Fusible Nonwoven Interlining Redefines the Modern Apparel Manufacturing

Market Demanding

The demand for interlinings in the global Nonwoven Materials market has soared.In this case, non woven fusible interlining—key components for reinforcing collars, cuffs, and belts—is undergoing a technological breakthrough in powder adhesive application.

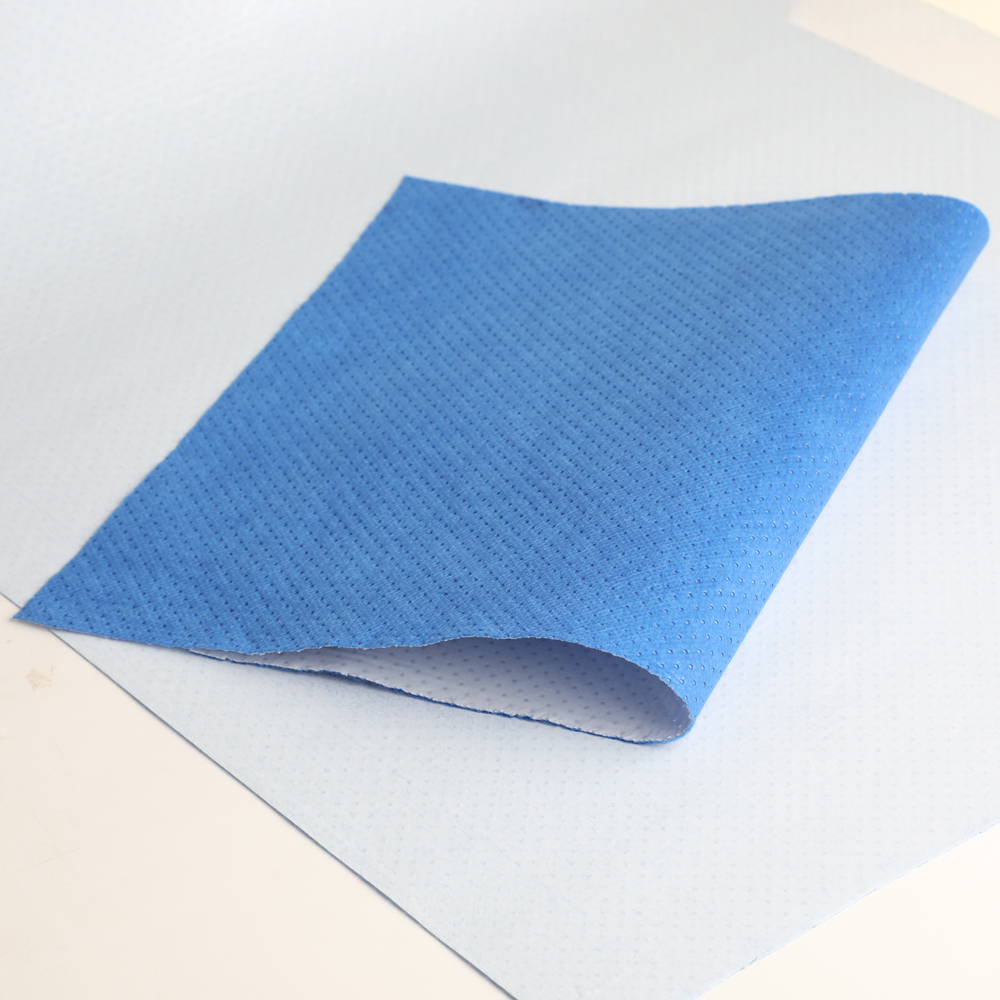

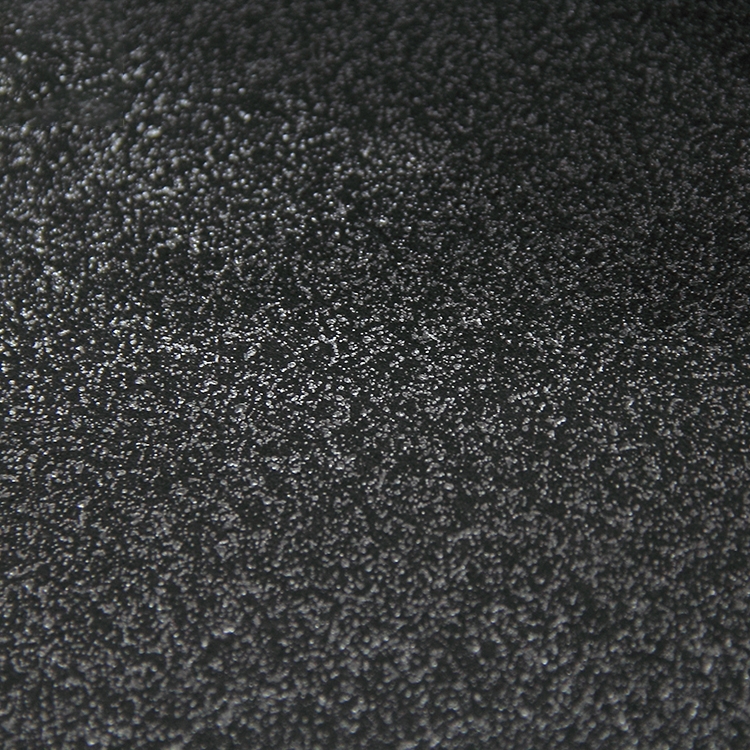

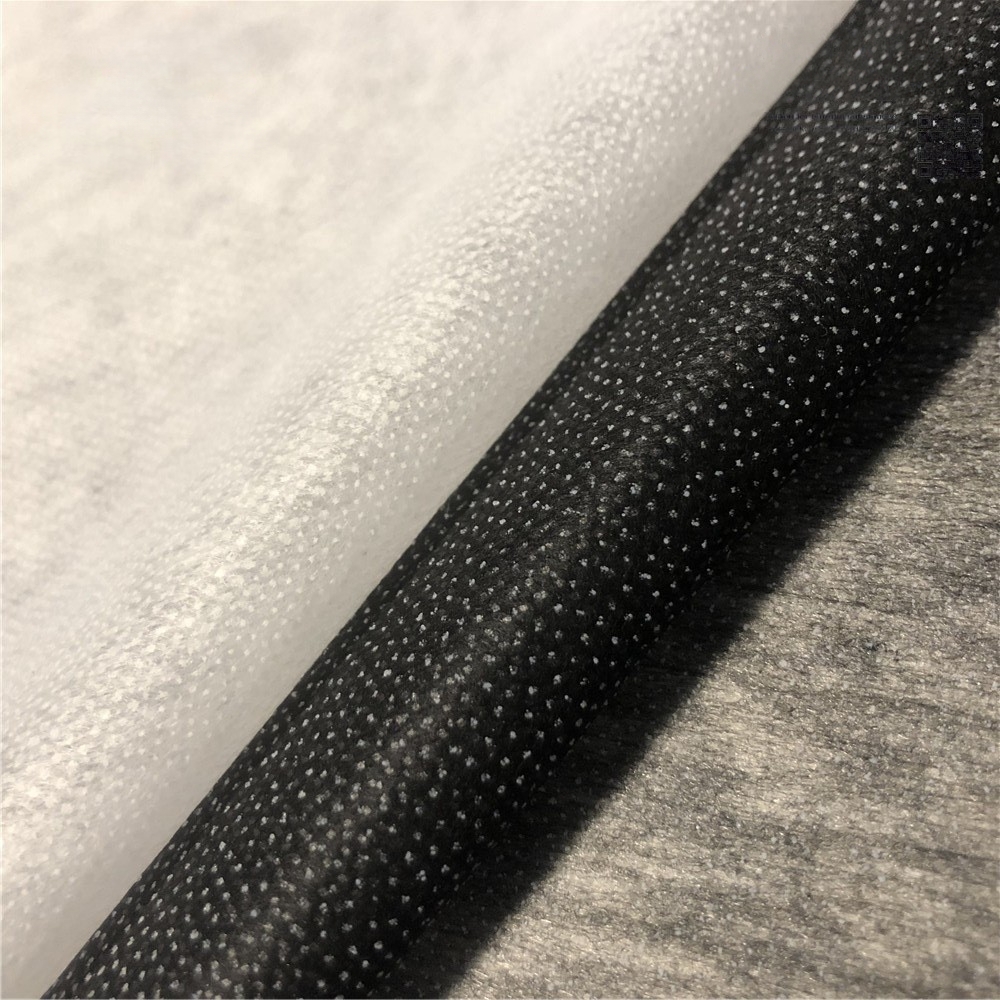

Technological breakthrough: Precision meets the requirements of sustainable hybrid double-point coating technology Our new type of adhesive interlining fabric adopts advanced powder coating technology, which can solve the problems of glue leakage, stiffness and poor wash resistance that often occur in traditional interlining fabrics. Despite its excellent performance, it can still remain thin, light and breathable.

Conclusion: A Quiet Revolution in Apparel Industry

Non woven fusible interfacing is evolving to a multi-functional driver of durability, sustainability, and design freedom, proving that even the "hidden" elements of fashion can drive industry transformation.

Multi Laminates

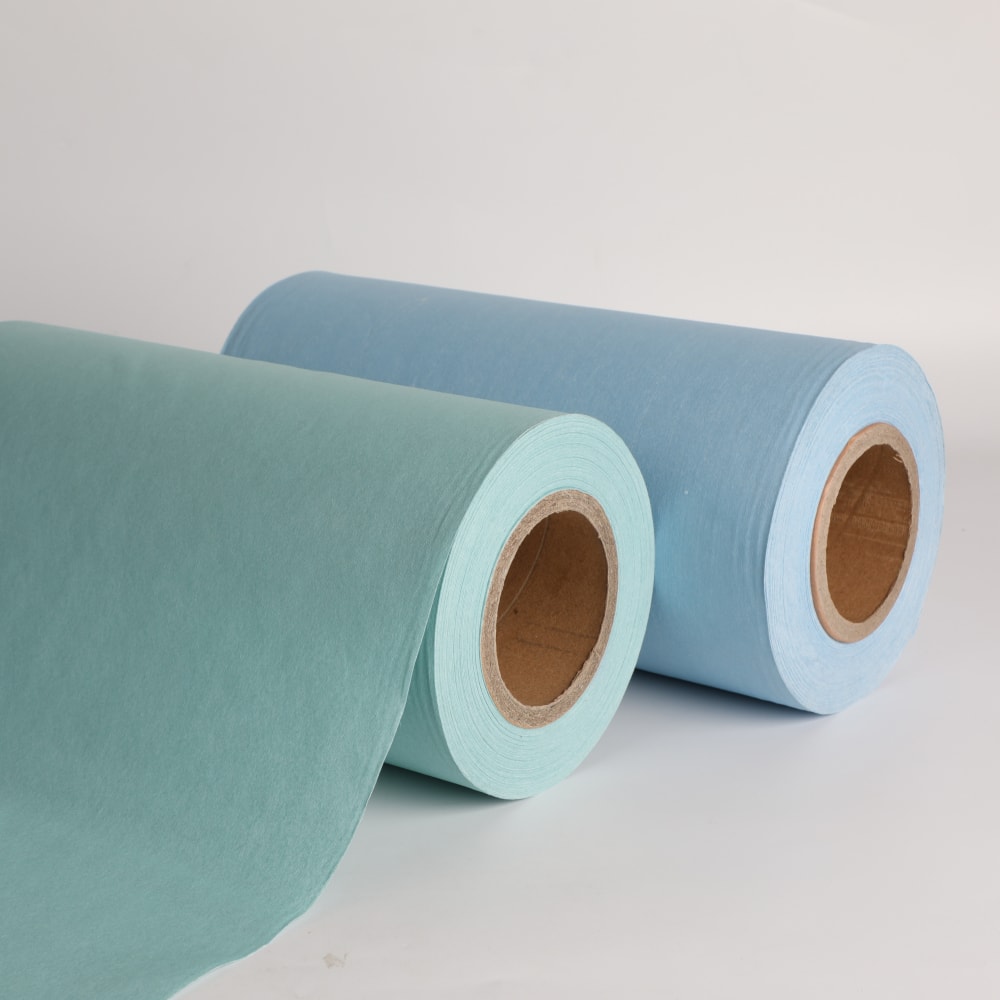

Multi Laminates Spunlace Nonwoven Laminates

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

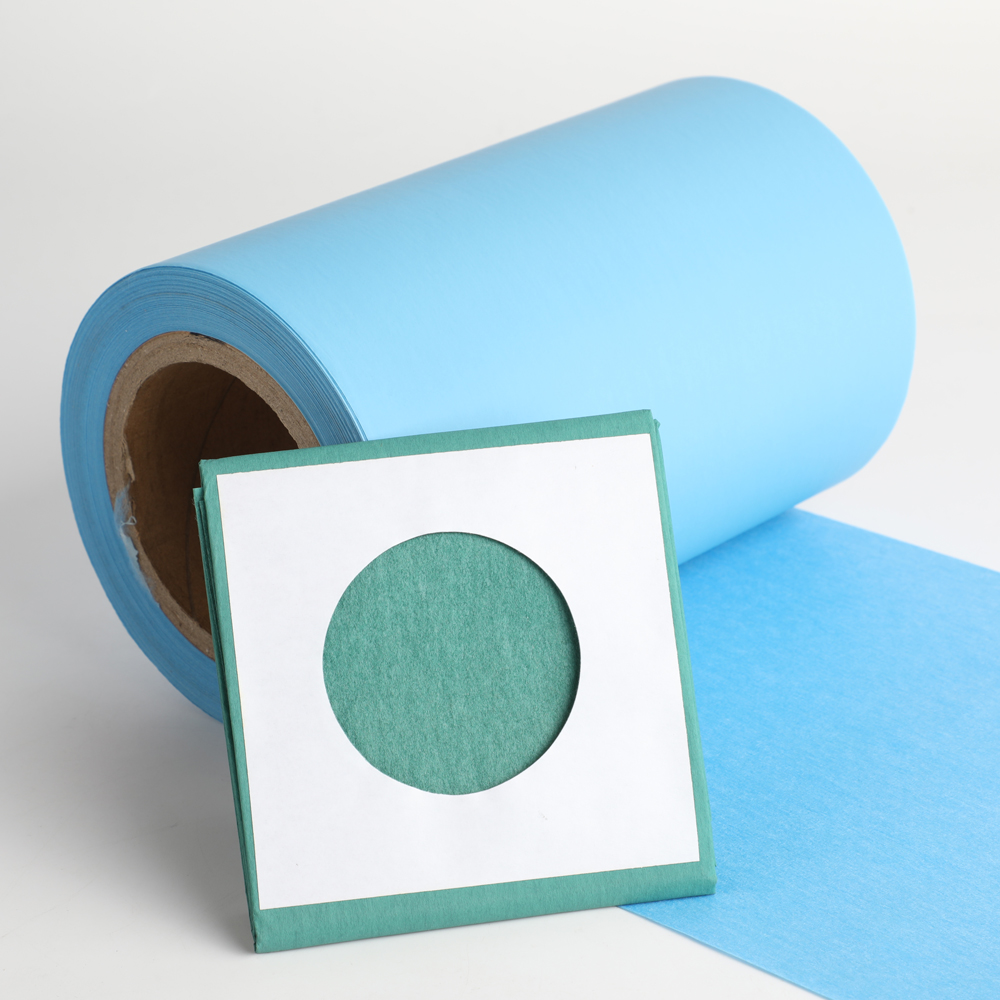

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

Air Filter Media Liquid Filter Media

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

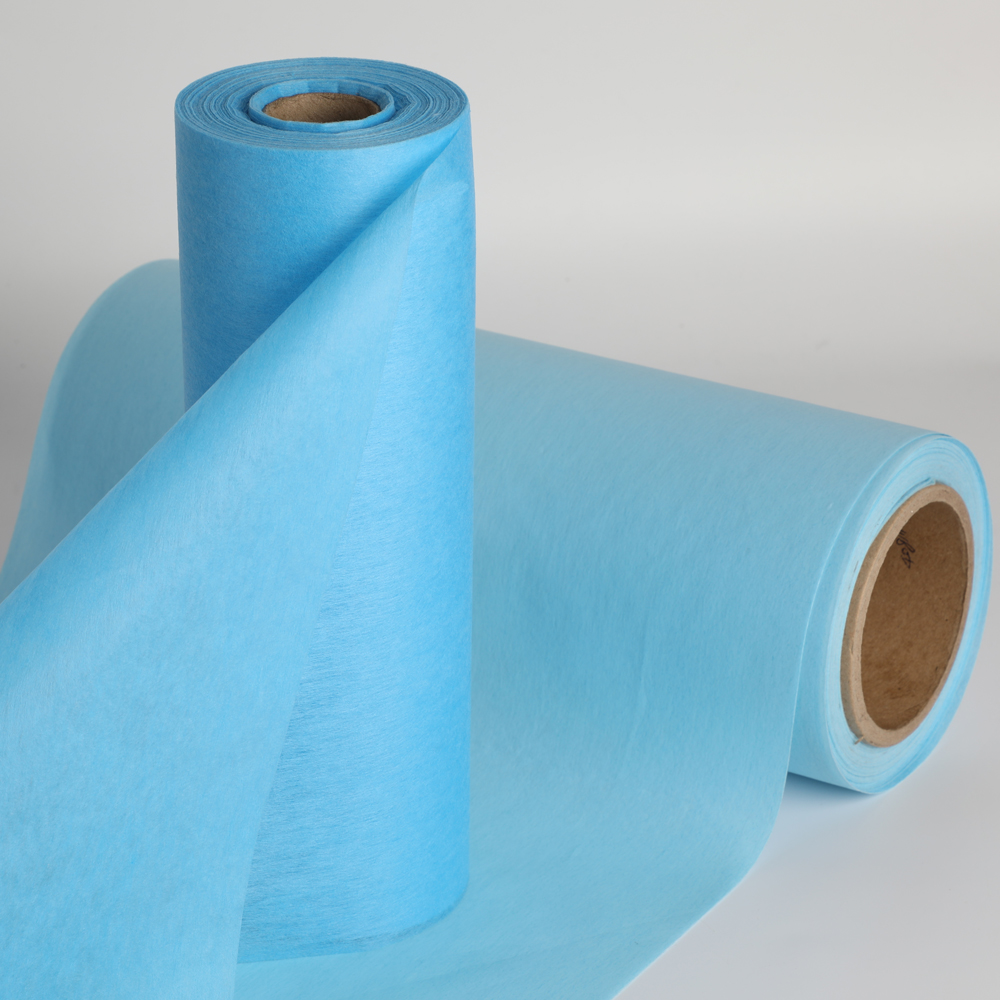

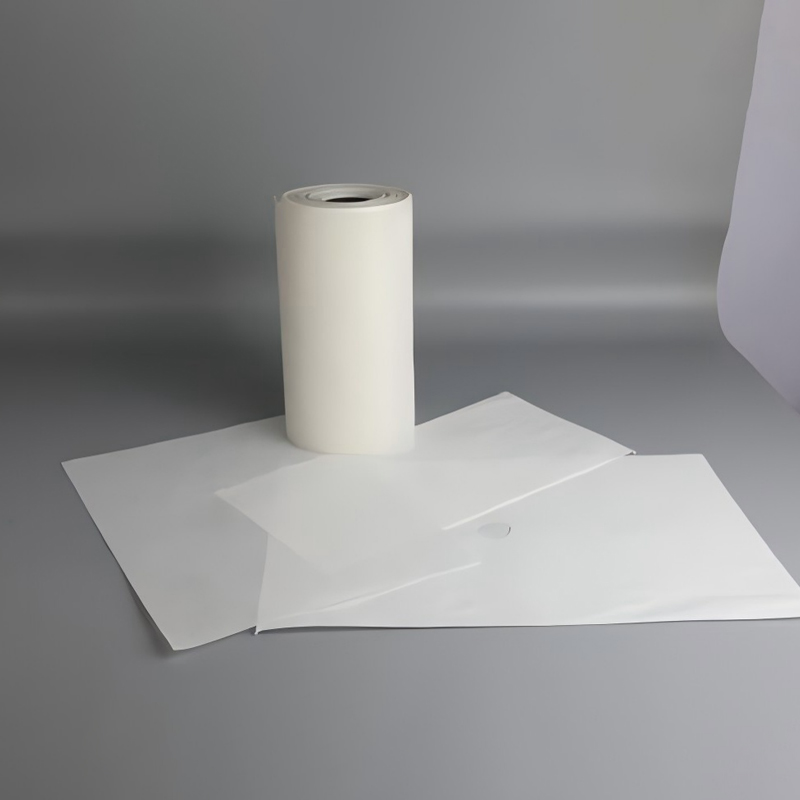

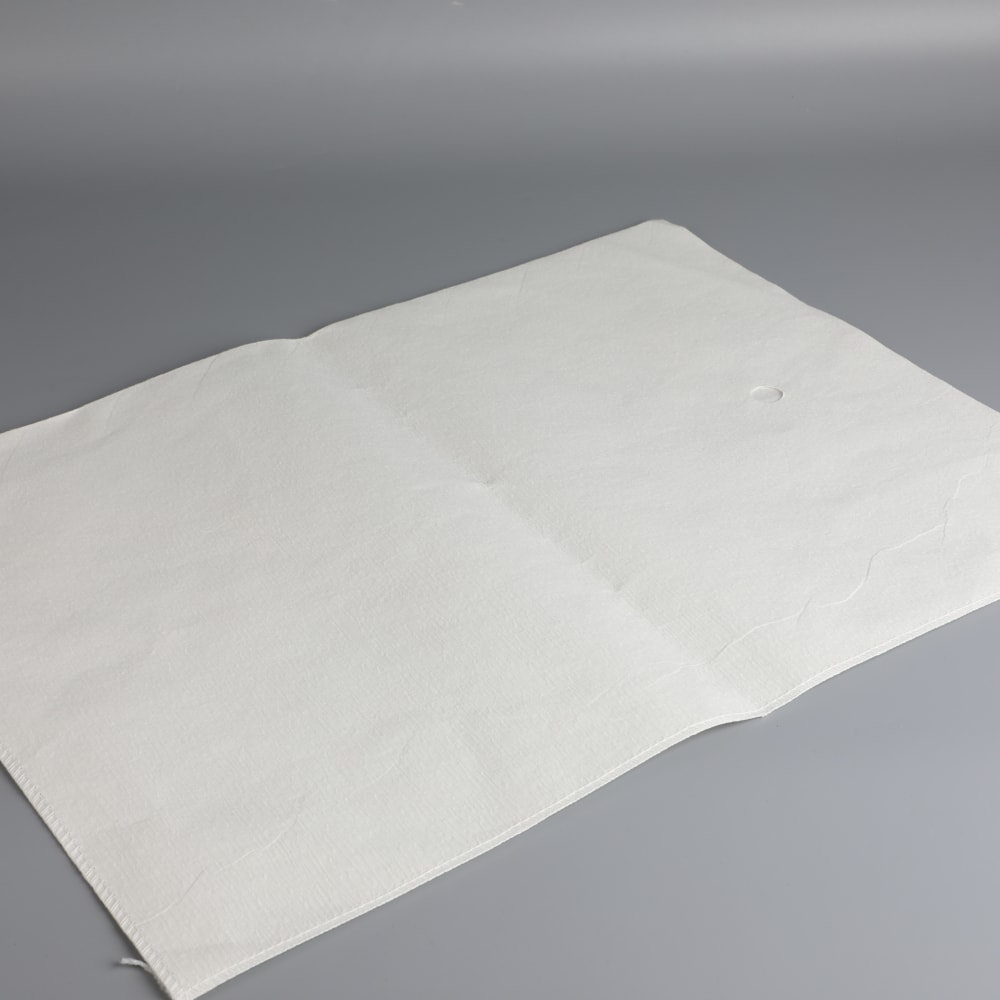

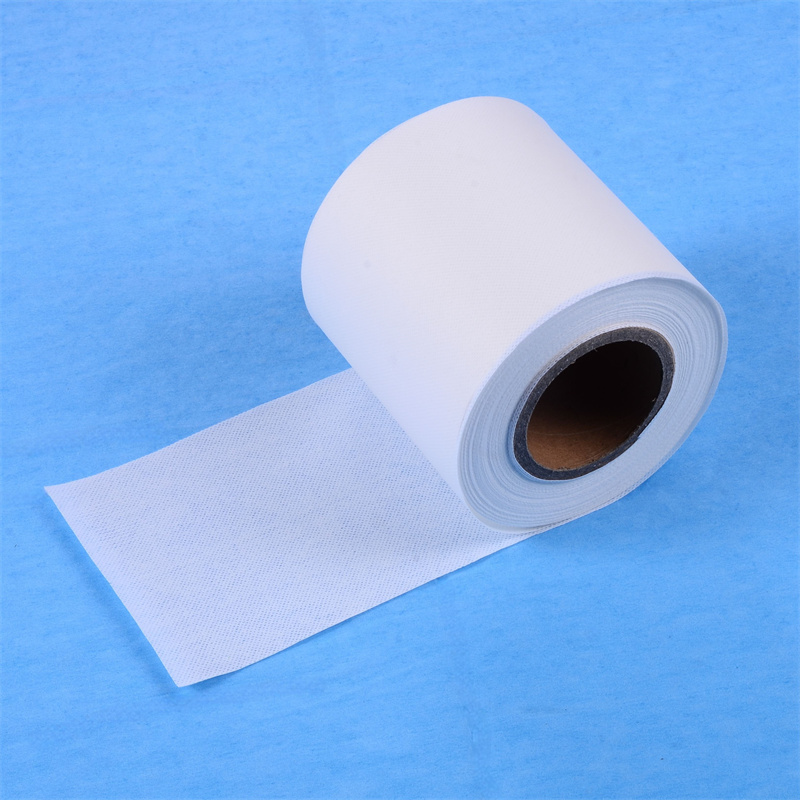

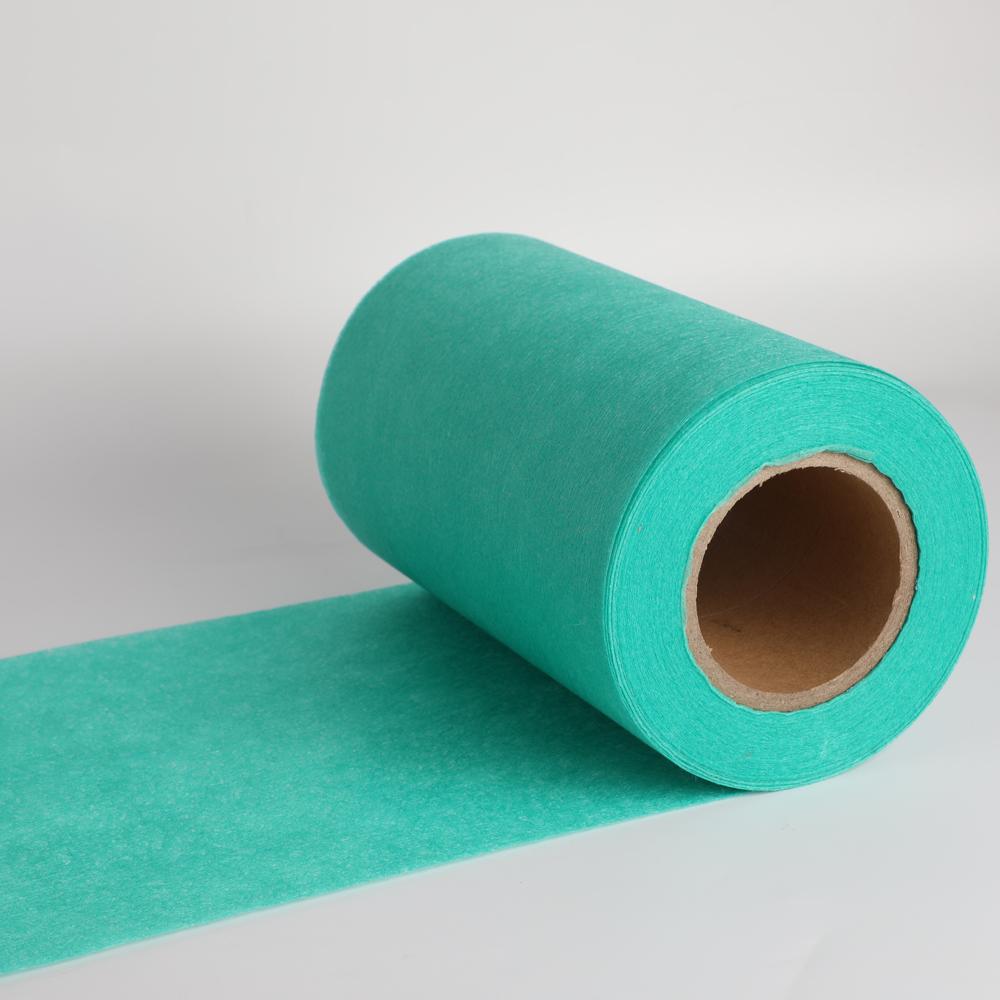

Breathable Film Laminates Nonwoven Interlining

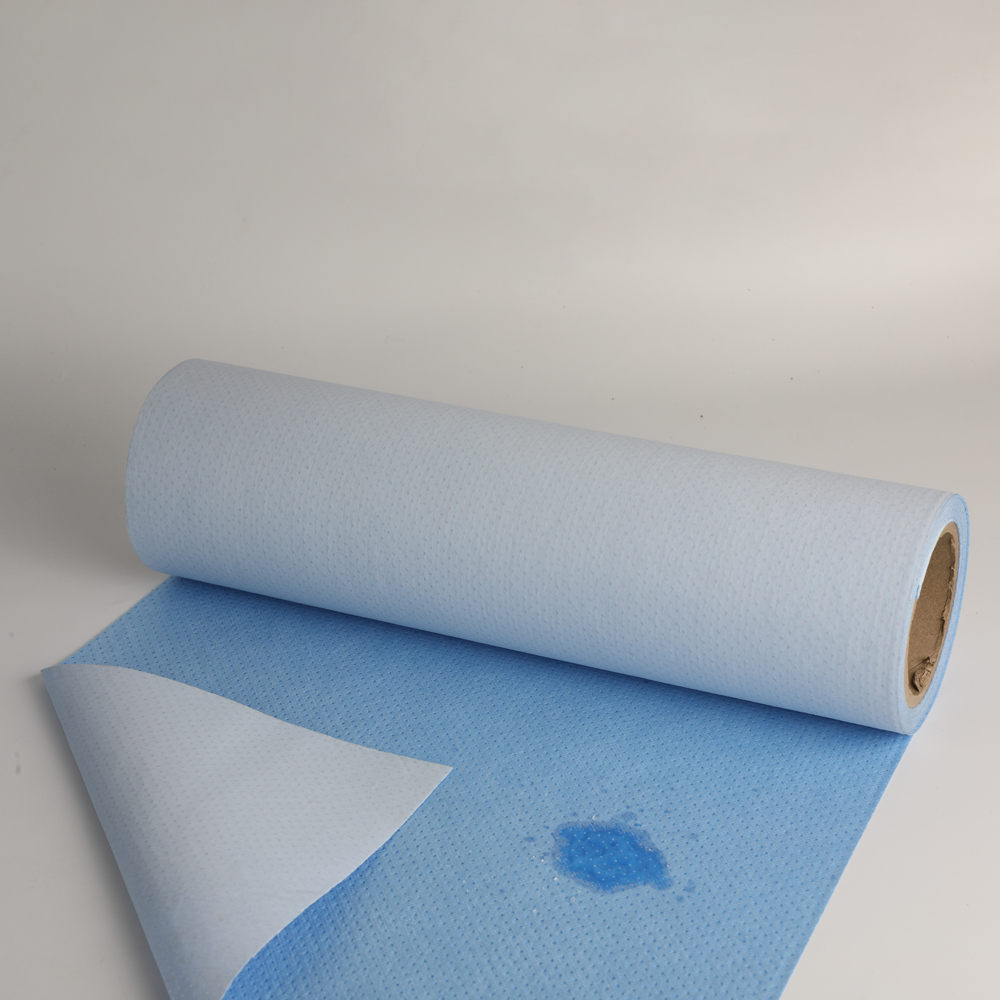

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

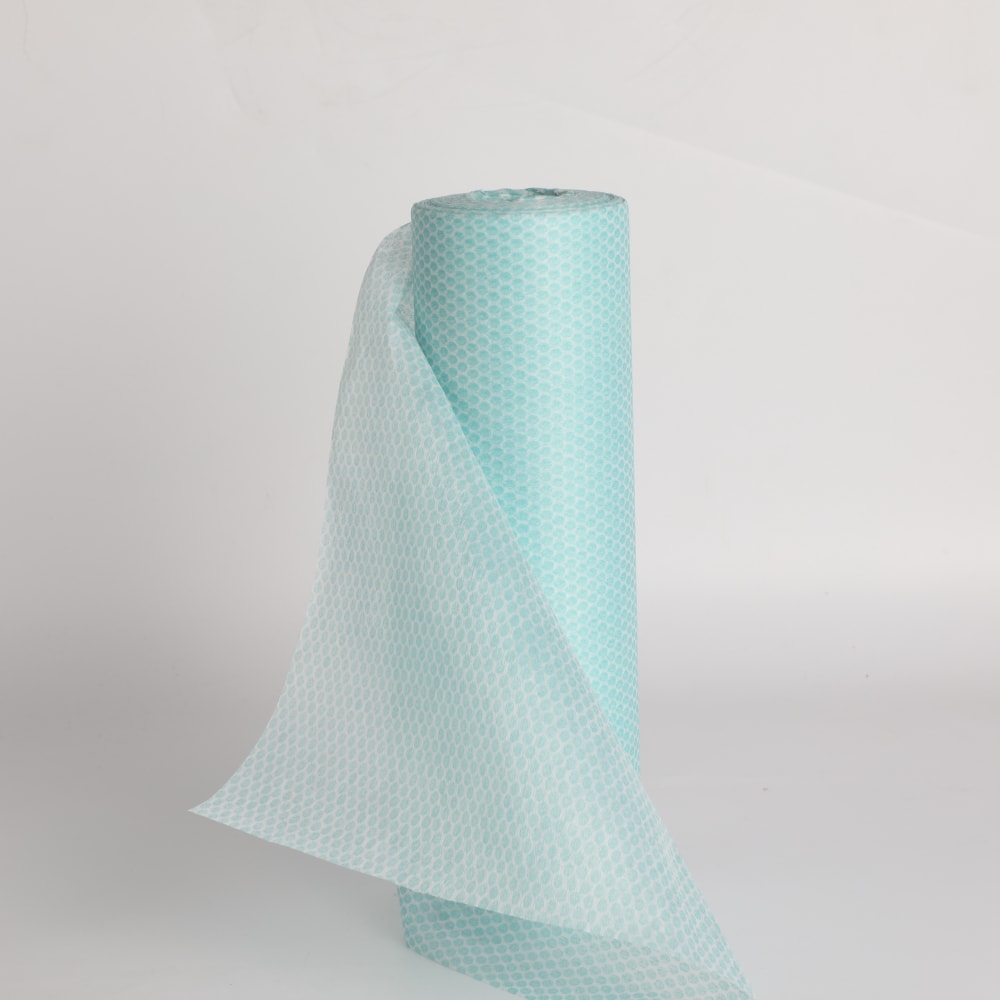

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven