What are the differences between non-woven fabric and woven fabric?

nonwoven fabrics are fundamentally different from traditional textiles in terms of manufacturing processes, structural characteristics and functional applications. Unlike traditional textiles that require yarn spinning and interweaving, nonwoven fabrics are produced by directly bonding or winding fibers (for example, through water entanglement, meltblown or needling), thereby forming a random three-dimensional fiber structure. This unique structure endows nonwoven fabrics with superior porosity (typically 70-90%, while textiles have 20-50%), directional uniformity of strength, and customizable permeability, thereby enabling special functions such as liquid filtration or bacterial barriers.

The production efficiency of non-woven fabric is significantly better than that of woven fabric. Through modern production lines, non-woven fabric saves 35% more energy than textile fabric and also reduces material waste by 25%. The cost advantage of nonwoven fabrics also exists in disposable applications. For instance, the unit price of nonwoven fabrics used in medical masks or wet wipes is 40% lower. In terms of functionality, non-woven fabrics outperform textiles in specific fields: the meltblown layer can capture 99.5% of air particles; SMS composite materials combine the waterproofing and breathability of surgical gowns. However, traditional textiles still dominate in applications such as clothing where durability is a priority due to their higher wear resistance and drape.

Of course, due to the different sources of raw materials, the impact on the environment may also vary. Whether it is textile fabric or nonwoven fabric, plant-based nonwoven fabric (viscose,woodpulp, lyocell) can be biodegraded within a few weeks, while petroleum-derived versions persist like synthetic fibers.

Multi Laminates

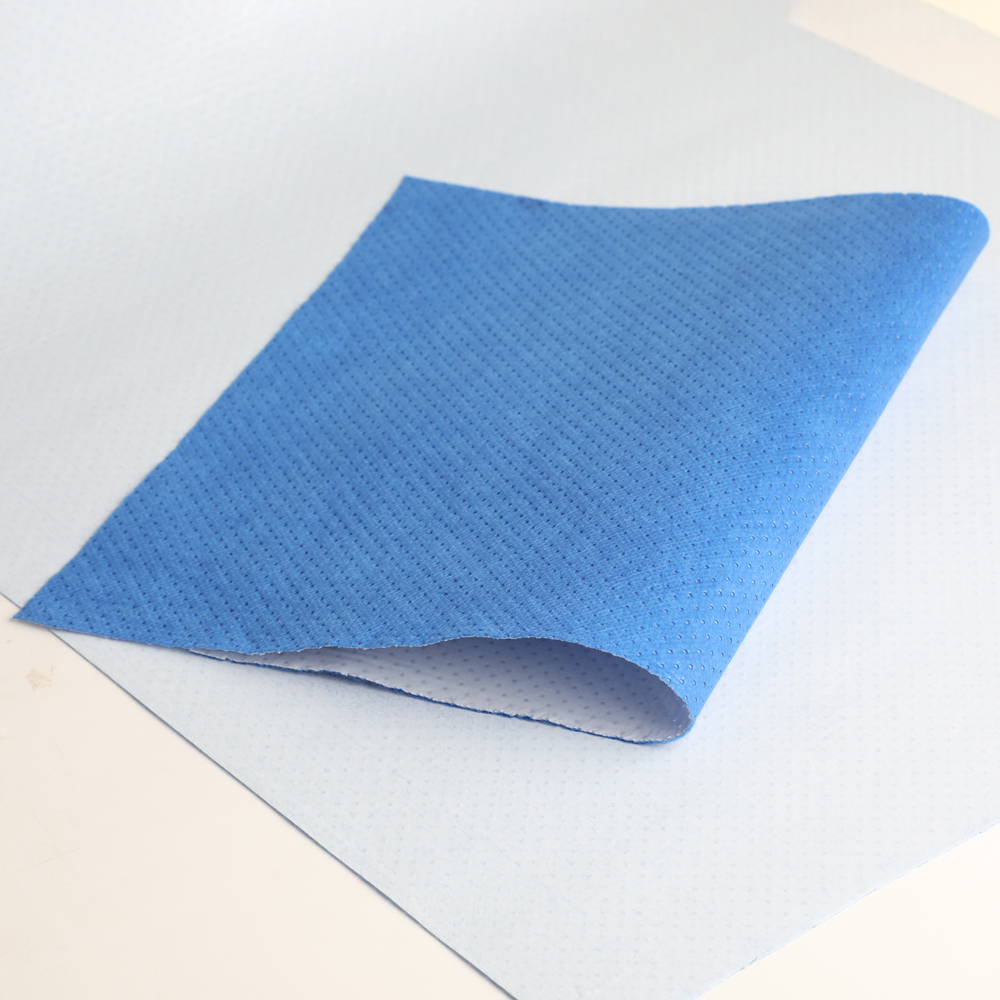

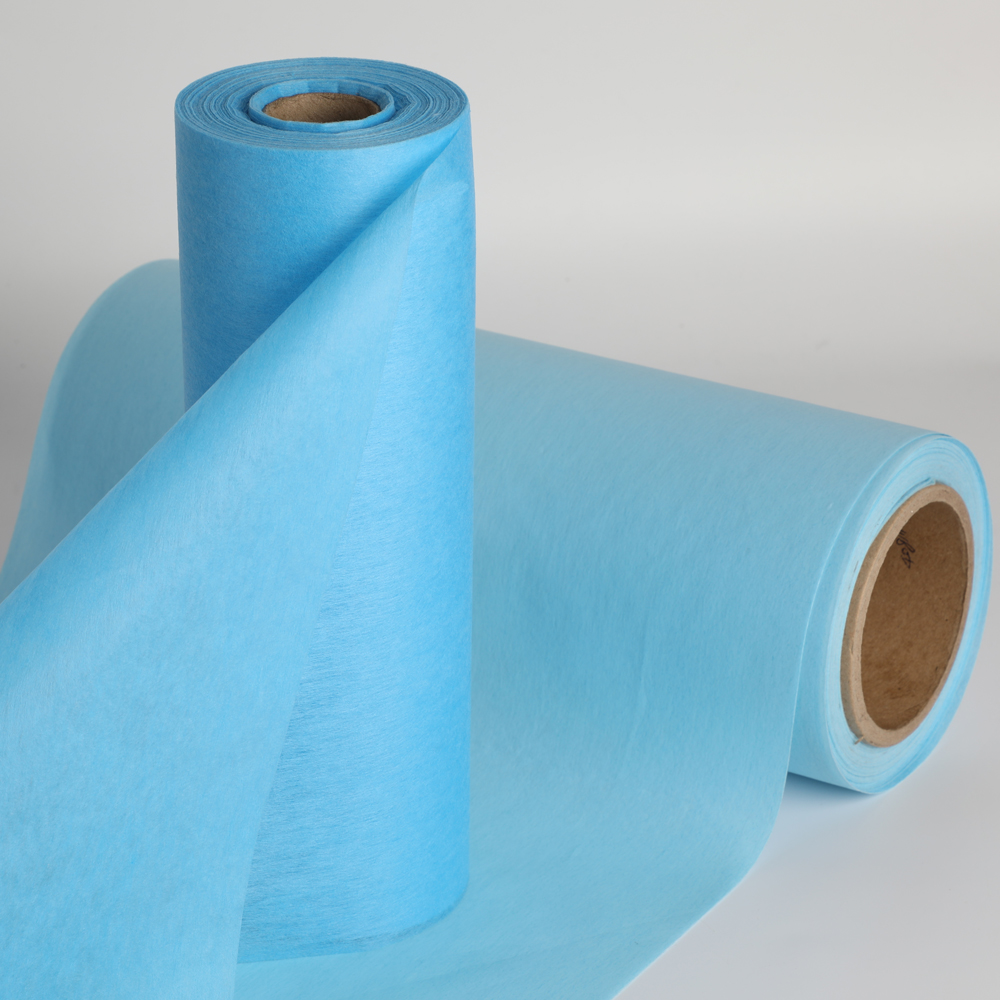

Multi Laminates Spunlace Nonwoven Laminates

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

Air Filter Media Liquid Filter Media

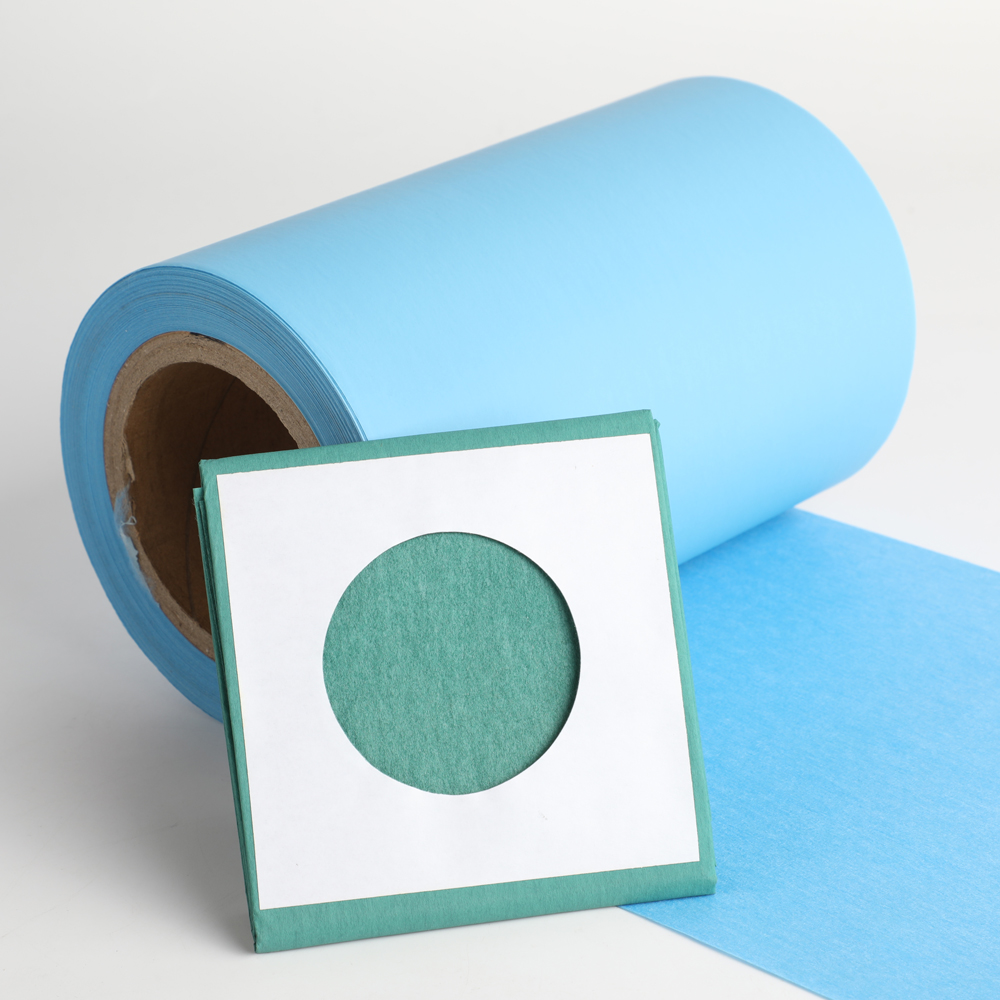

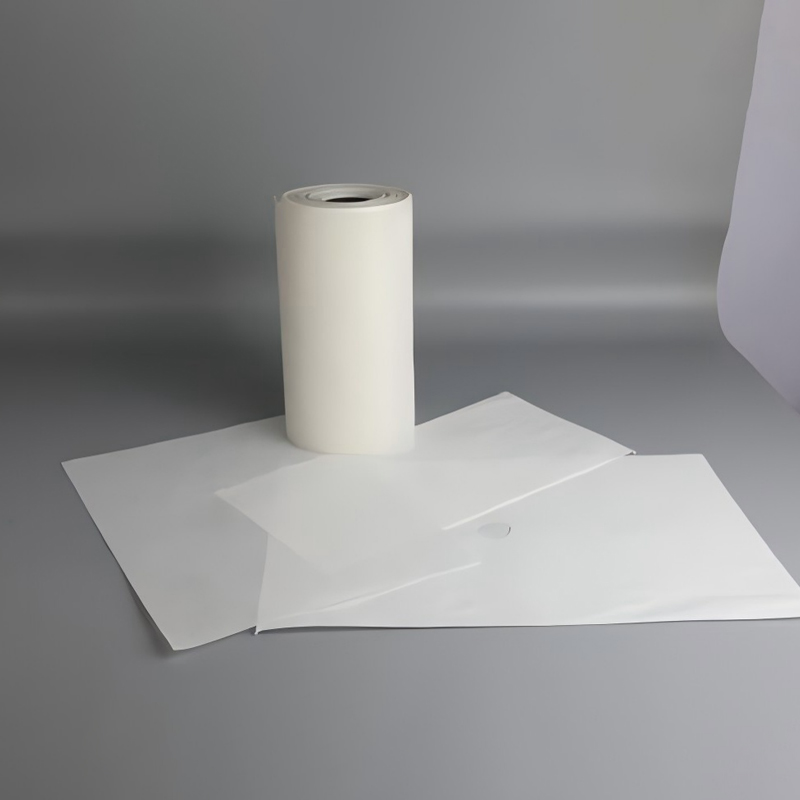

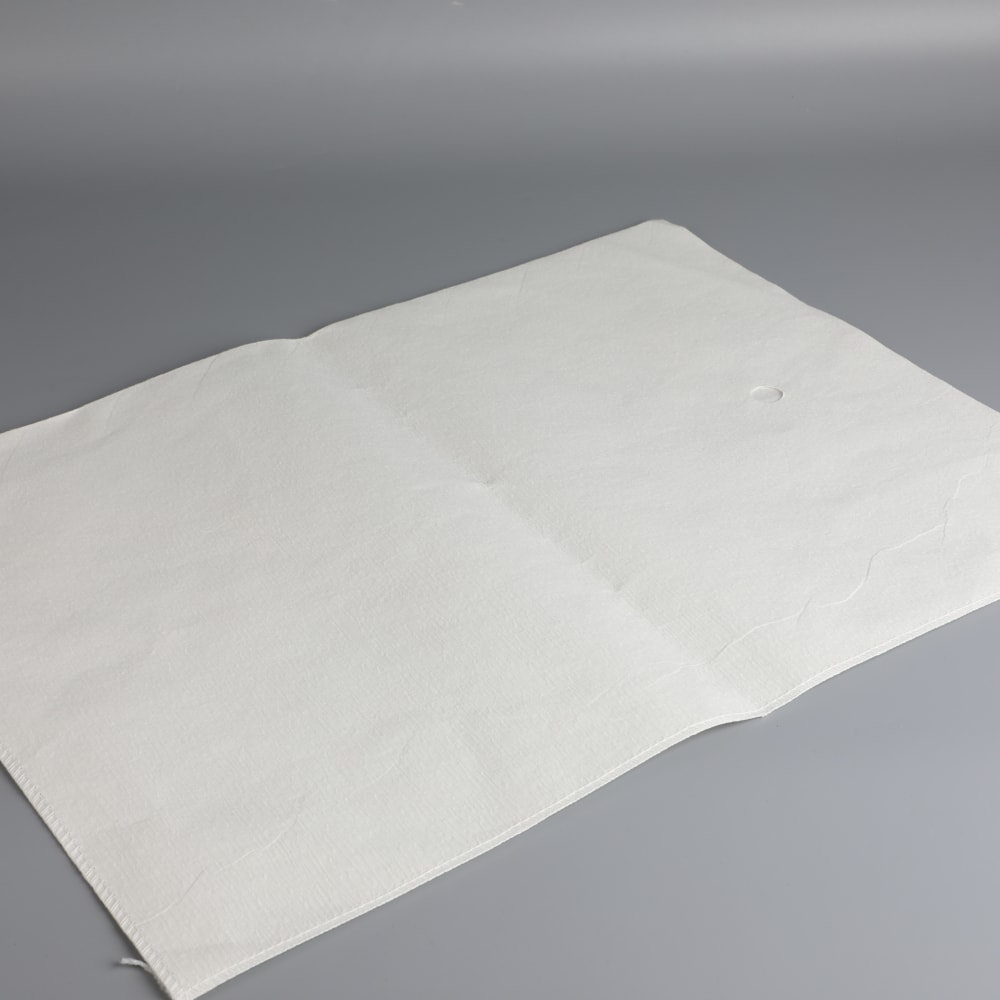

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

Breathable Film Laminates Nonwoven Interlining

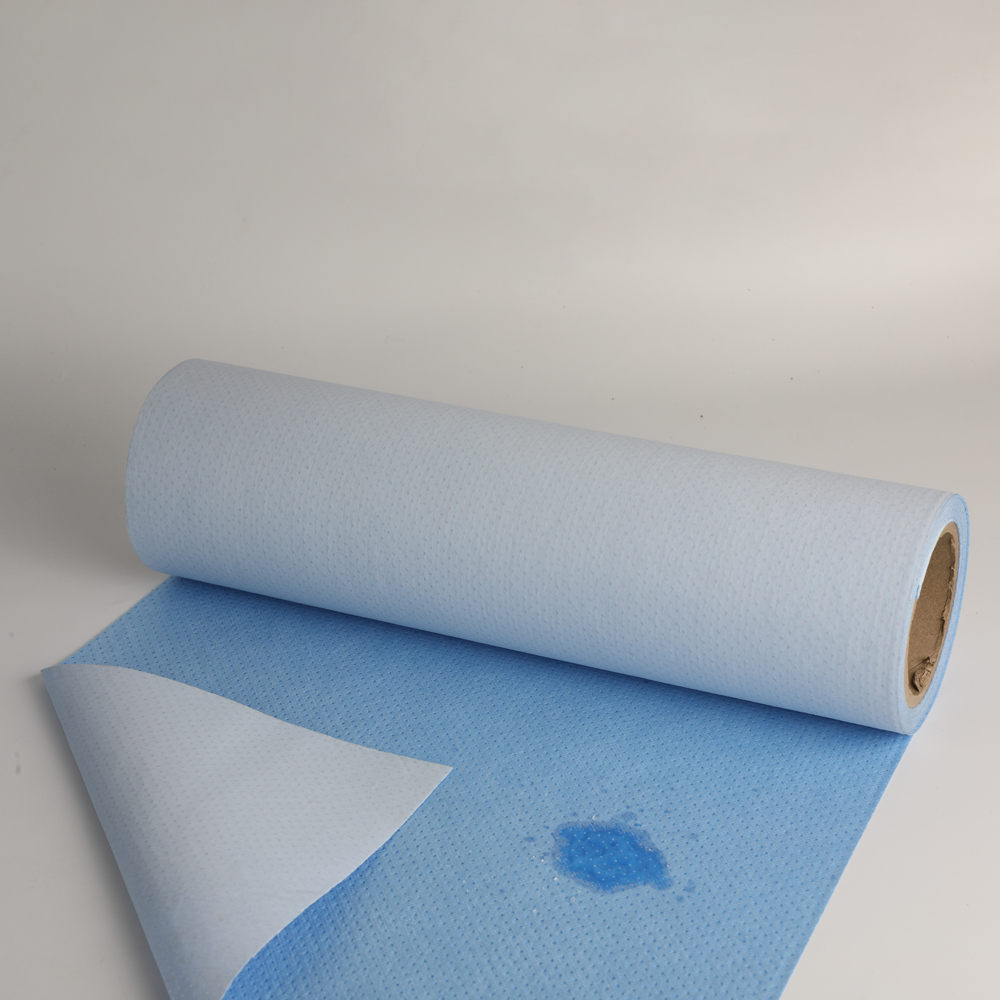

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

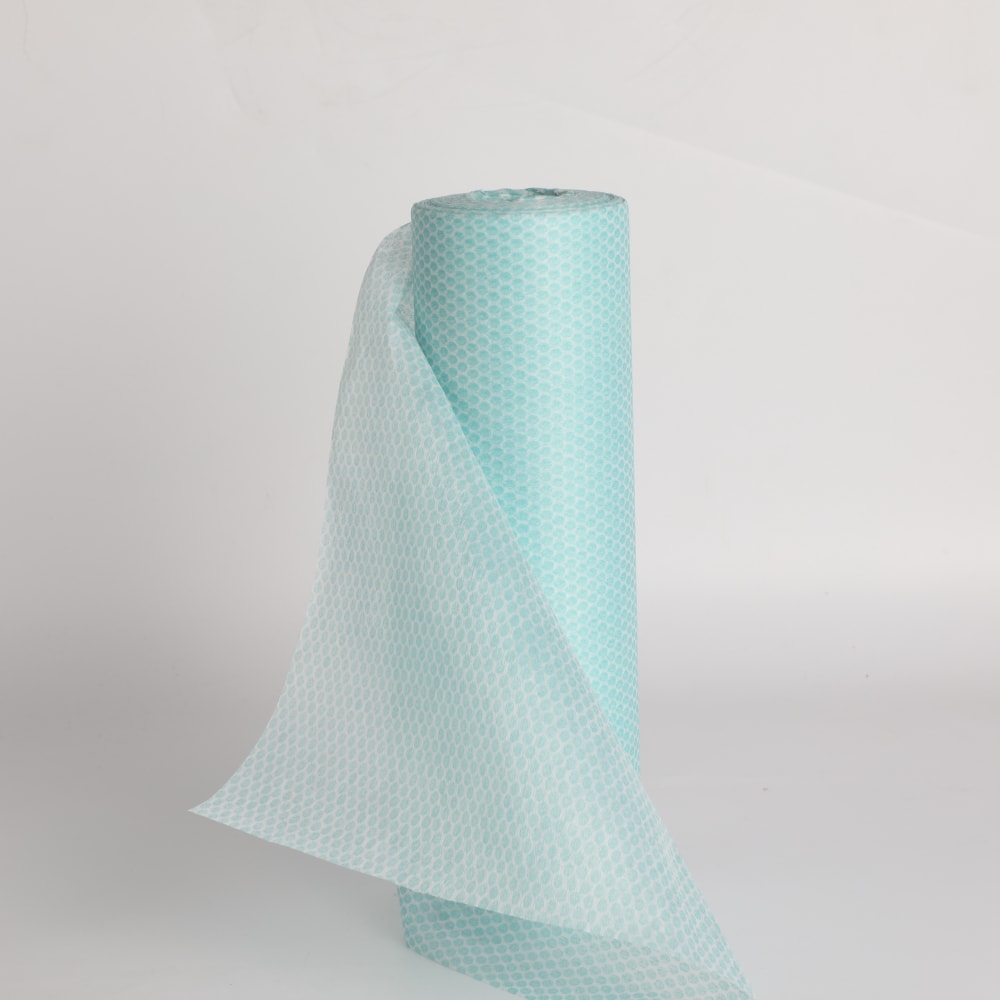

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven