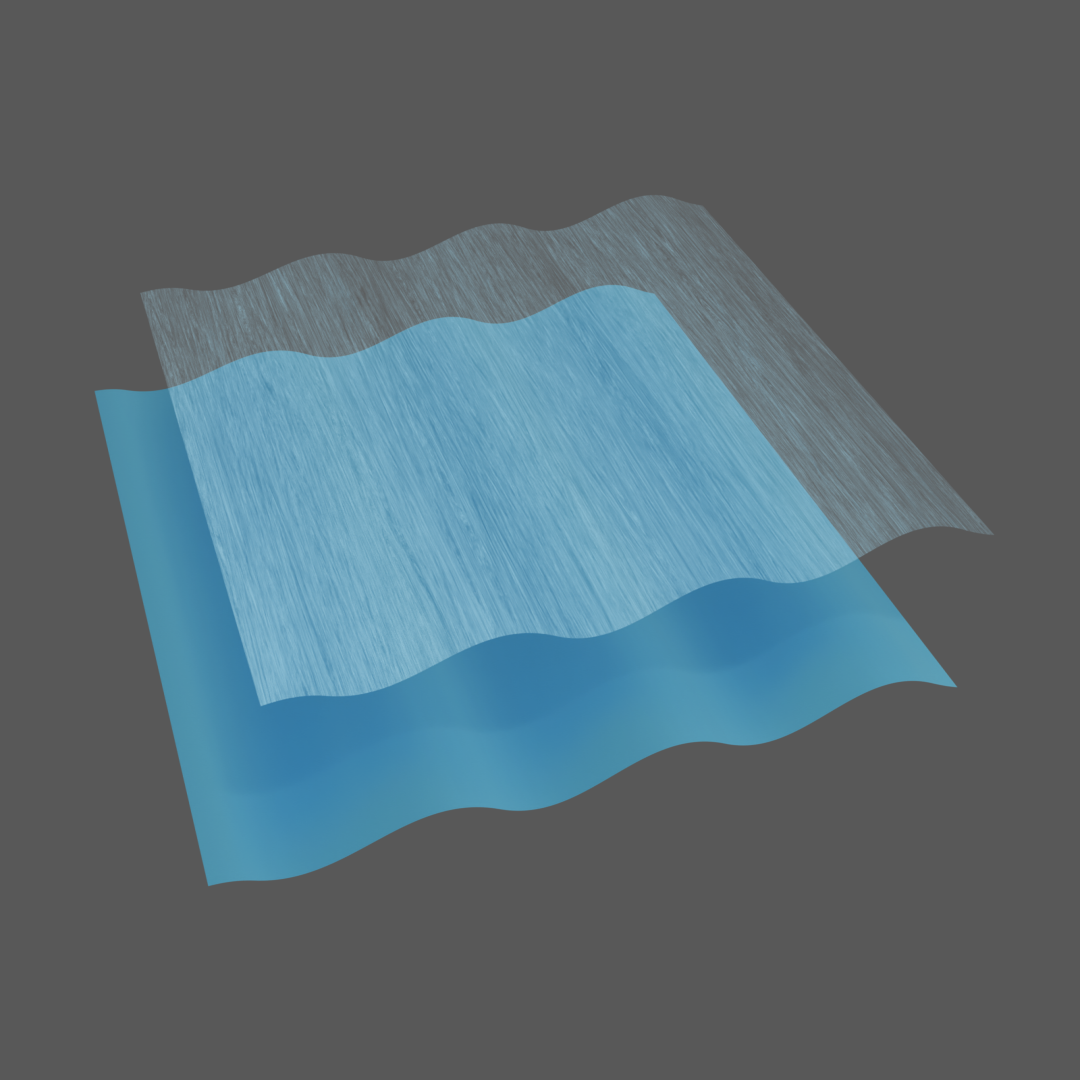

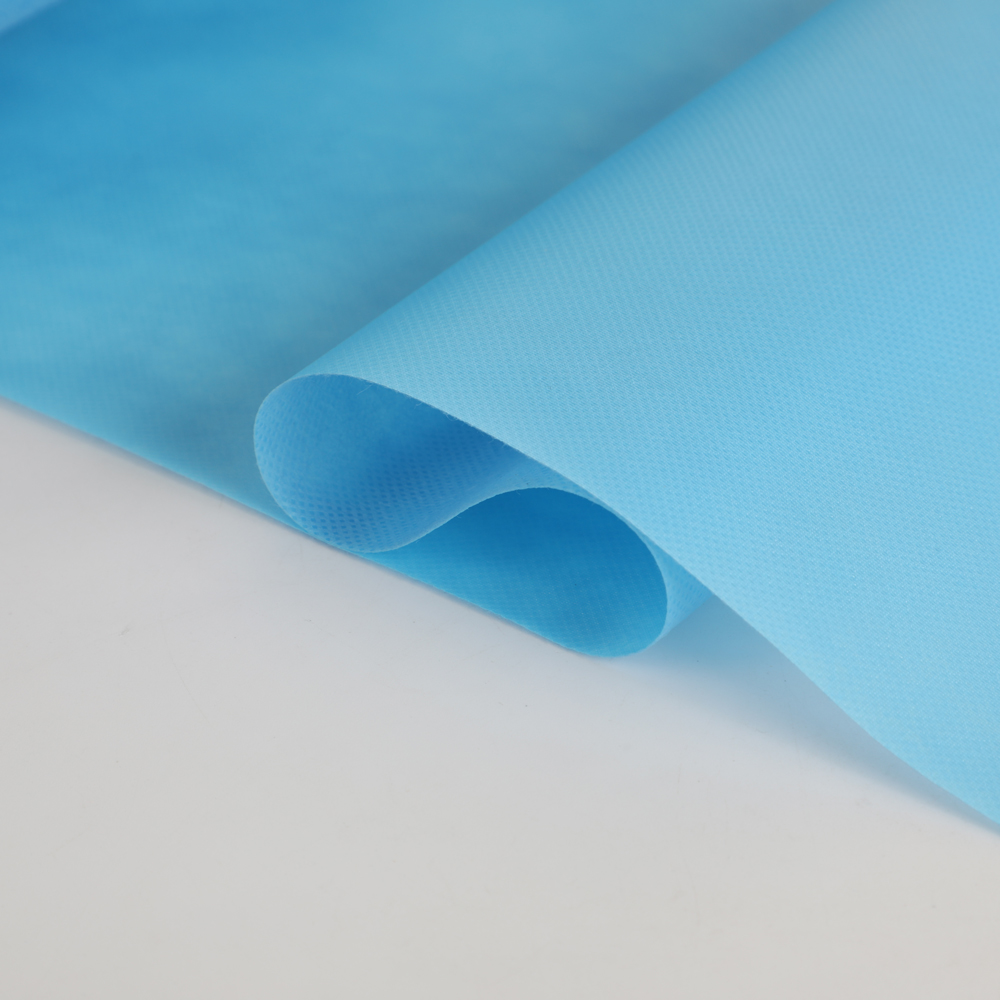

Hotmelt laminated Hydrophilic PP Nonwoven

Product Information

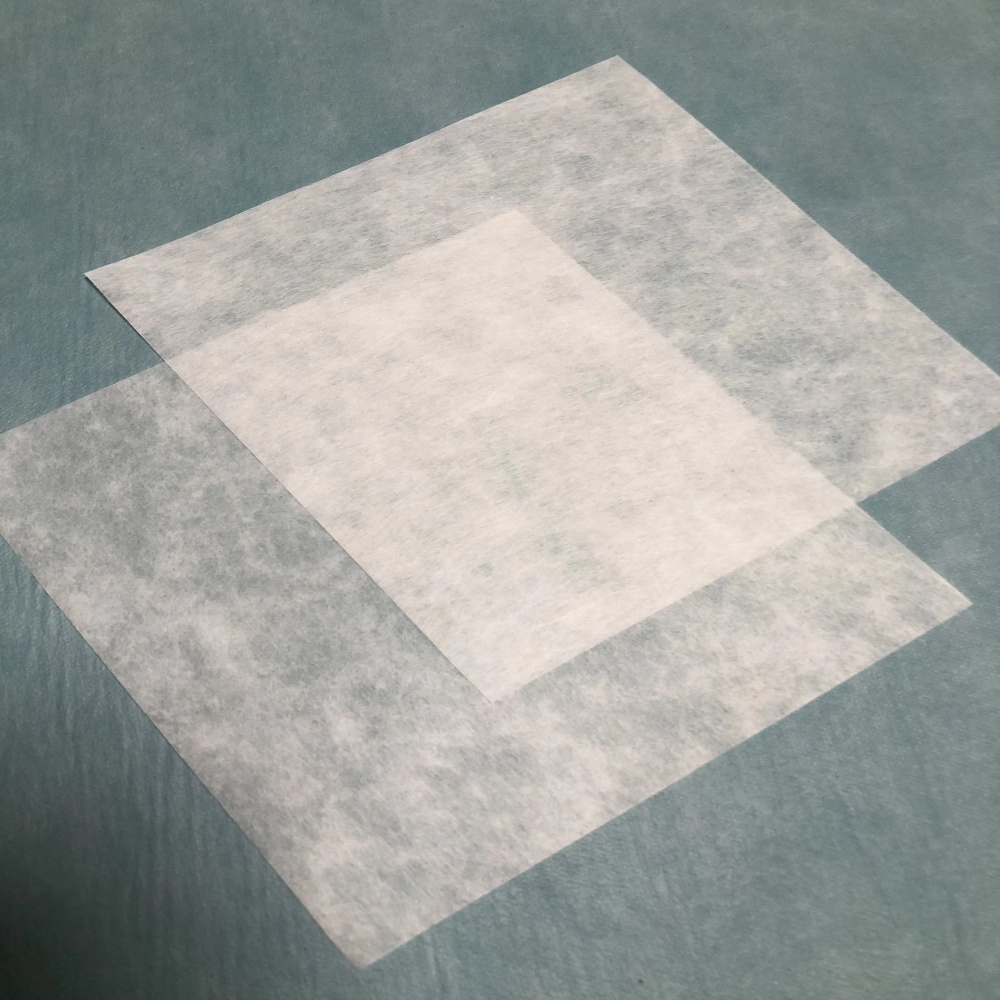

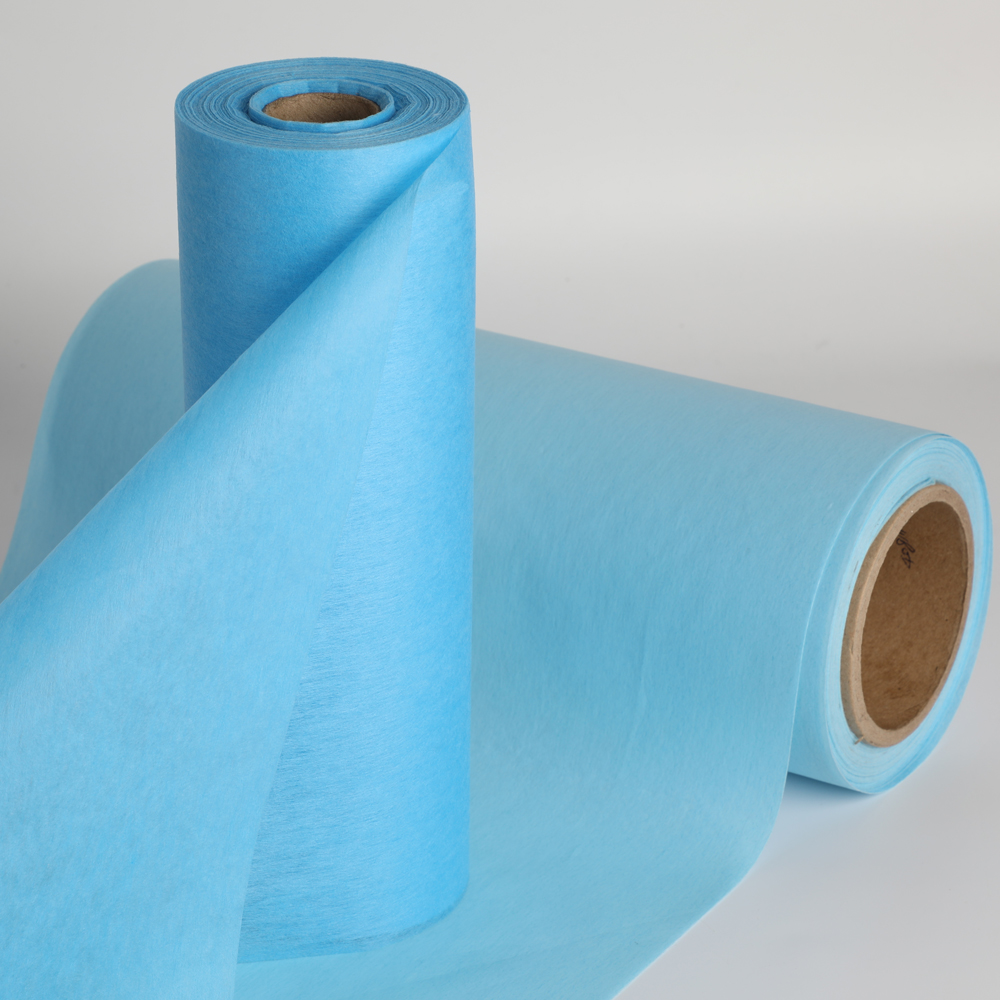

| Item | Hydrophilic PP Laminates |

| Manufacturing Technology | Hotmelt laminated |

| Width | Under 240 cm |

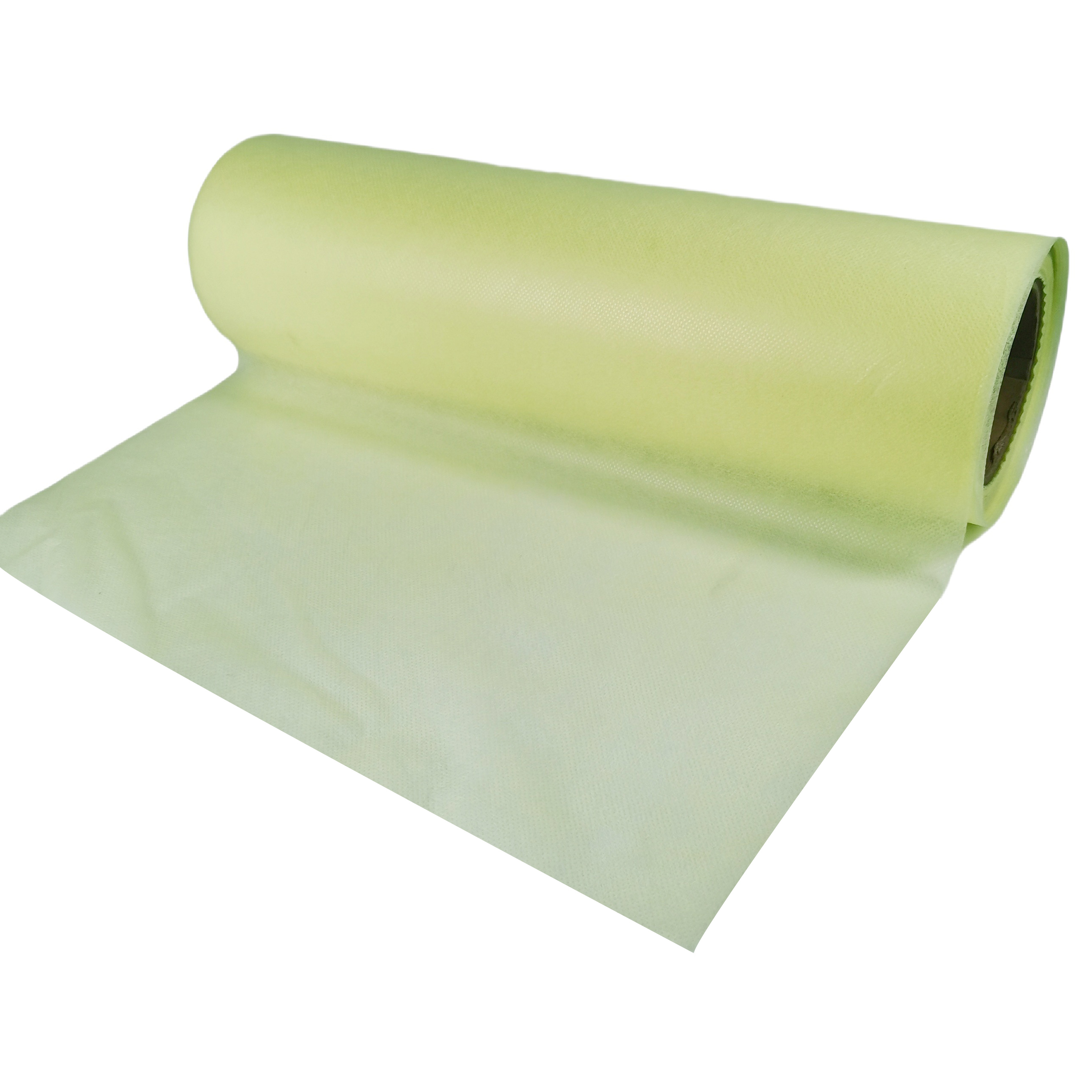

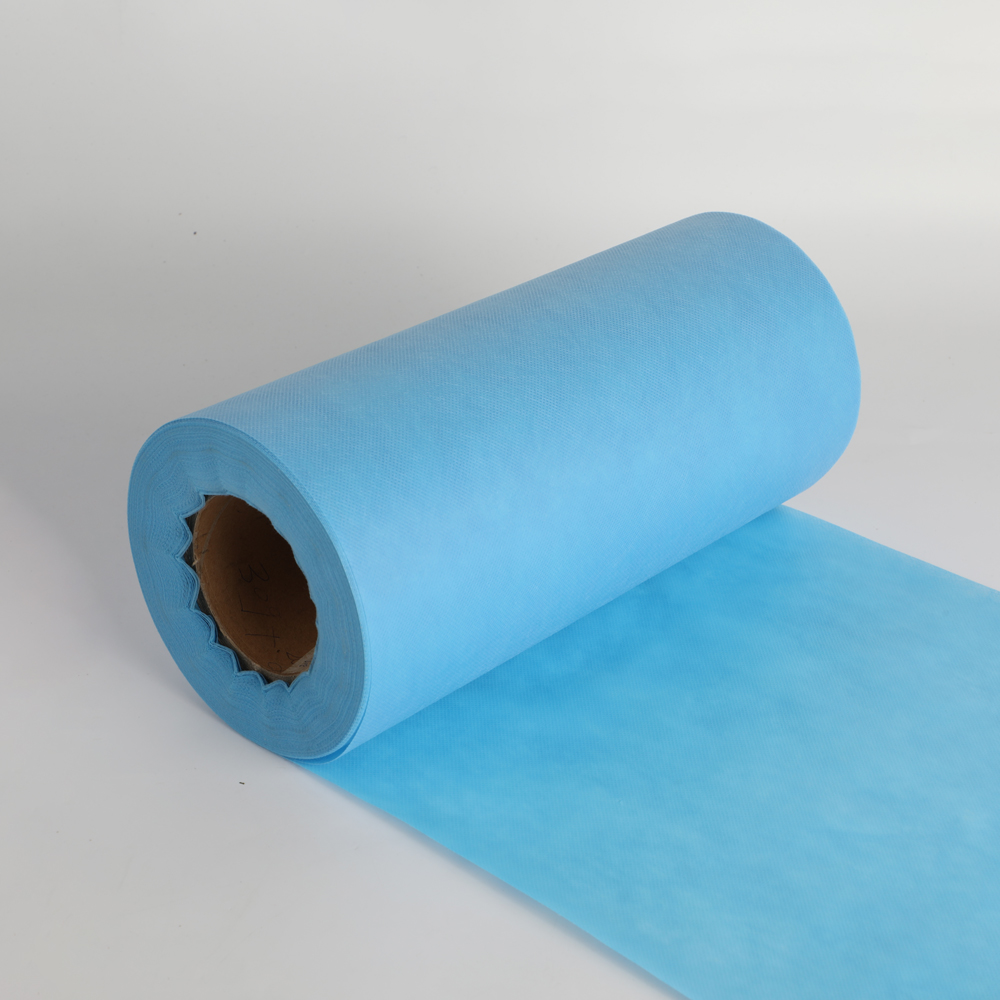

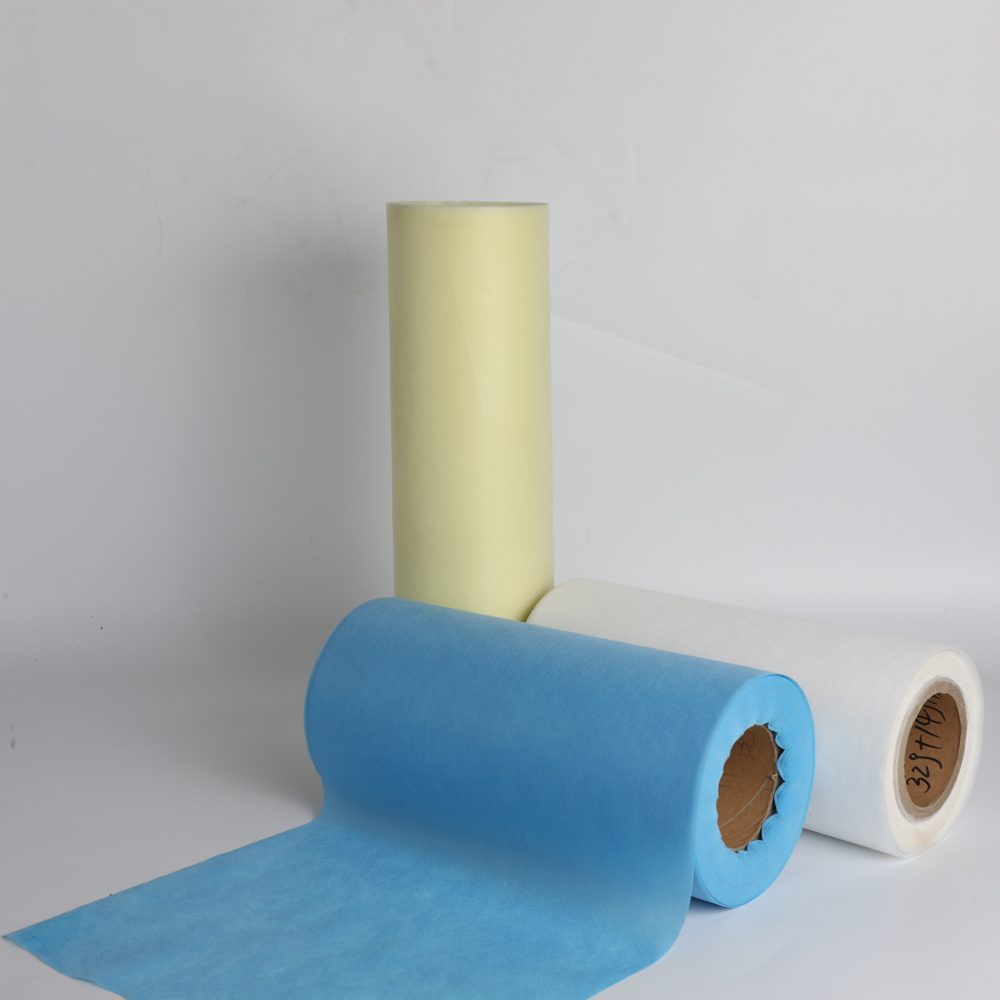

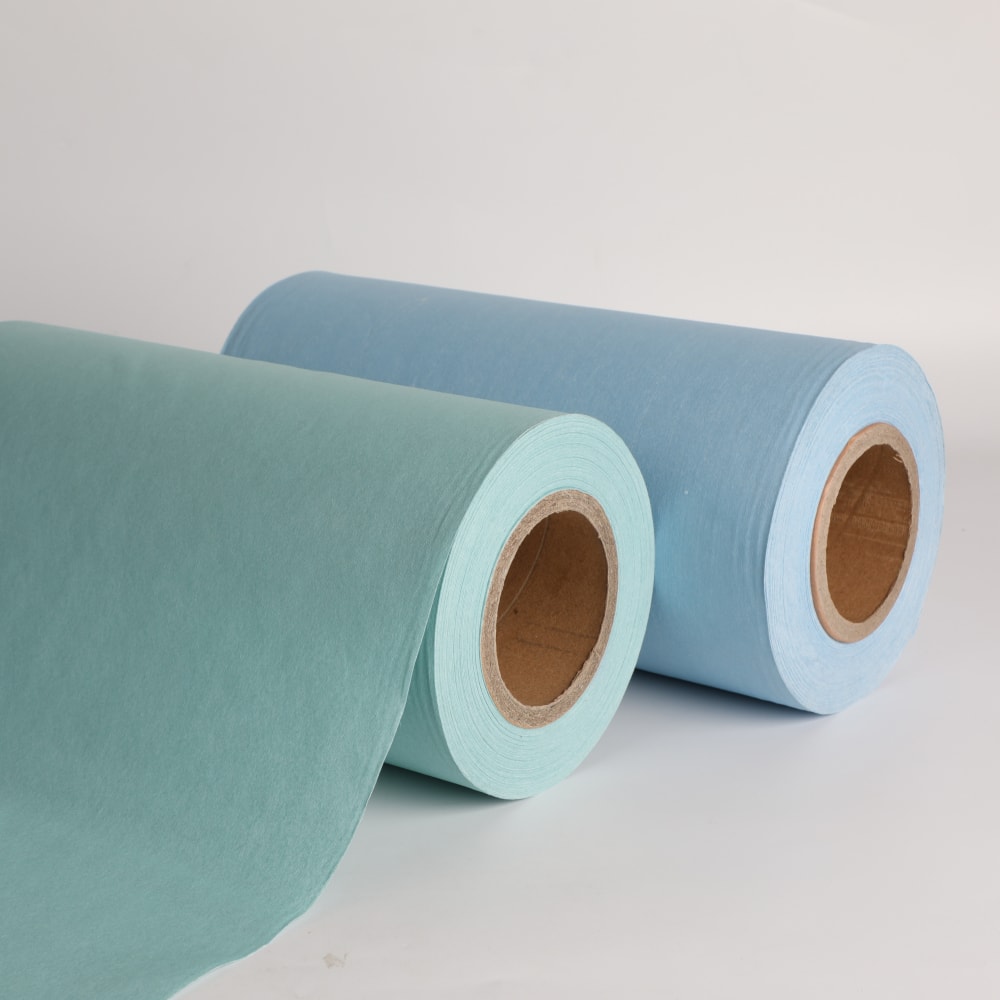

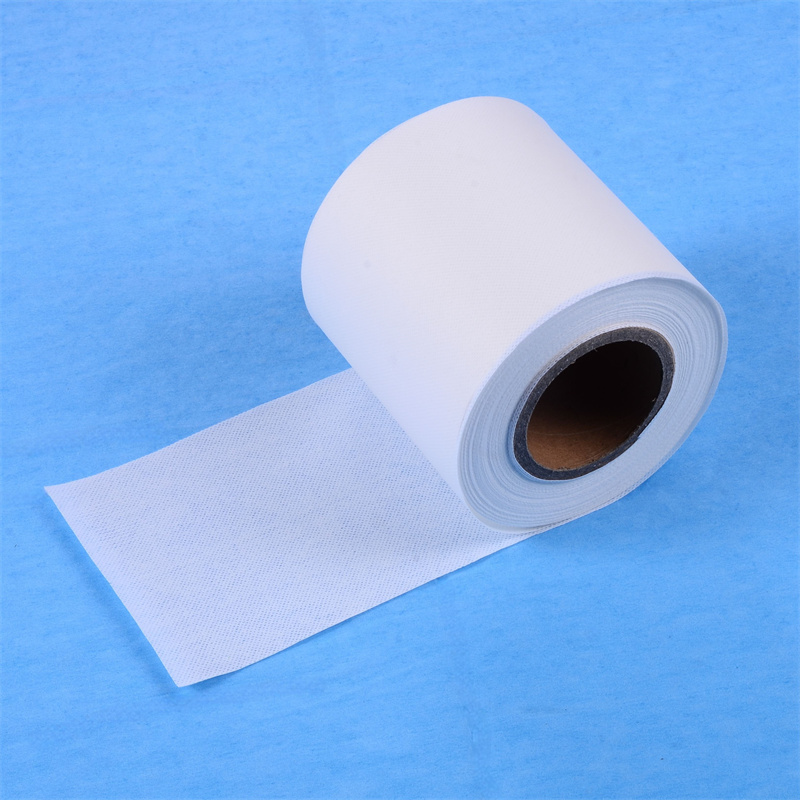

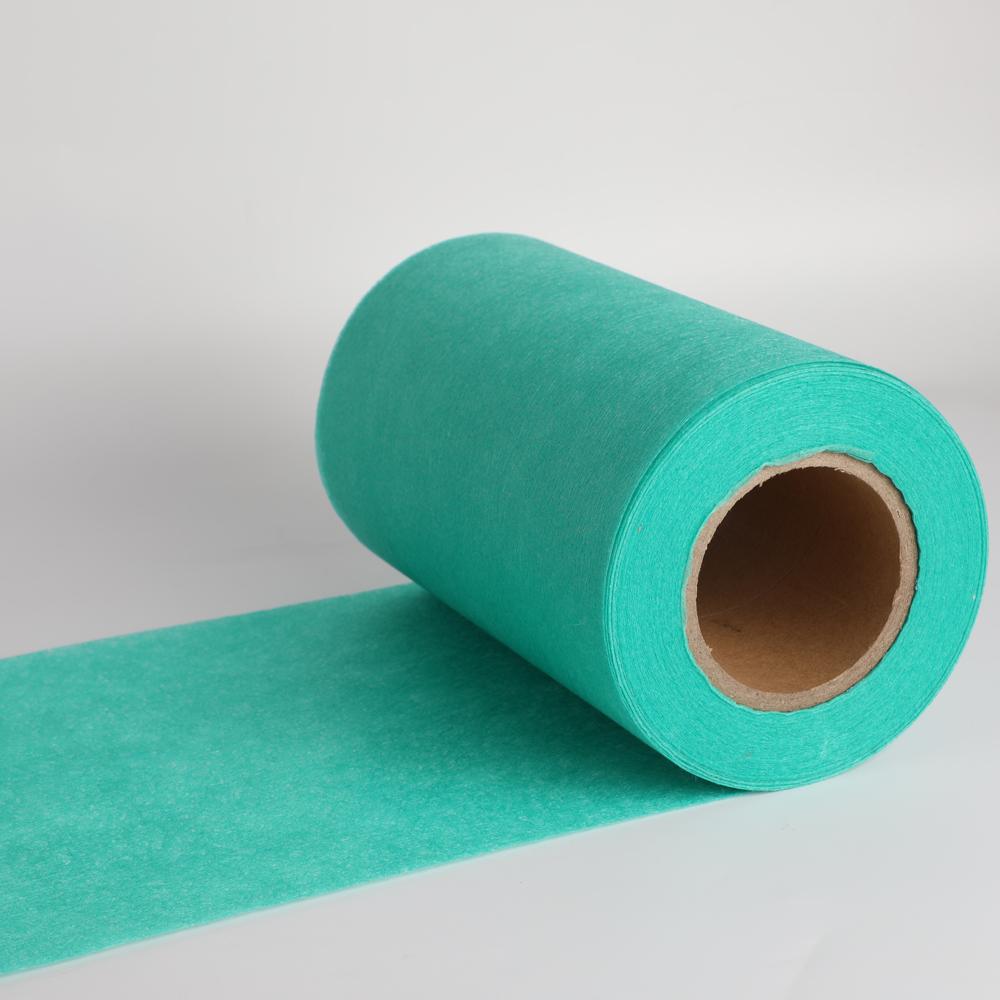

| Color(s) | Blue,White,Yellow |

| Weight | Over 35G |

| Material | Polypropylene |

| Shelf Life | 365 Days |

| Packing | PE wrapping |

Exceptional Hydrophilicity: Our fabric has been specially designed to have outstanding water - absorbing properties. This hydrophilic nature is crucial in medical applications, ensuring efficient liquid management.

High - Quality PP Raw Materials: We source only the finest PP (Polypropylene) raw materials. This guarantees not only the quality of the final product but also its reliability and safety for medical use.

Superior Strength: With excellent tensile strength, the fabric can withstand various handling and processing procedures without tearing or losing its structural integrity.

Product Details

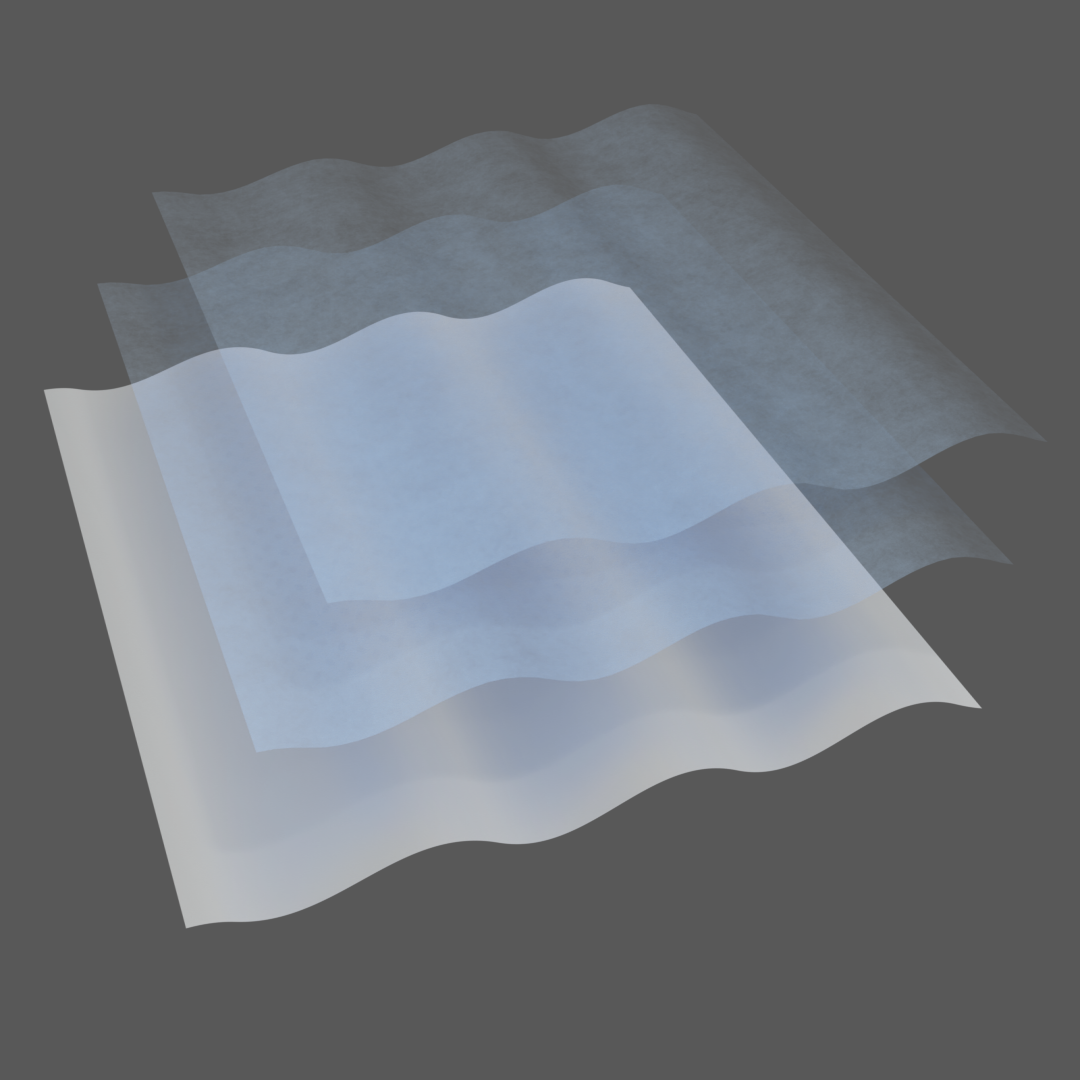

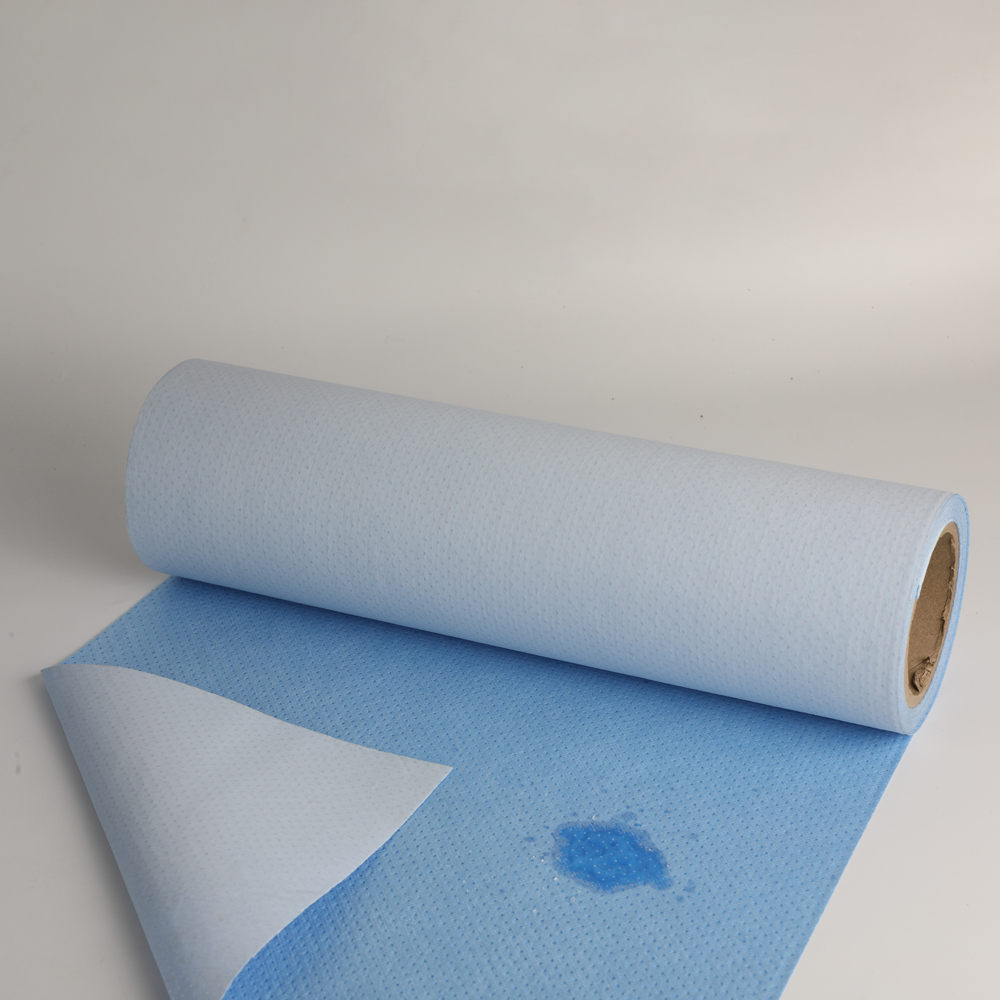

Hydrophilicity: A Key Advantage in Medical Applications

In medical surgical procedures, the ability to handle fluids is of utmost importance. Our Hydrophilic PP laminates nonwoven fabric is designed to quickly absorb and retain liquids. This is especially beneficial in surgical drapes and gowns, where it can prevent the spread of bodily fluids, reducing the risk of cross - contamination. In wound dressings, its hydrophilic nature helps in keeping the wound area moist, which is conducive to the natural healing process. By maintaining an optimal moisture balance, it can also prevent the dressing from sticking to the wound, minimizing pain during dressing changes.

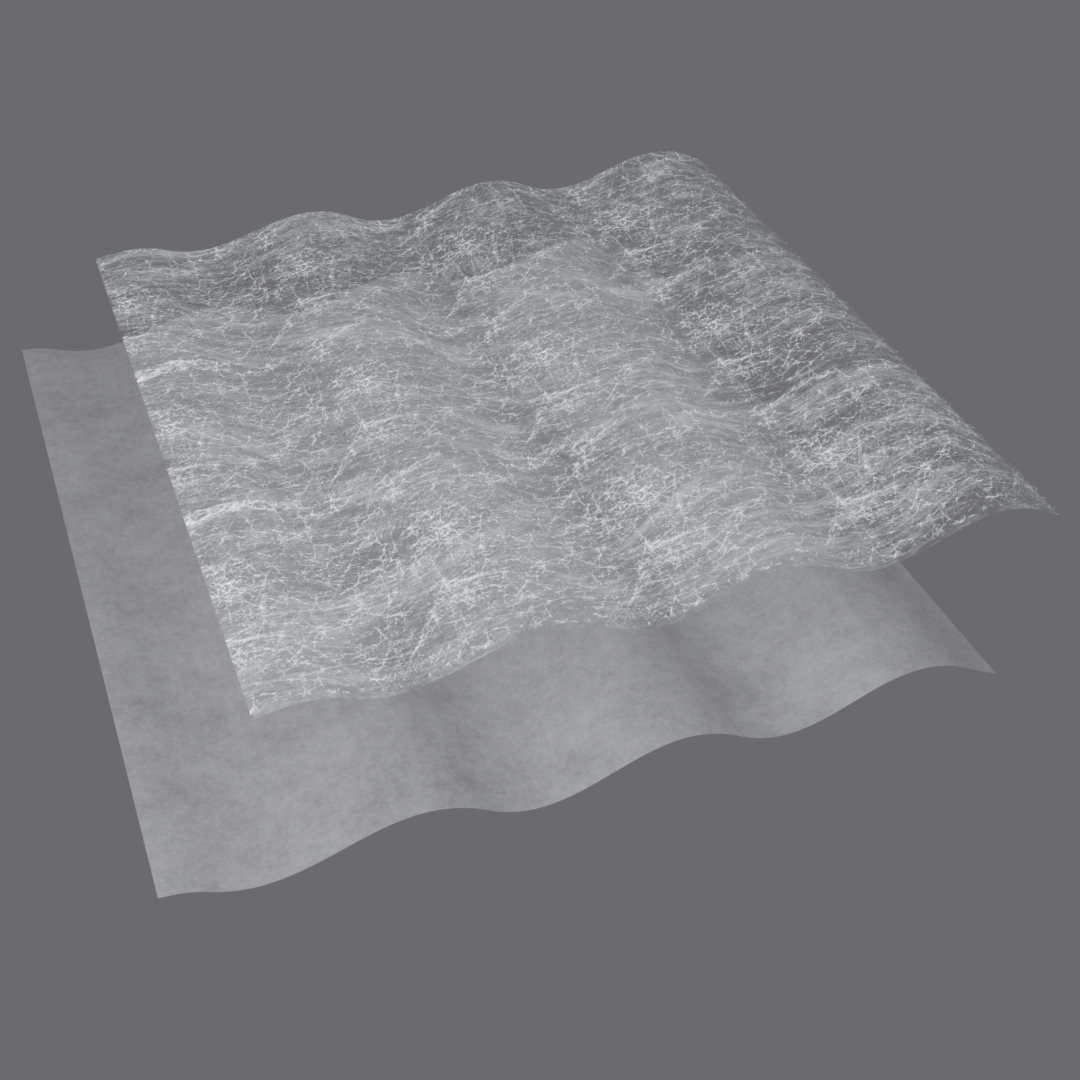

Premium PP Raw Materials Ensure Quality and Safety

The quality of any product starts with its raw materials. We use only the highest - grade PP raw materials in the production of our Hydrophilic PP Laminates Nonwoven Fabric. Polypropylene is known for its chemical resistance, lightweight nature, and non - toxicity, making it an ideal choice for medical applications. The use of top - notch raw materials ensures that our fabric meets the strictest quality and safety standards in the medical industry. It is free from harmful substances and contaminants, providing healthcare professionals and patients with peace of mind.

Strength for Durability and Reliability

Medical surgical consumables often need to endure various mechanical stresses during use. Our fabric's superior strength addresses this need. Whether it's being stretched during the manufacturing of surgical masks or undergoing repeated handling in the operating room, the fabric remains intact. This strength also contributes to the longevity of the medical products made from it. For example, surgical bags made from our fabric can hold heavy medical waste without breaking, and surgical tapes can maintain their adhesion and integrity throughout the surgical procedure.

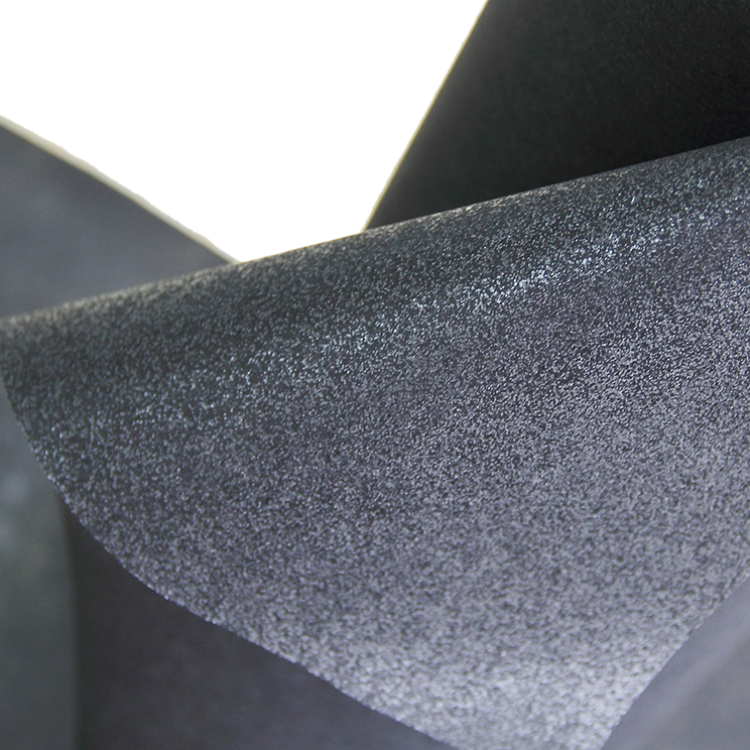

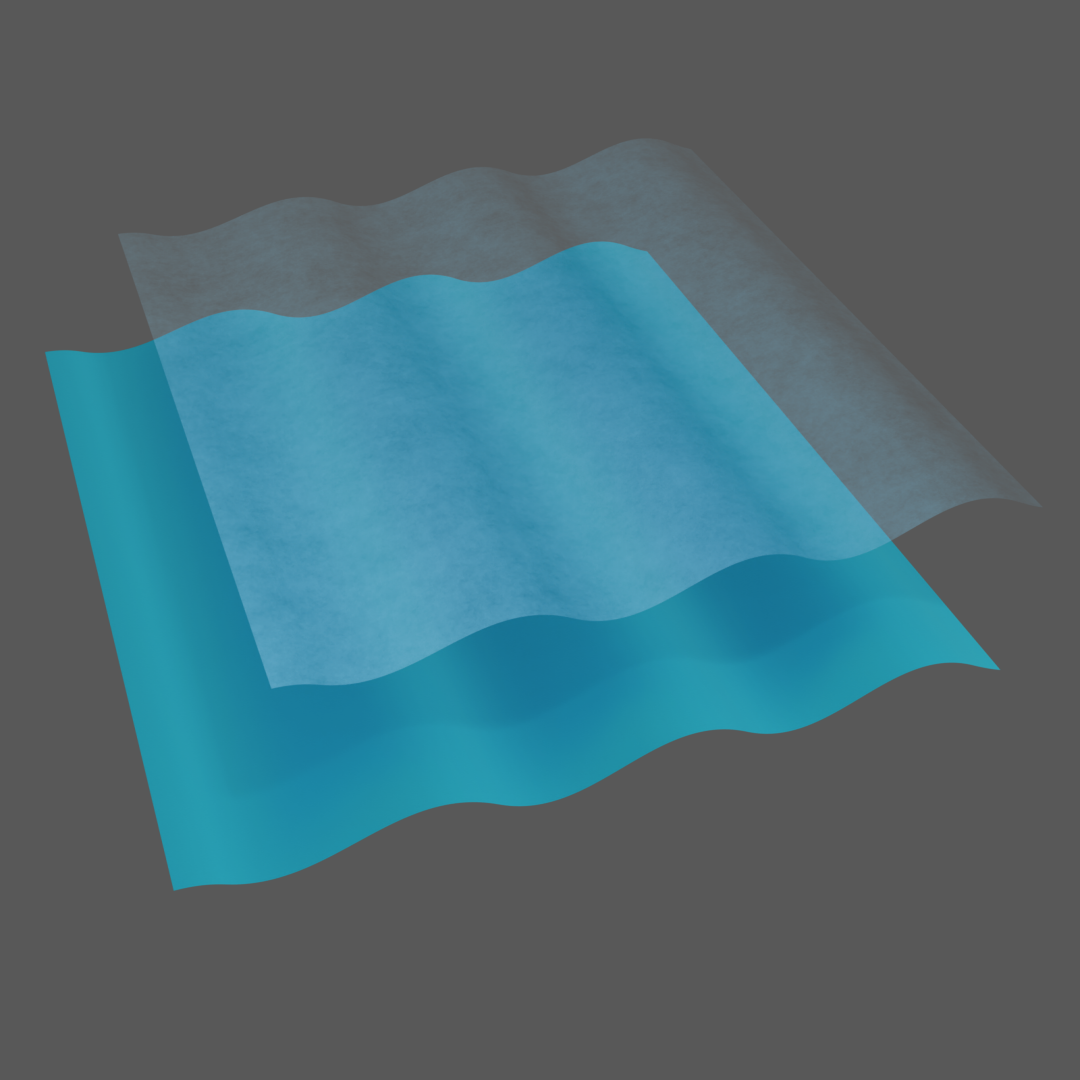

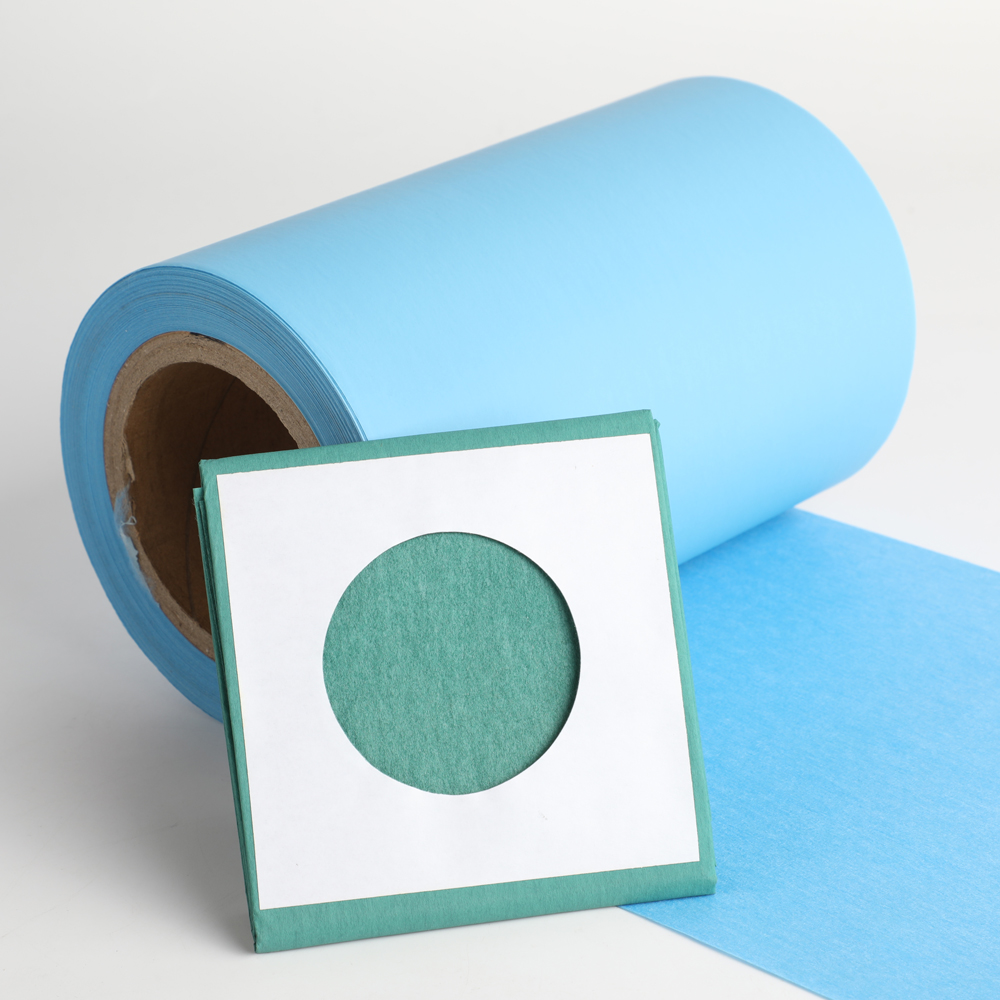

Multi Laminates

Multi Laminates Spunlace Nonwoven Laminates

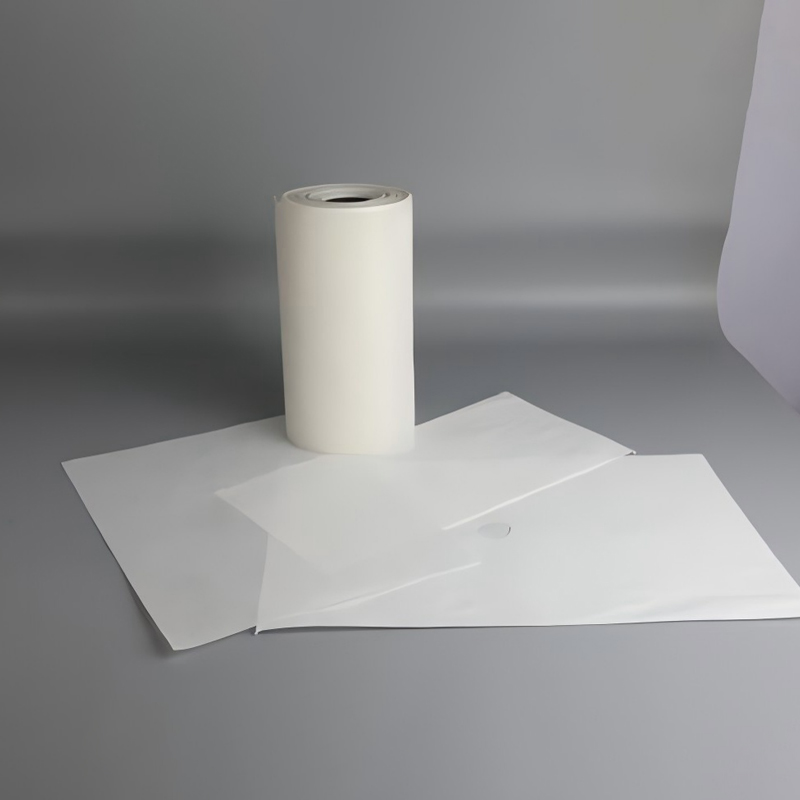

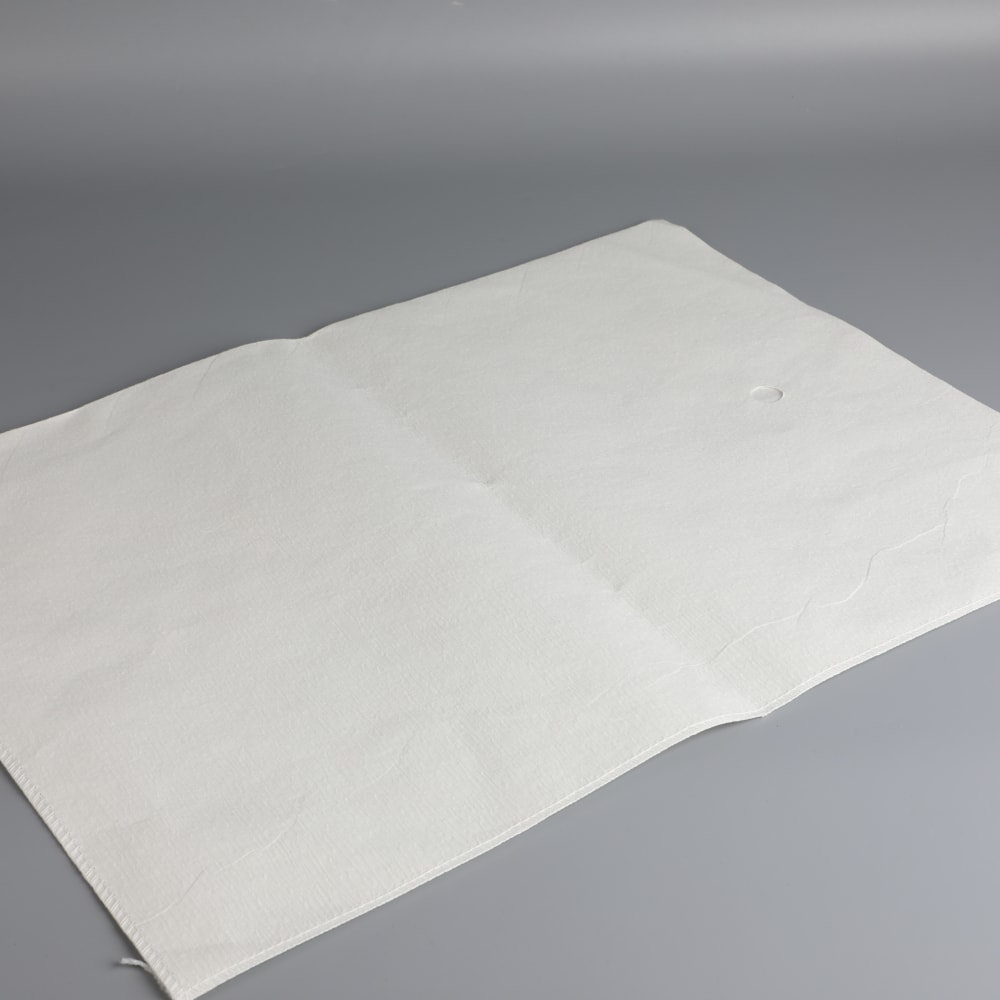

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

Air Filter Media Liquid Filter Media

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

Breathable Film Laminates Nonwoven Interlining

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

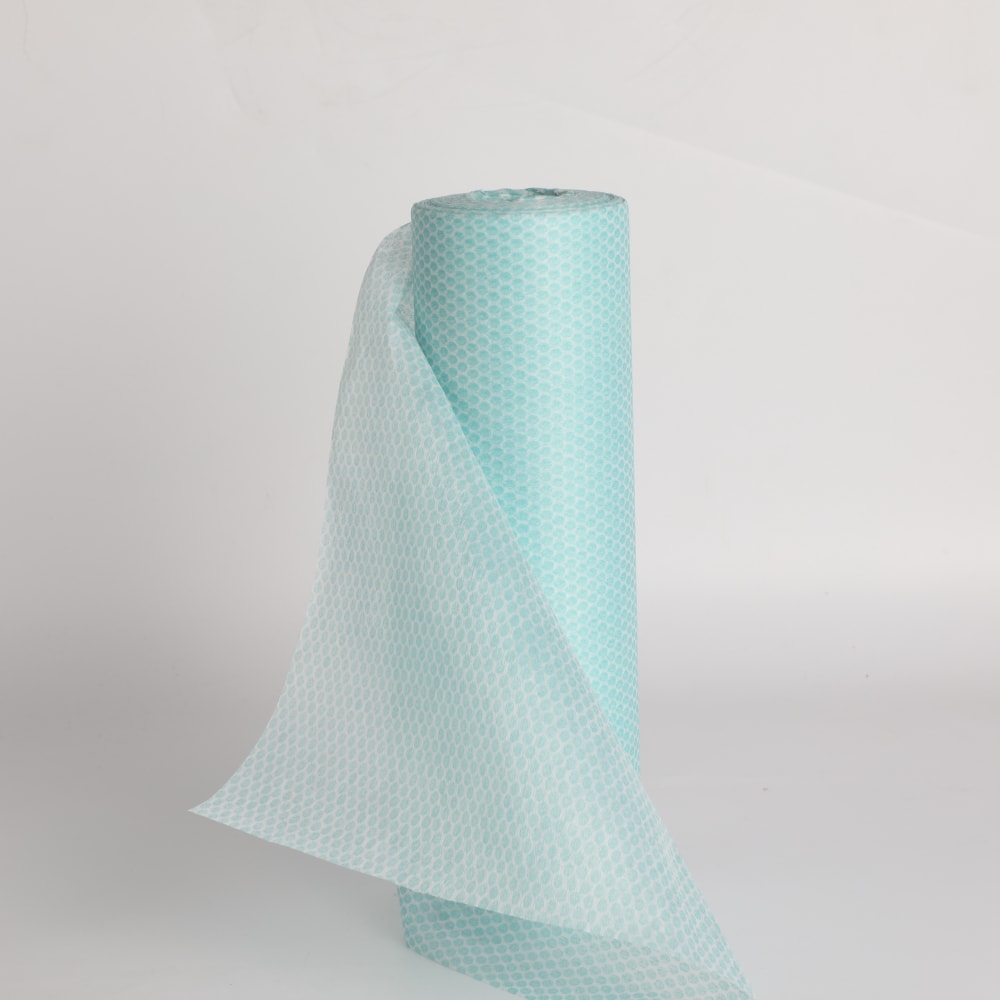

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven