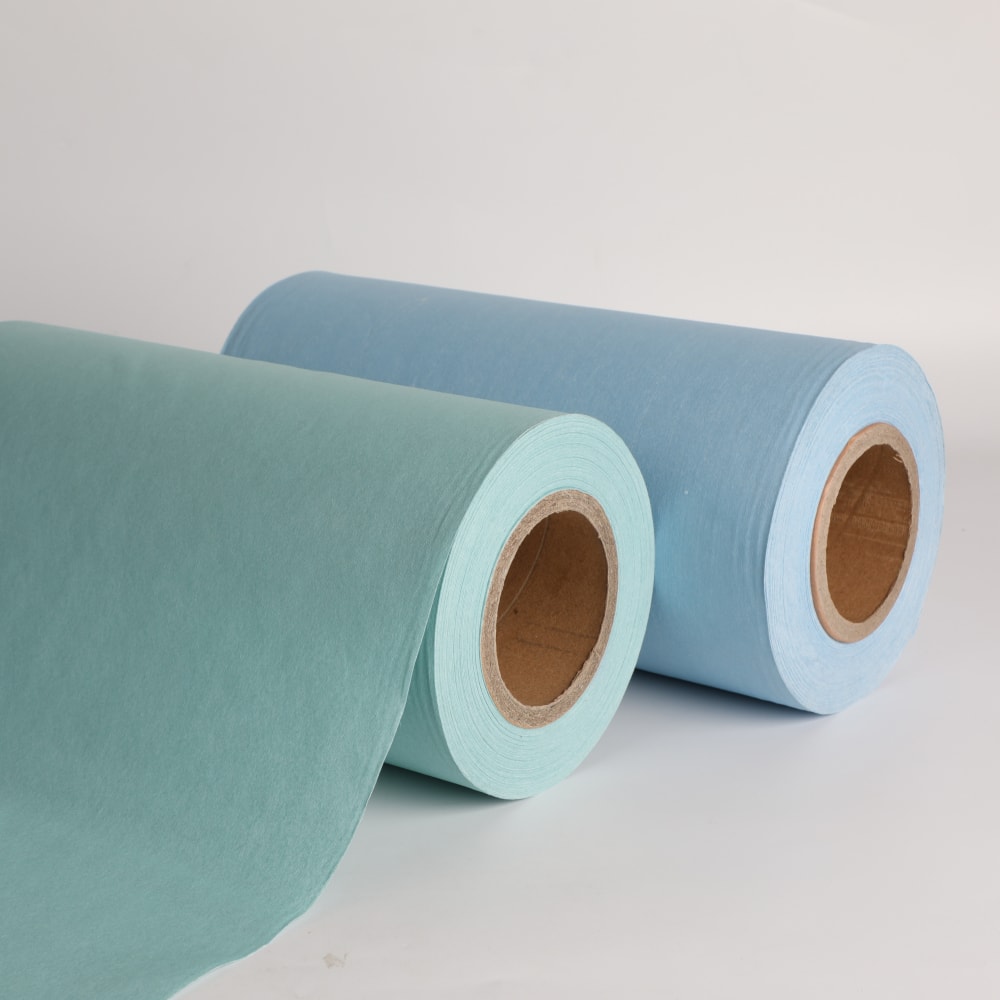

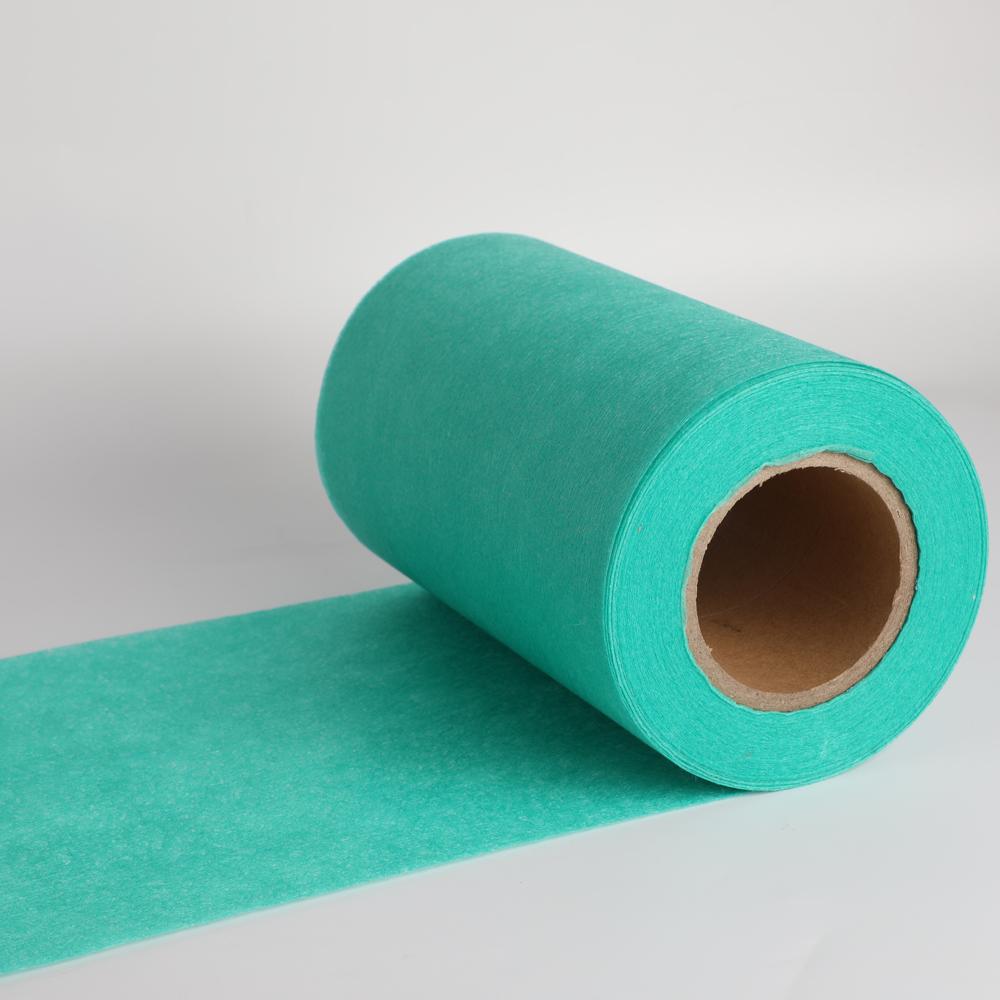

| Color(s) | Green,Purple,Blue |

| Weight | 50G ~ 80G |

| Material | Polyester |

| Shelf Life | 365 Days |

| Packing | PE wrapping |

Eco - friendly Material: Our antibacterial nonwoven fabric is crafted from environmentally friendly raw materials. In an era where environmental concerns are at the forefront, this feature ensures that our product not only performs excellently but also contributes to a sustainable future. It reduces the ecological footprint associated with traditional filtration materials, making it an ideal choice for environmentally conscious businesses.

Powerful Antibacterial Property: Equipped with advanced antibacterial technology, this nonwoven fabric effectively inhibits the growth of bacteria, molds, and other microorganisms. This not only ensures a cleaner and healthier filtration environment but also extends the service life of the filter media by preventing the degradation caused by microbial contamination.

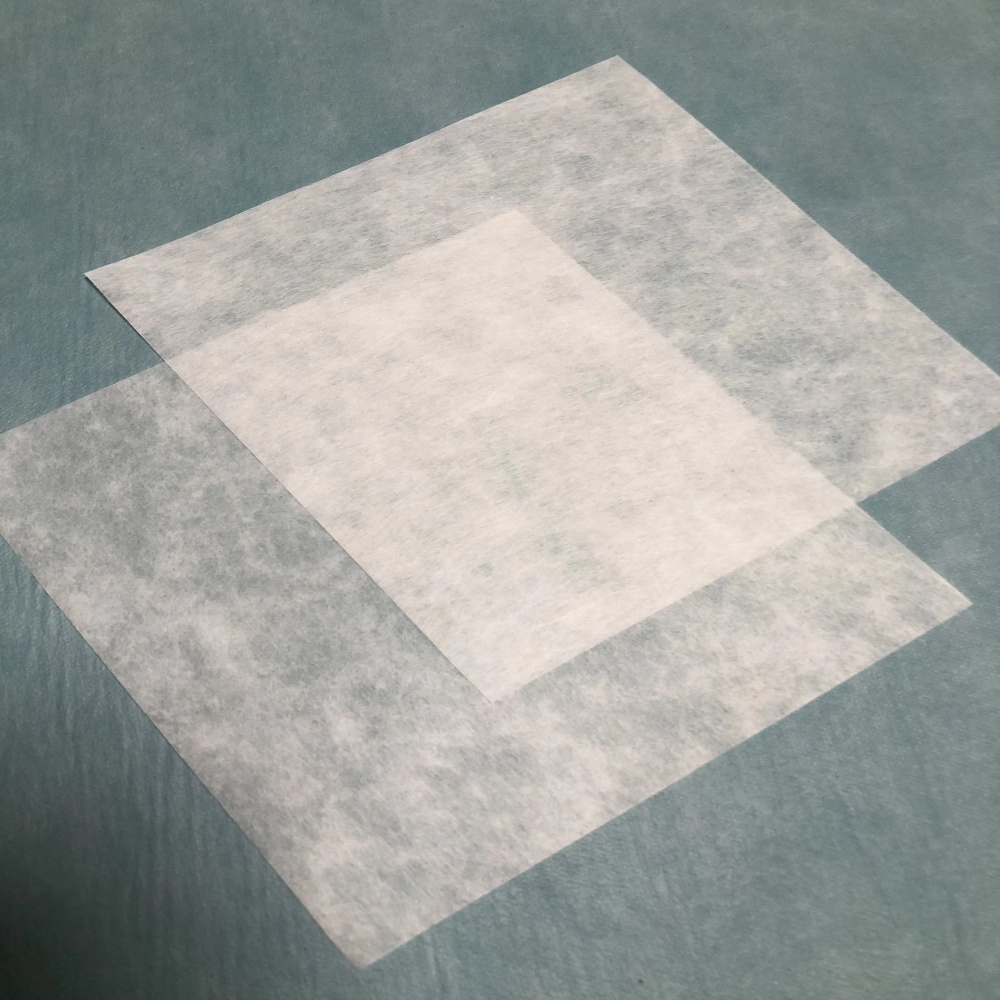

Superior Strength: Engineered with a unique wet - laid manufacturing technique, our nonwoven fabric boasts remarkable strength. It can withstand high - pressure airflows during the filtration process without tearing or deforming, ensuring consistent and reliable performance over an extended period.

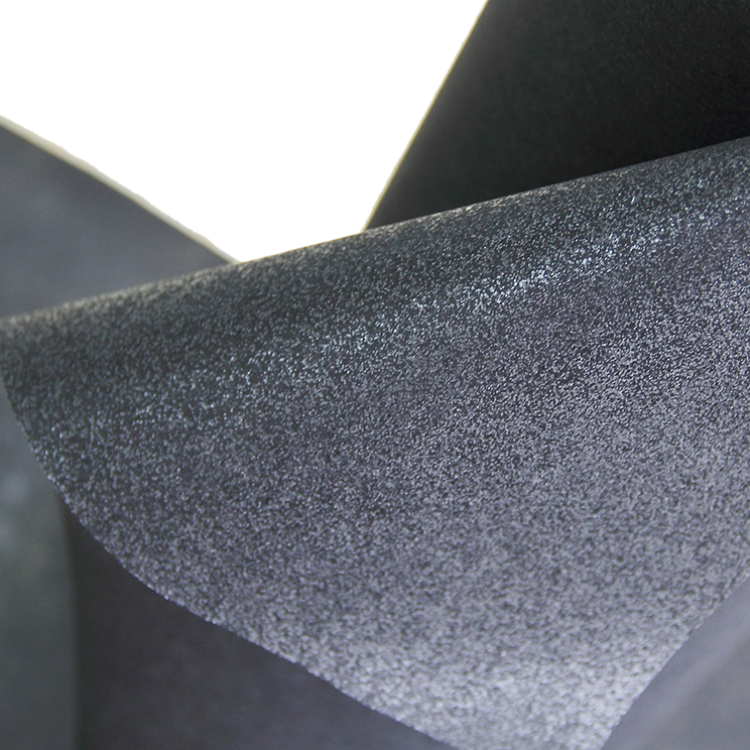

Product Details

Eco - friendly Composition

Our antibacterial nonwoven fabric is made from a carefully selected blend of sustainable polymers. These polymers are sourced from renewable or recycled materials, minimizing the consumption of virgin resources. For example, some of the raw materials are derived from post - consumer plastic waste that has been processed and transformed into high - quality nonwoven fibers. This not only reduces the amount of waste in landfills but also conserves energy compared to the production of traditional nonwoven fabrics made from entirely new materials. In the air filtration industry, where large quantities of filter media are used, the use of eco - friendly materials can have a significant cumulative positive impact on the environment.

Antibacterial Mechanism

The antibacterial property of our nonwoven fabric is achieved through the incorporation of specially designed antibacterial agents. These agents work in multiple ways. First, they have a strong affinity for the cell membranes of bacteria and other microorganisms. Once in contact, they disrupt the structure and function of the cell membranes, preventing the microorganisms from carrying out normal metabolic activities. Second, they can interfere with the genetic material of the microbes, inhibiting their reproduction. This dual - action mechanism ensures that the fabric can maintain a high level of antibacterial activity over time. In air filtration applications, this is crucial as it helps to prevent the growth of harmful bacteria and molds in the filter, which could otherwise be released back into the air, posing a health risk to users.

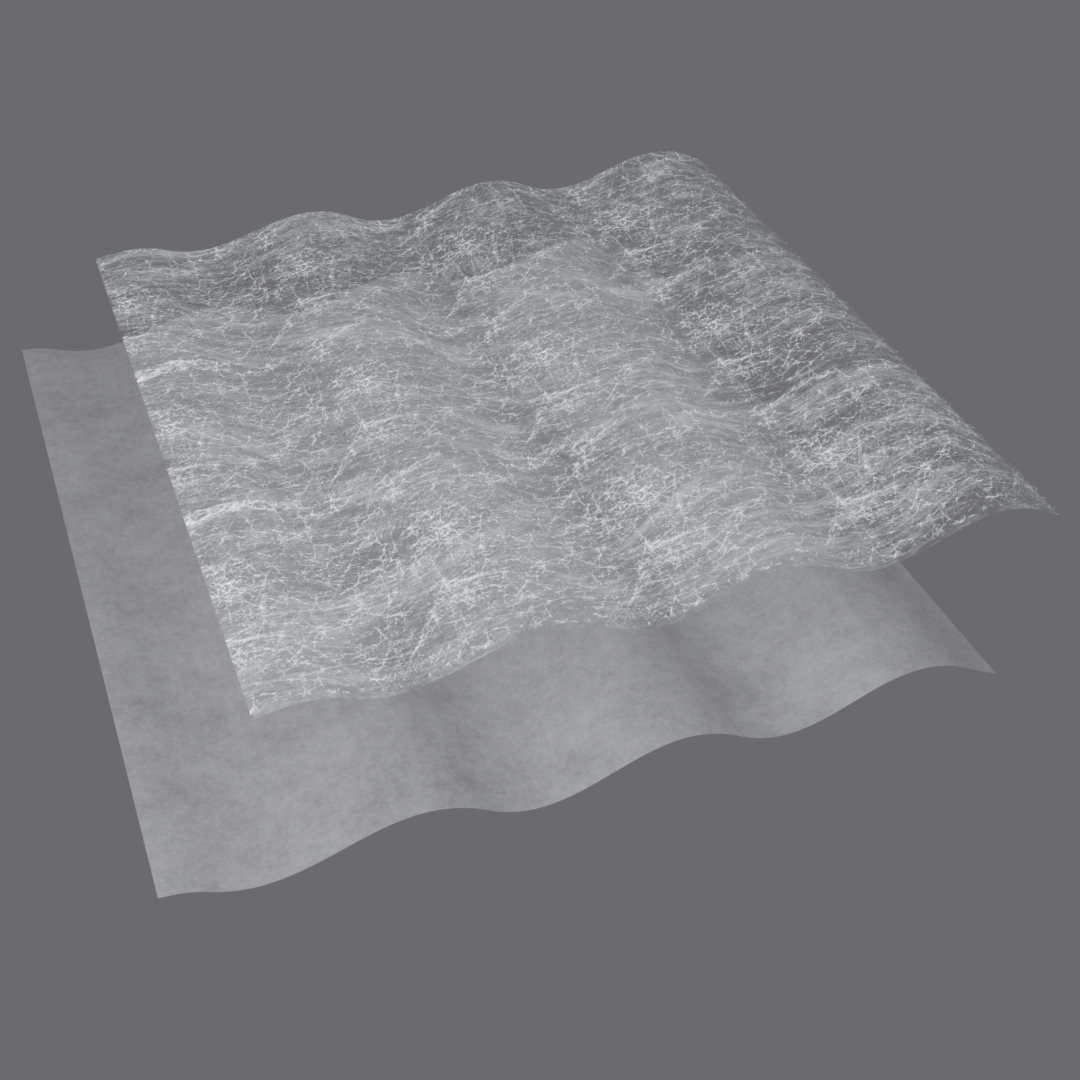

Strength and Durability

The wet - laid manufacturing method endows the nonwoven fabric with exceptional strength. During the wet - laid, the fibers are uniformly distributed and bonded together under precisely controlled conditions. This results in a more homogeneous and dense structure compared to dry - process nonwoven fabrics. The strong inter - fiber bonds enable the fabric to resist the mechanical stresses imposed by high - velocity airflows in air filtration systems. Whether it is in a residential air purifier or a large - scale industrial air - handling unit, our nonwoven fabric can maintain its integrity and filtration efficiency, reducing the frequency of filter replacements and thus saving costs for our customers.

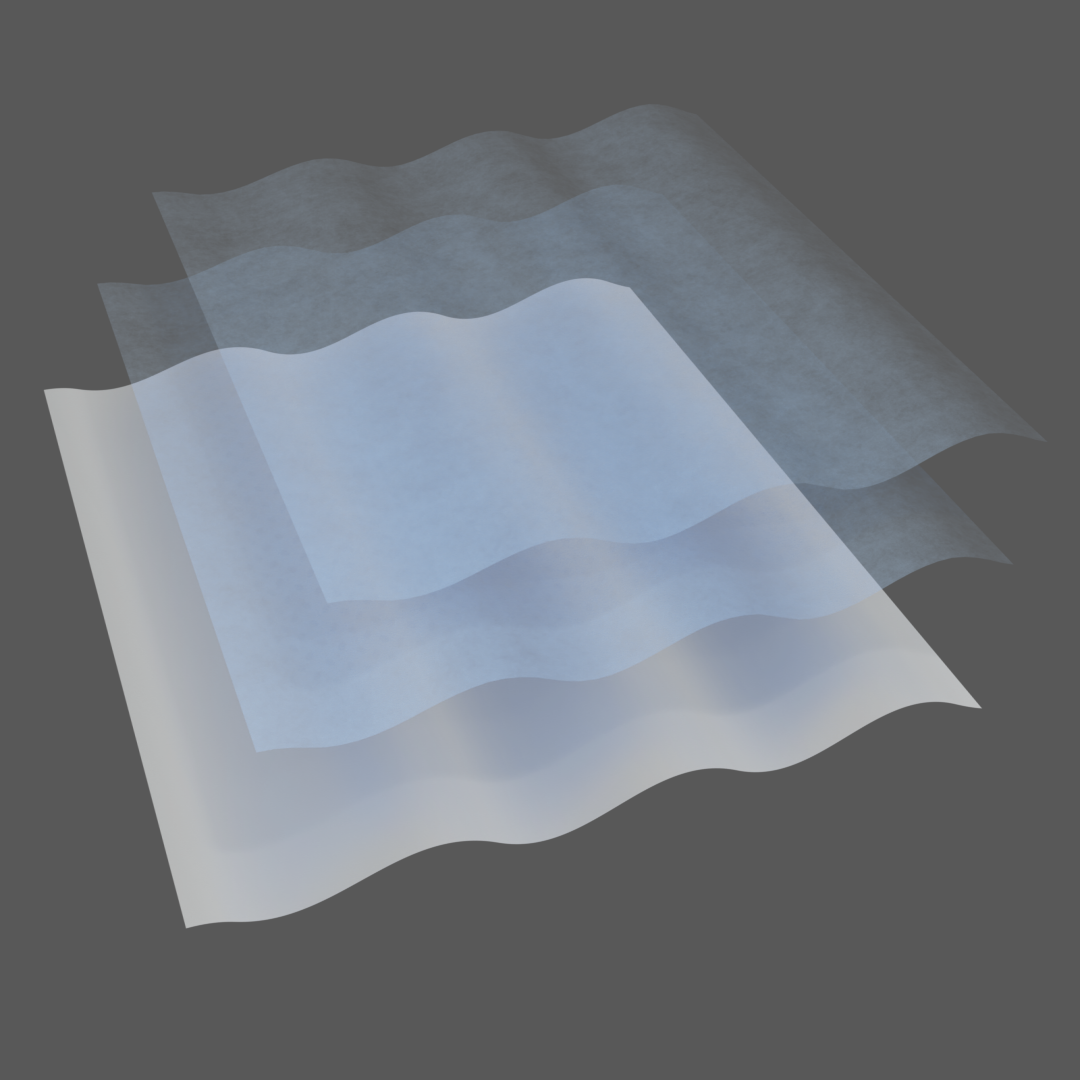

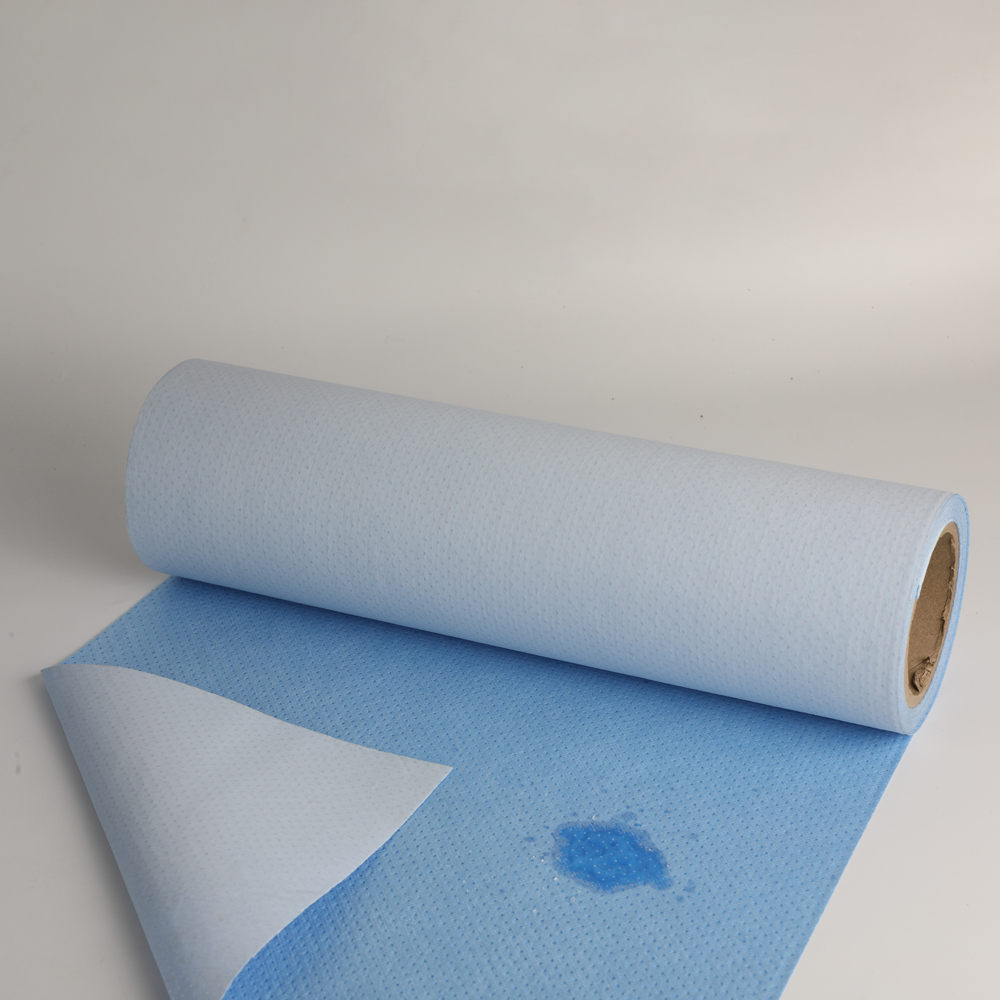

Multi Laminates

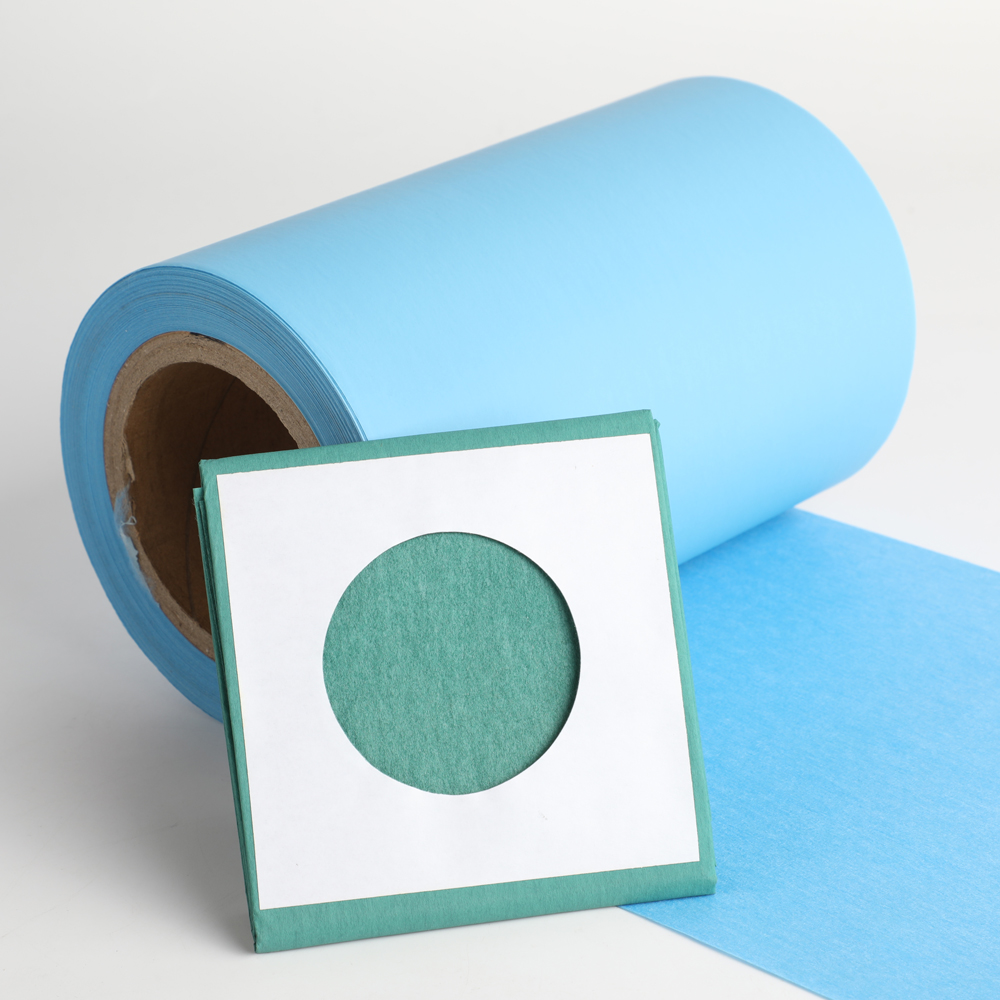

Multi Laminates Spunlace Nonwoven Laminates

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

Air Filter Media Liquid Filter Media

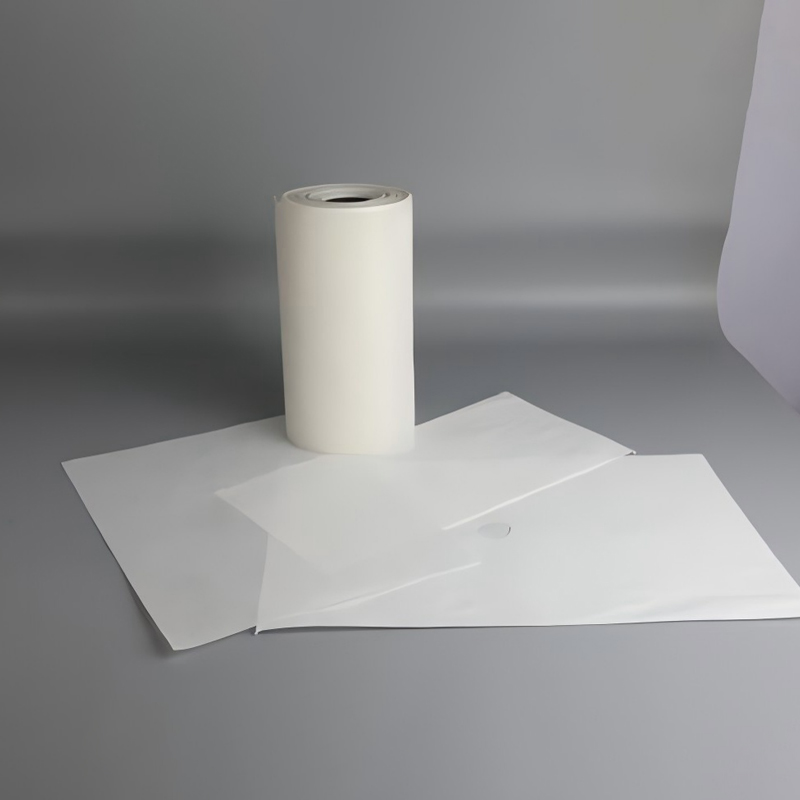

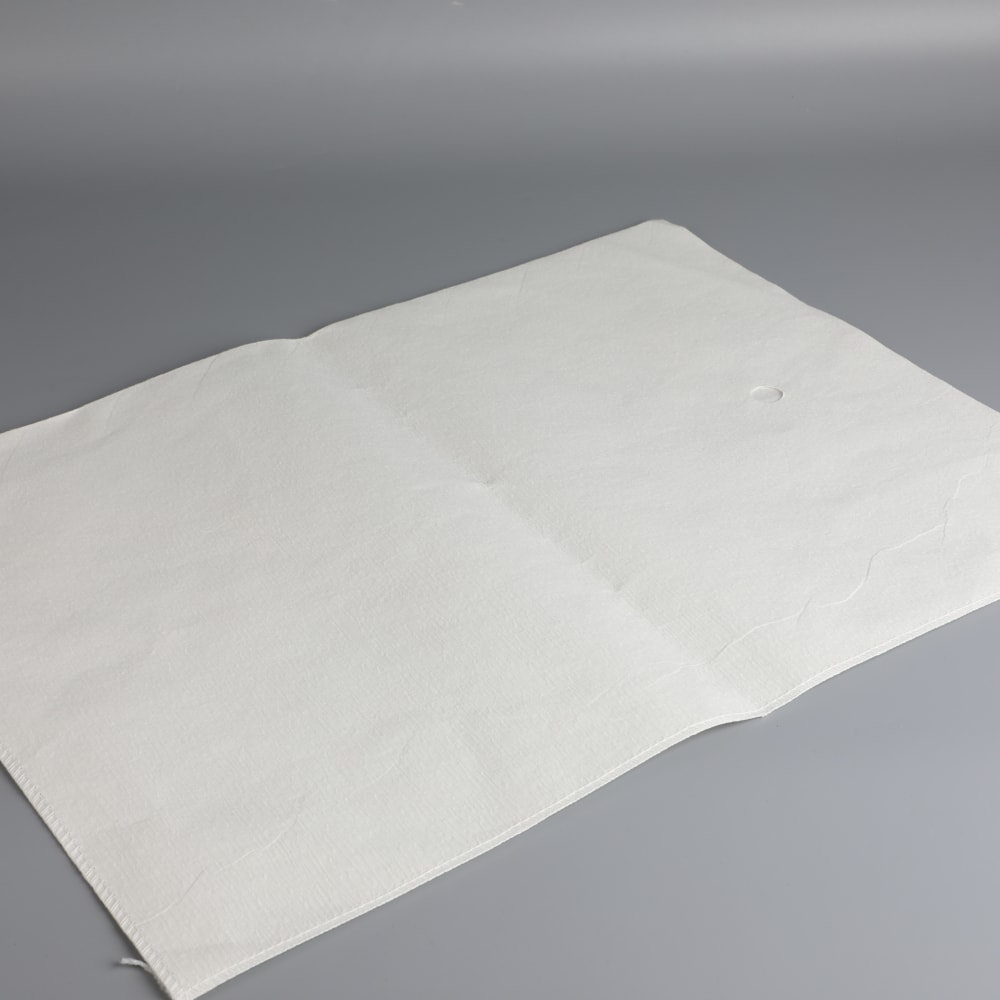

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

Breathable Film Laminates Nonwoven Interlining

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven