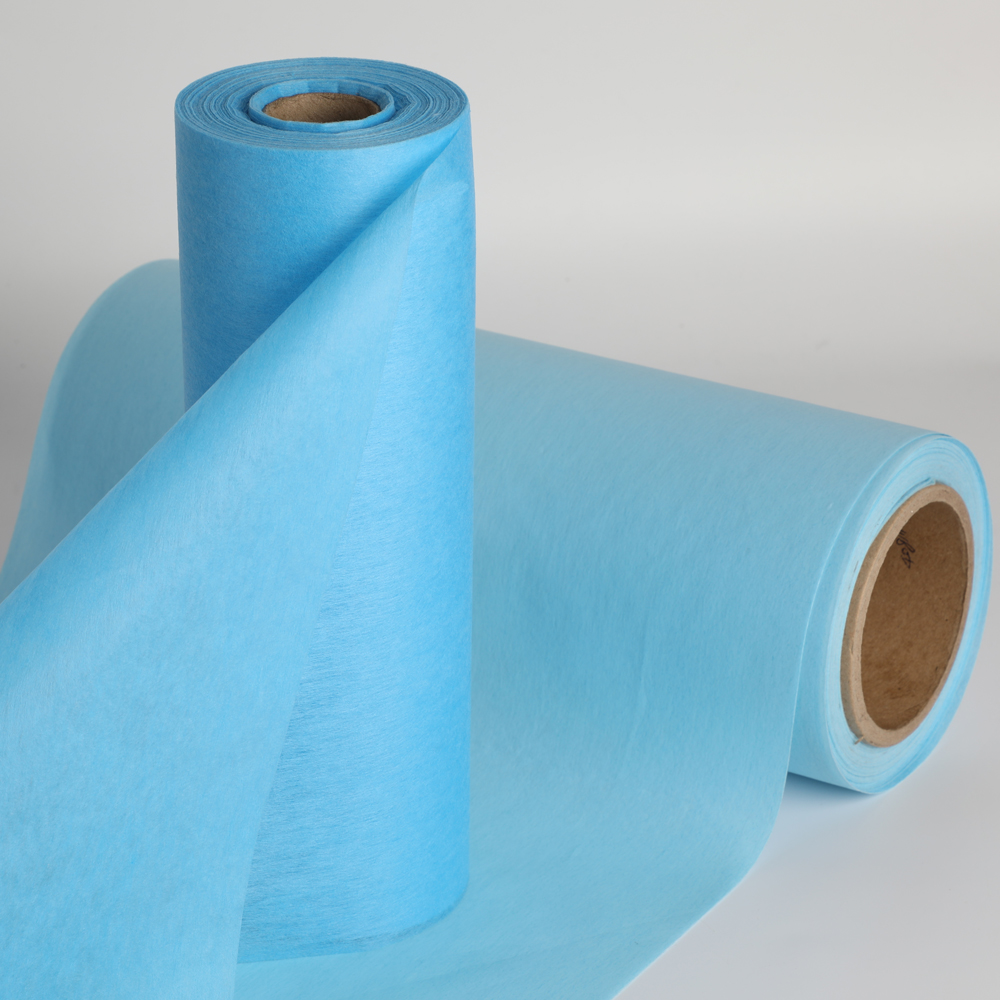

Multi-Use Filtration Nonwoven Fabric

Product Information

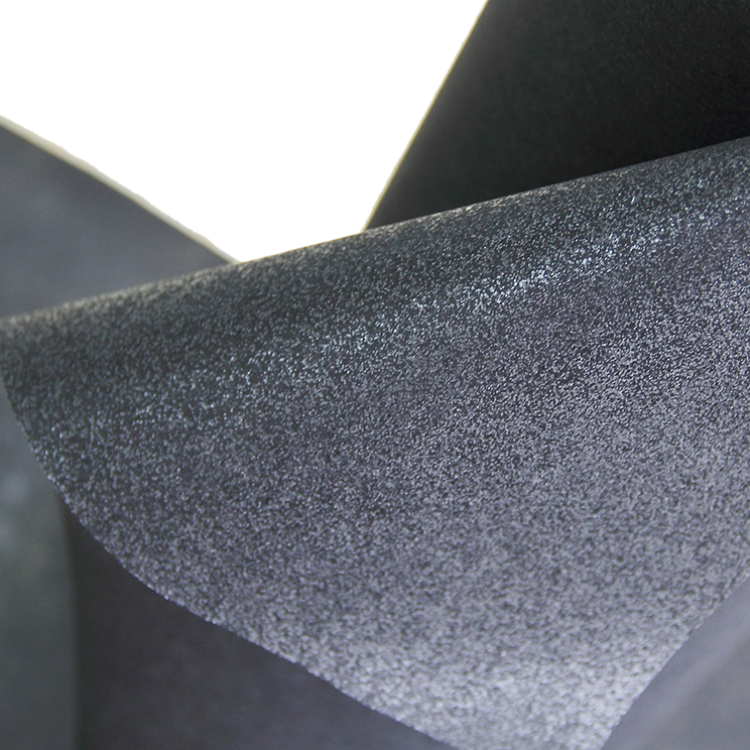

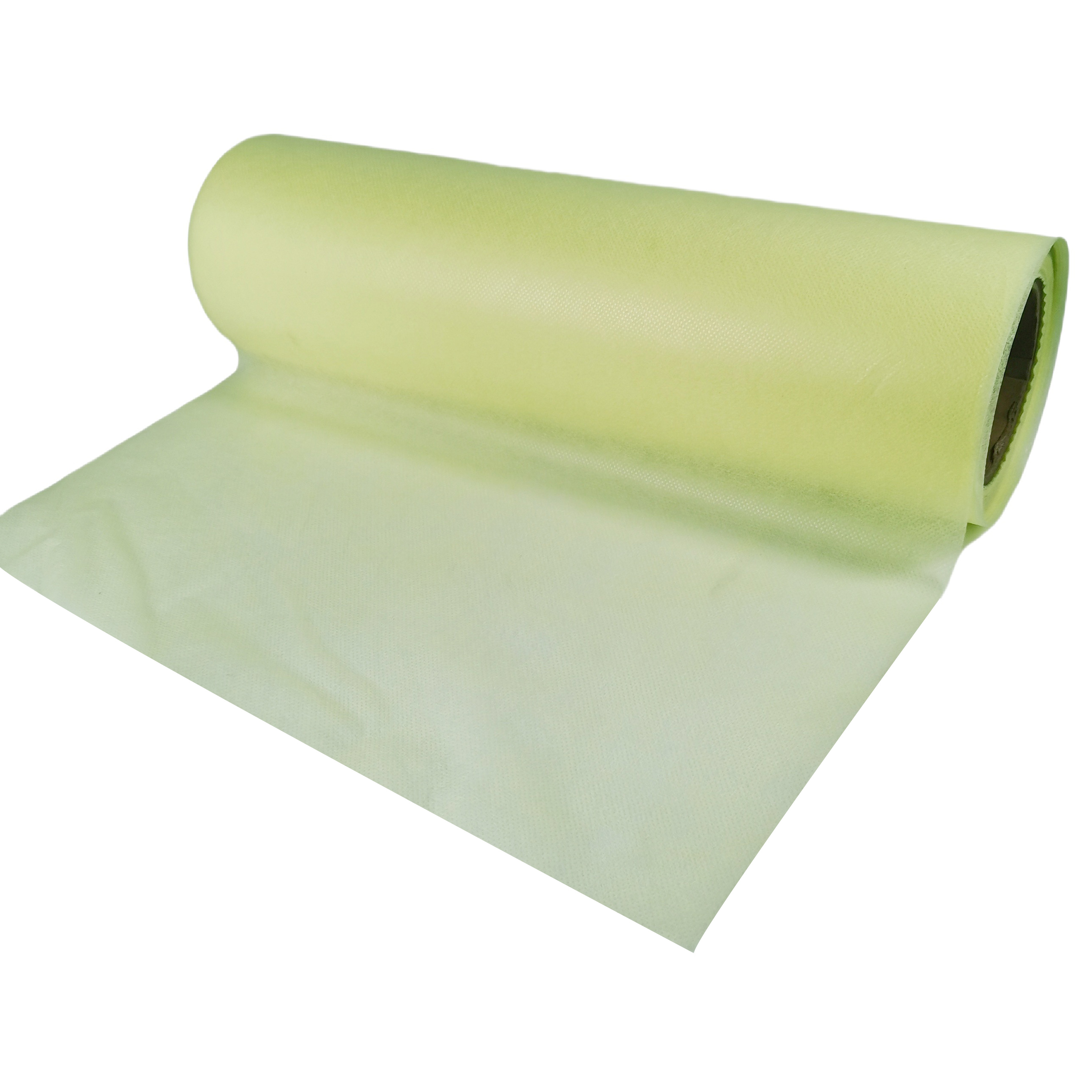

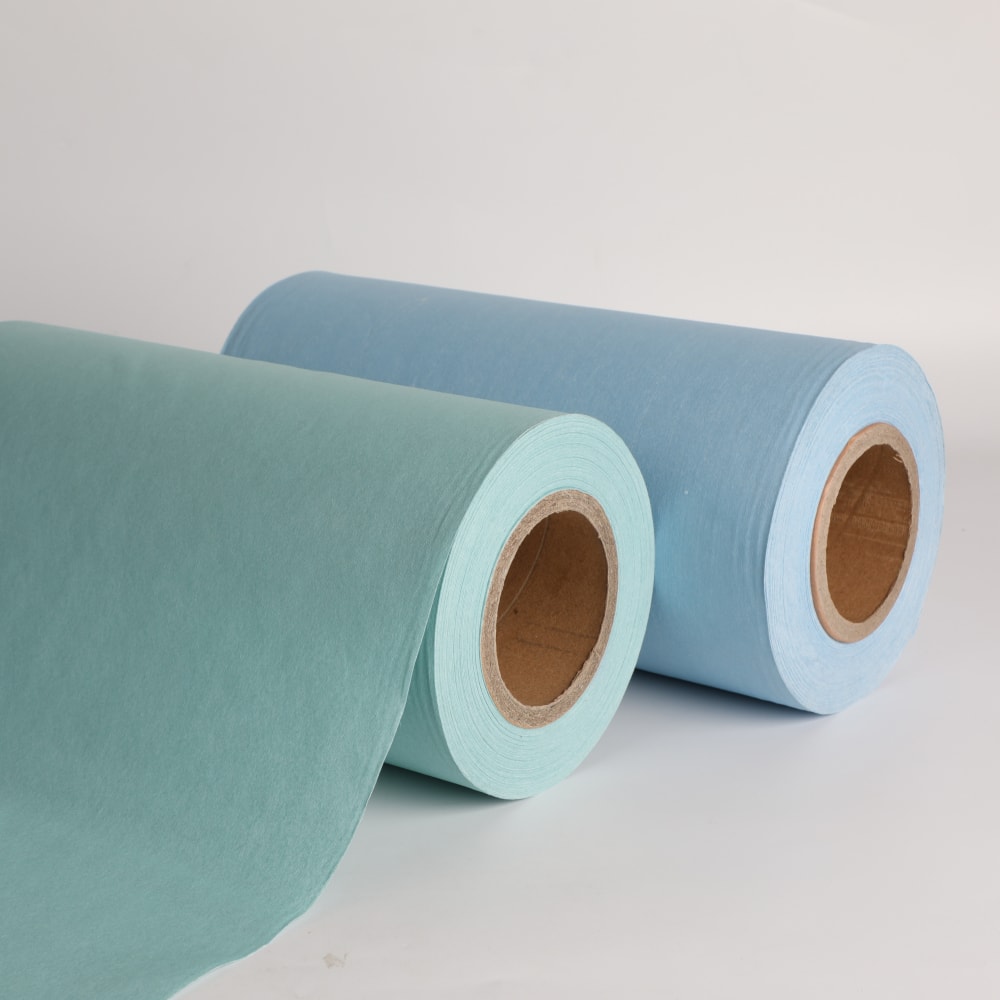

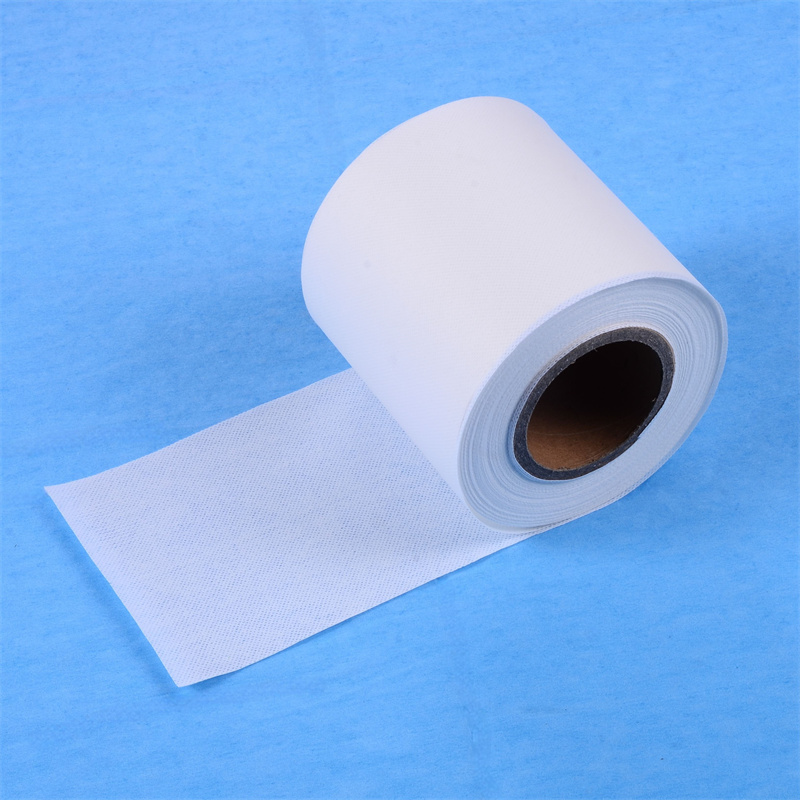

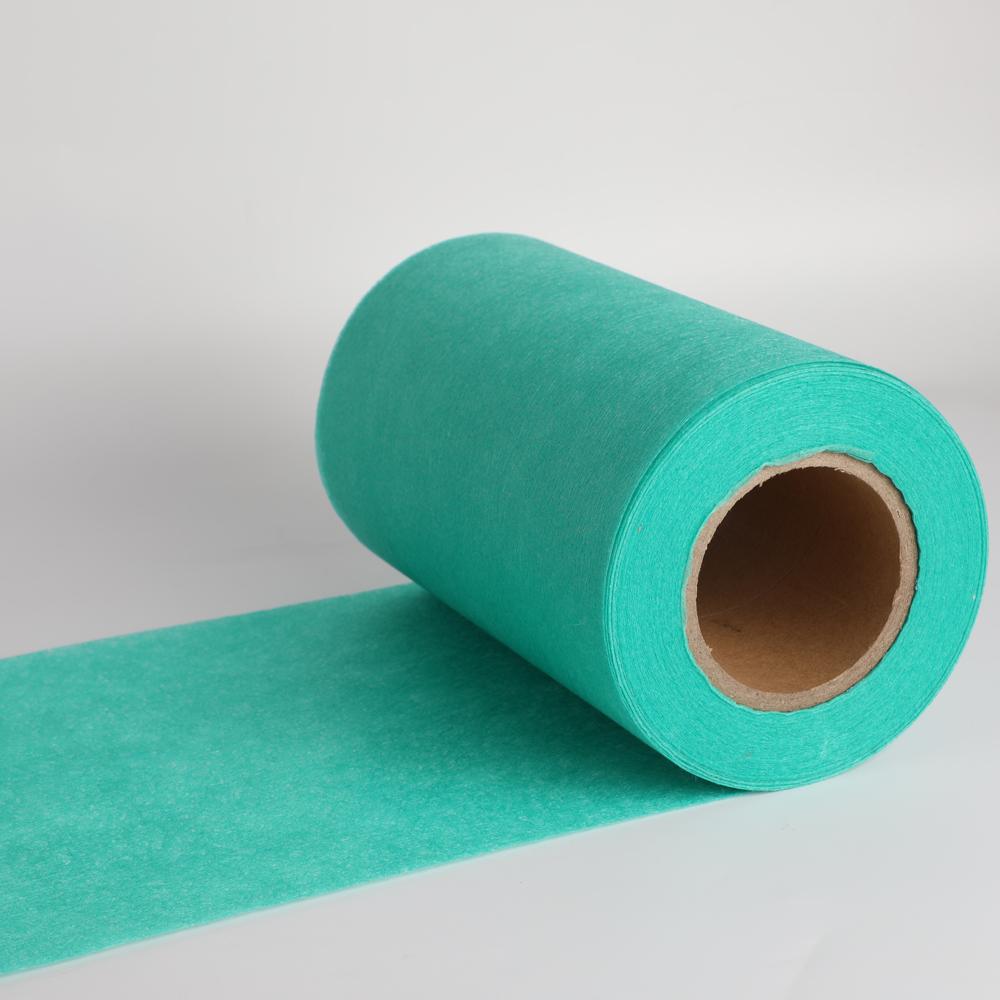

| Item | Filtration Nonwoven |

| Manufacturing Technology | Wet-laid / Chembond |

| Width | Over 150cm |

| Color(s) | White , Green , Purple |

| Weight | 50G ~ 80G |

| Material | Polyester |

| Shelf Life | 365 Days |

| Packing | PE wrapping |

High Strength: Built to withstand rigorous filtration conditions, ensuring long-term and reliable performance.

Exceptional Durability: Resistant to wear and tear, providing extended service life compared to conventional materials.

Polyester Filament Composition: Offers excellent chemical resistance and stability for diverse filtration applications.

Product Features

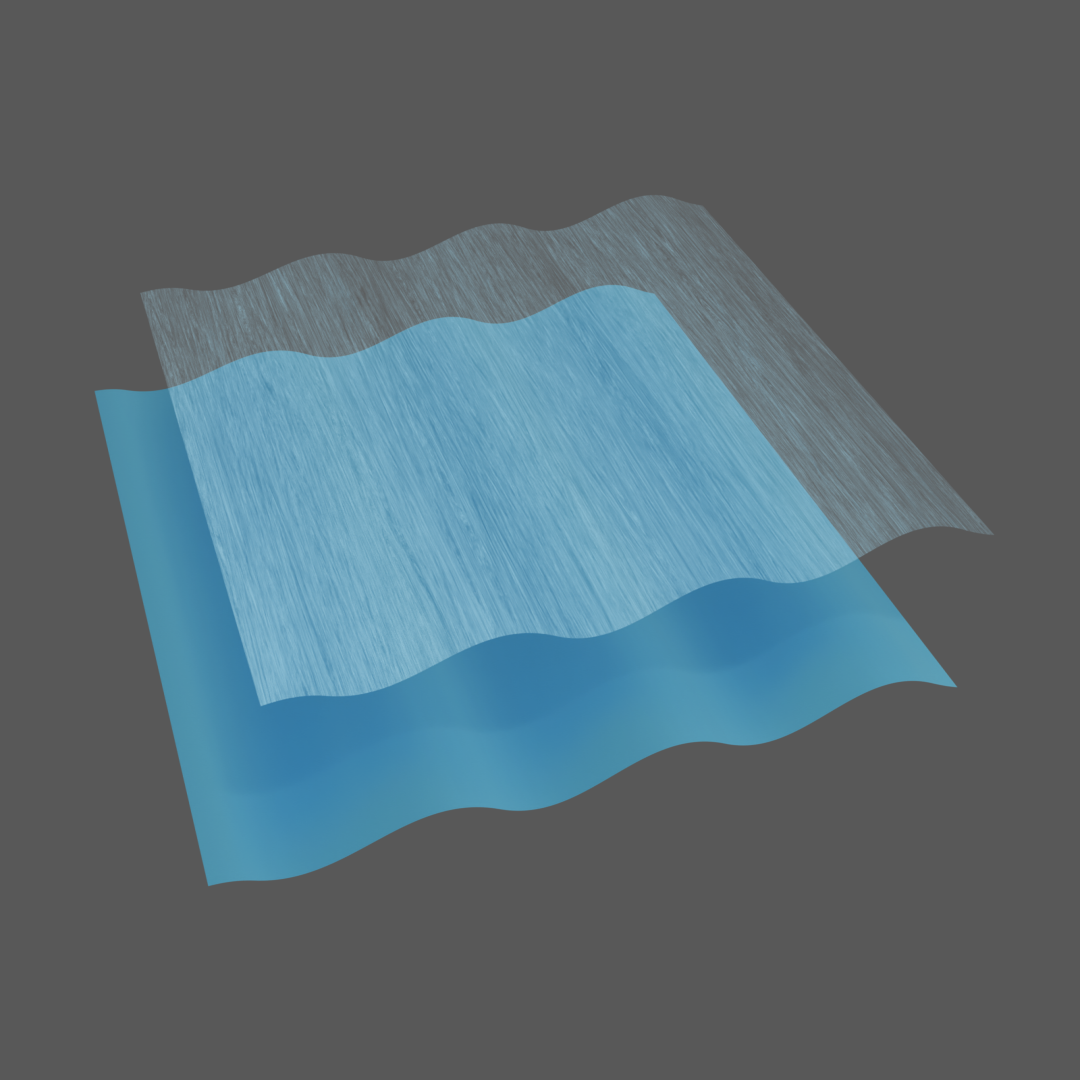

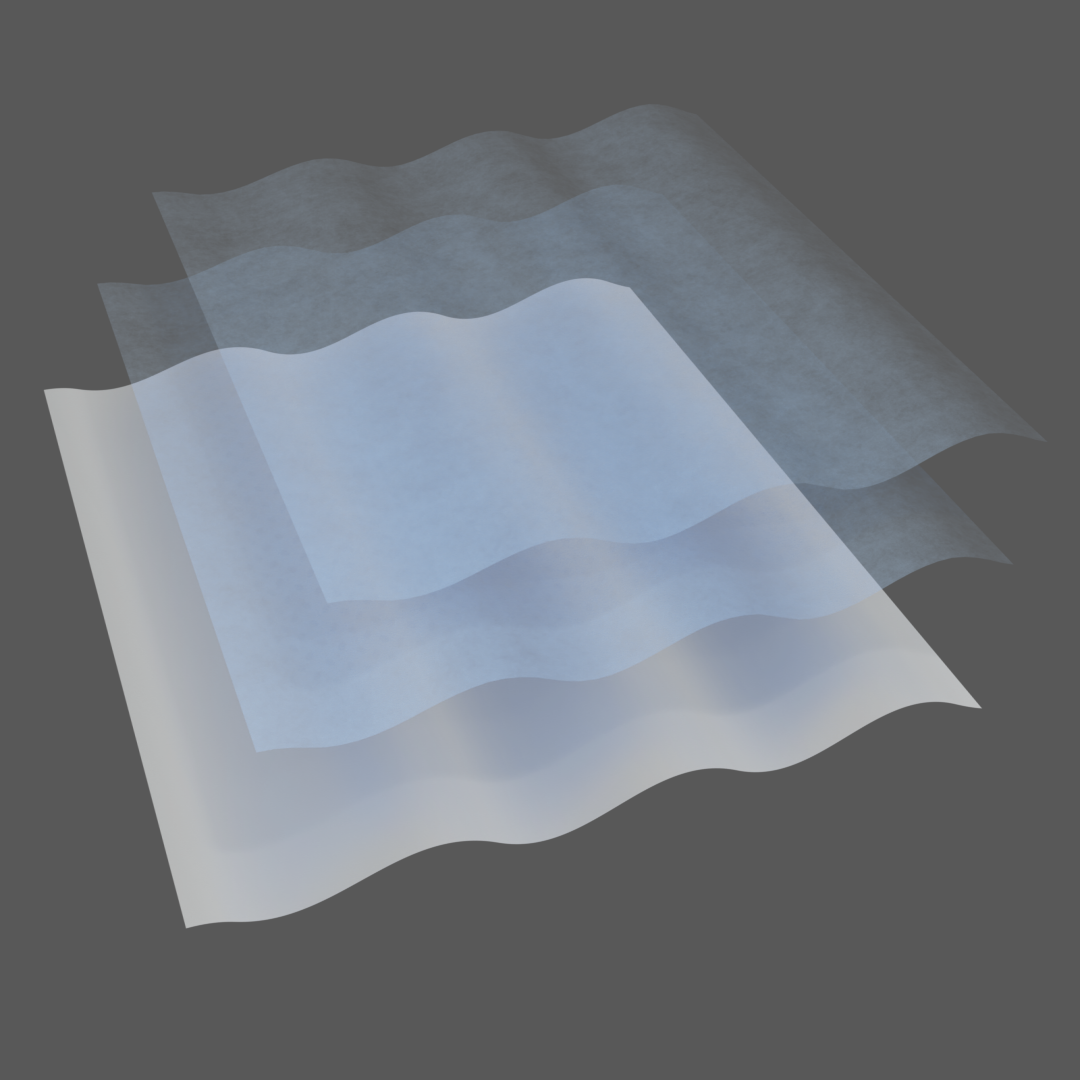

Material Composition and Properties

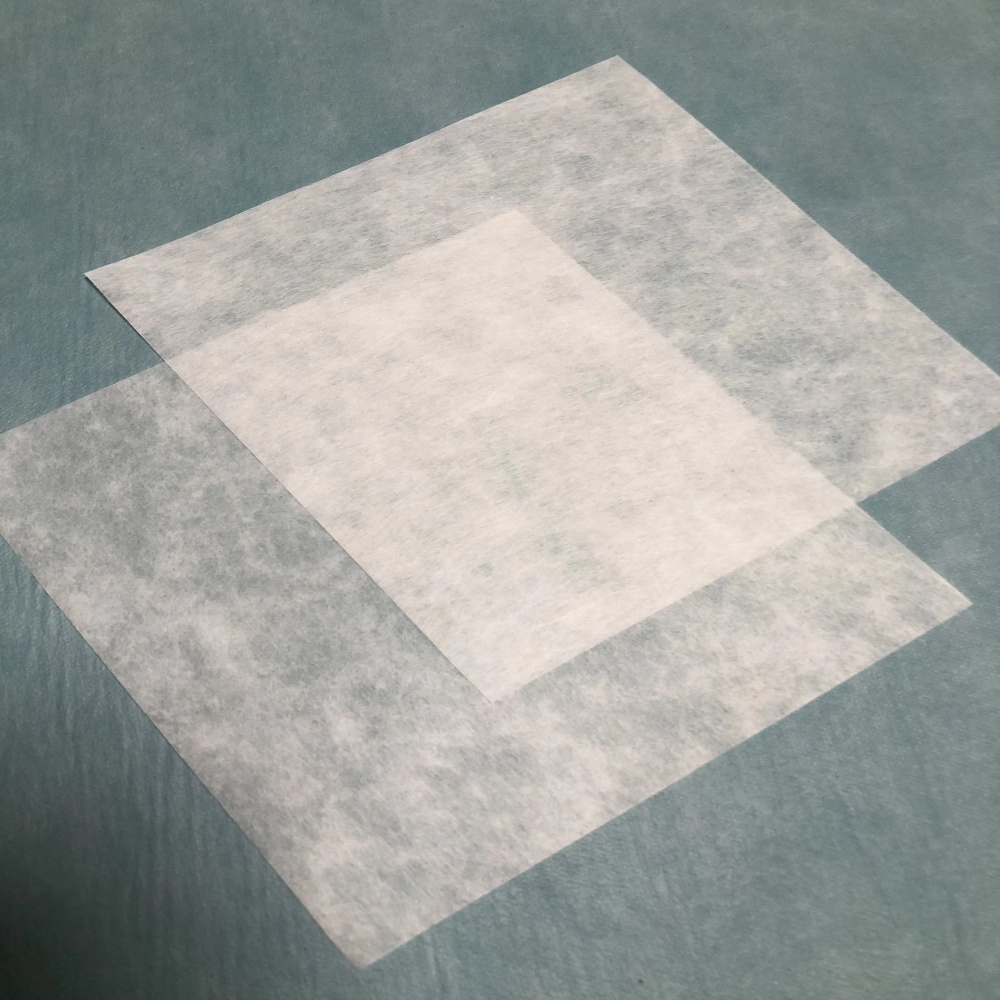

Our filtration nonwoven fabric is meticulously crafted from high-quality polyester long-filament fibers. The use of polyester filaments provides numerous advantages. Firstly, these filaments are known for their remarkable strength, allowing the fabric to endure high-pressure differentials and mechanical stress during the filtration process. This strength is crucial in applications where the filter is subjected to continuous flow of fluids or gases, preventing it from tearing or deforming. Secondly, polyester exhibits excellent chemical resistance, making our nonwoven fabric suitable for handling a wide range of substances. Whether it's acidic, alkaline, or neutral fluids, it can maintain its integrity and filtration efficiency.

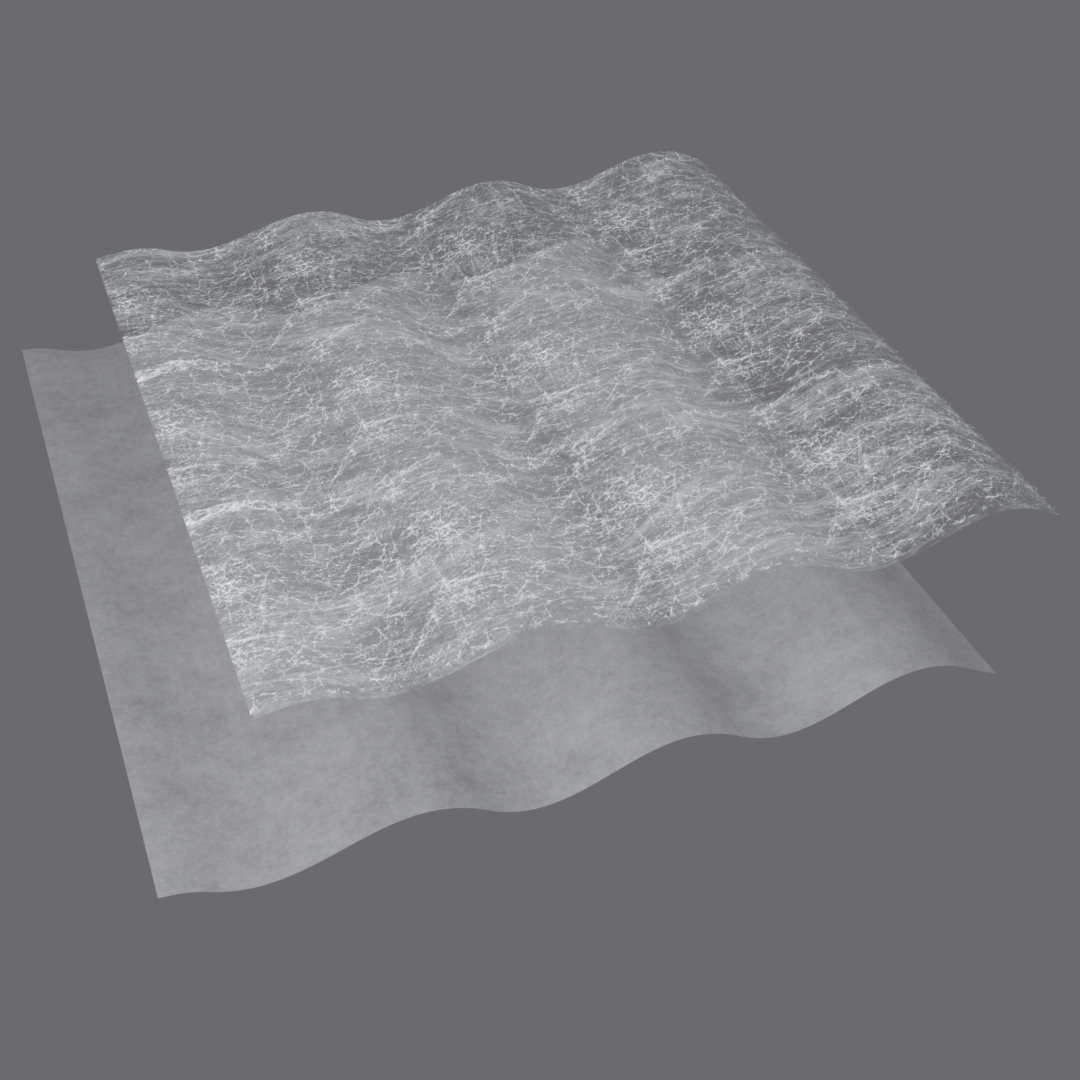

Filtration Efficiency and Precision

In the filtration industry, efficiency and precision are key. Our filter nonwoven fabric is designed to meet and exceed industry standards. The unique fiber structure and manufacturing process result in a fabric with a precisely controlled pore size distribution. This enables it to effectively capture particles of various sizes, from fine dust and pollen to larger debris. For instance, in air filtration systems, it can efficiently remove airborne contaminants, providing cleaner air for indoor environments. In liquid filtration, it can trap suspended solids, ensuring the purity of the filtrate. The filtration efficiency can be further customized based on specific customer requirements, making it a versatile solution for different filtration needs.

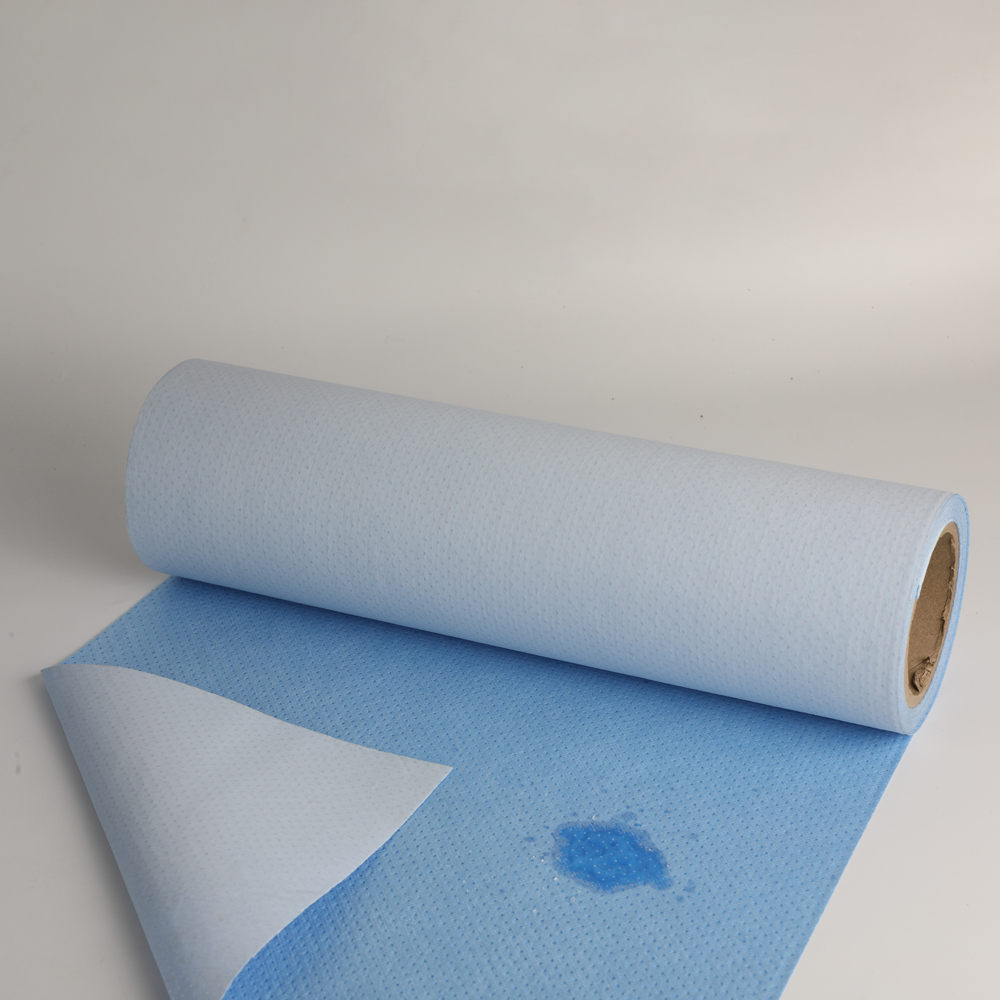

Durability and Longevity

The durability of our filtration nonwoven fabric is a standout feature. Thanks to its high-strength polyester filament construction, it can withstand repeated use and cleaning cycles. In industrial filtration applications, where filters are often replaced frequently due to wear and tear, our product offers a cost-effective alternative. It doesn't degrade easily under harsh operating conditions, such as high temperatures, humidity, or abrasive substances. This longevity not only reduces the need for frequent replacements but also minimizes downtime in production processes. For example, in HVAC systems, a durable filter can maintain optimal performance for an extended period, reducing energy consumption and maintenance costs.

Applications in the Filter Industry

This versatile filter nonwoven fabric finds extensive use in various sectors of the filter industry. In automotive filtration, it's used in air filters for engines and cabin air systems, protecting the engine from harmful particles and providing passengers with clean air. In water treatment, it's a crucial component in membrane filters, helping to purify water for drinking and industrial use. In industrial ventilation systems, it ensures that the air circulating in factories and workshops is free from pollutants.

Multi Laminates

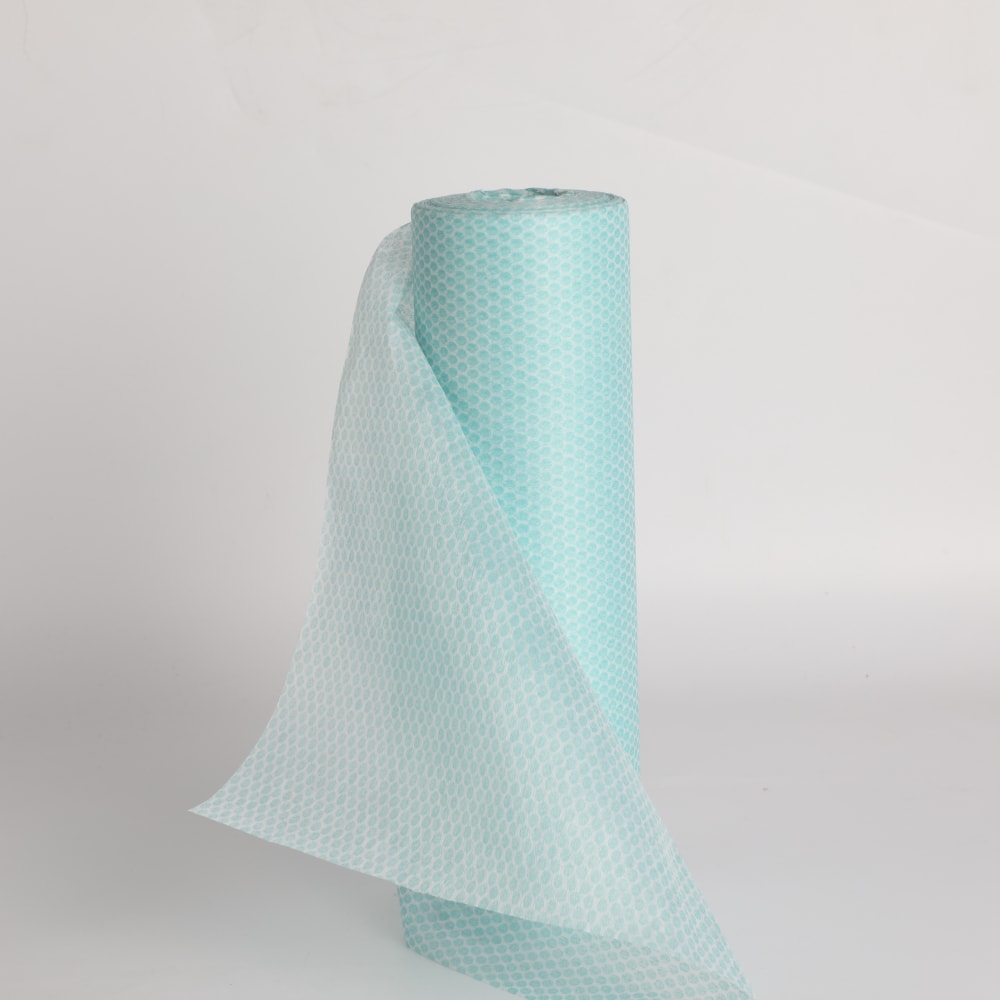

Multi Laminates Spunlace Nonwoven Laminates

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

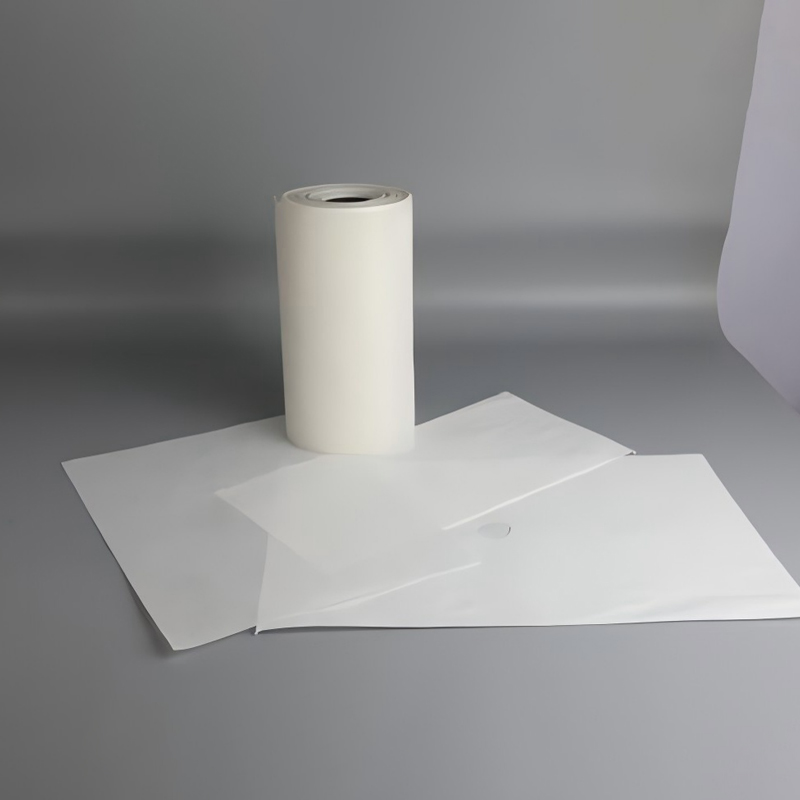

Air Filter Media Liquid Filter Media

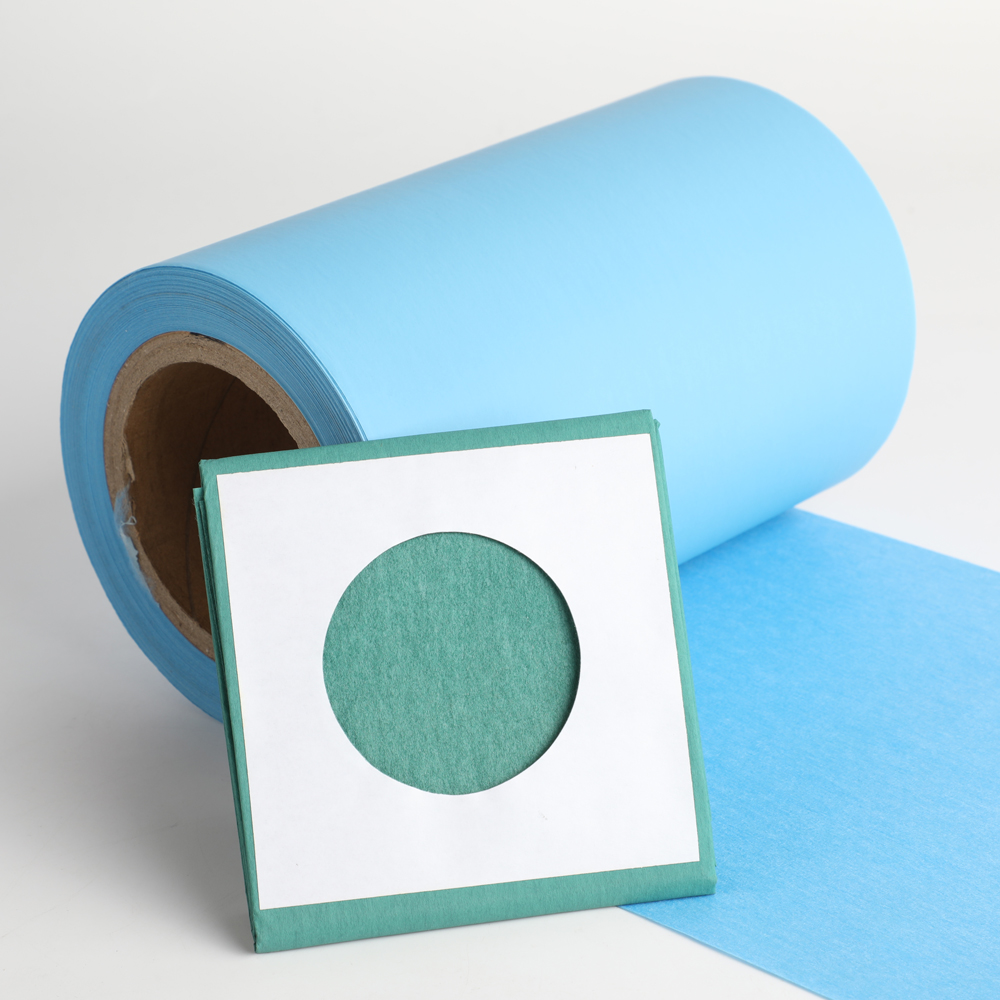

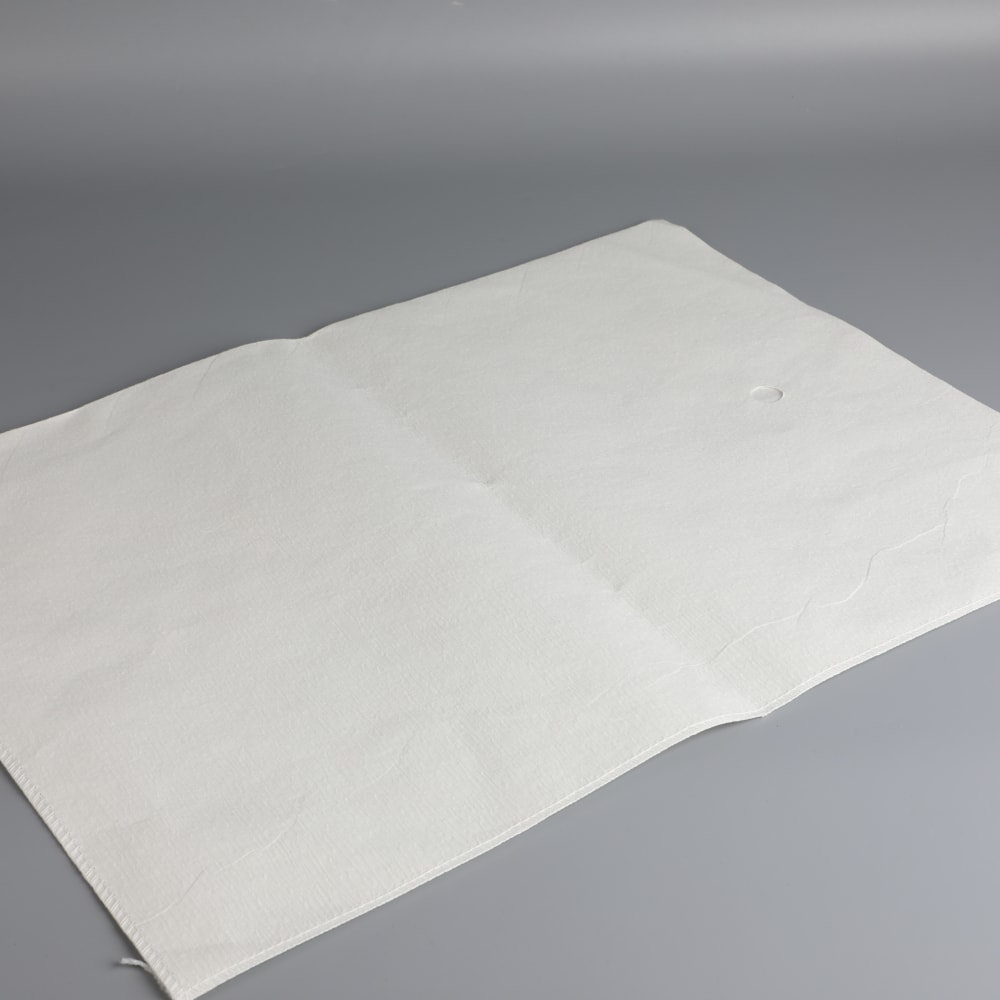

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

Breathable Film Laminates Nonwoven Interlining

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven