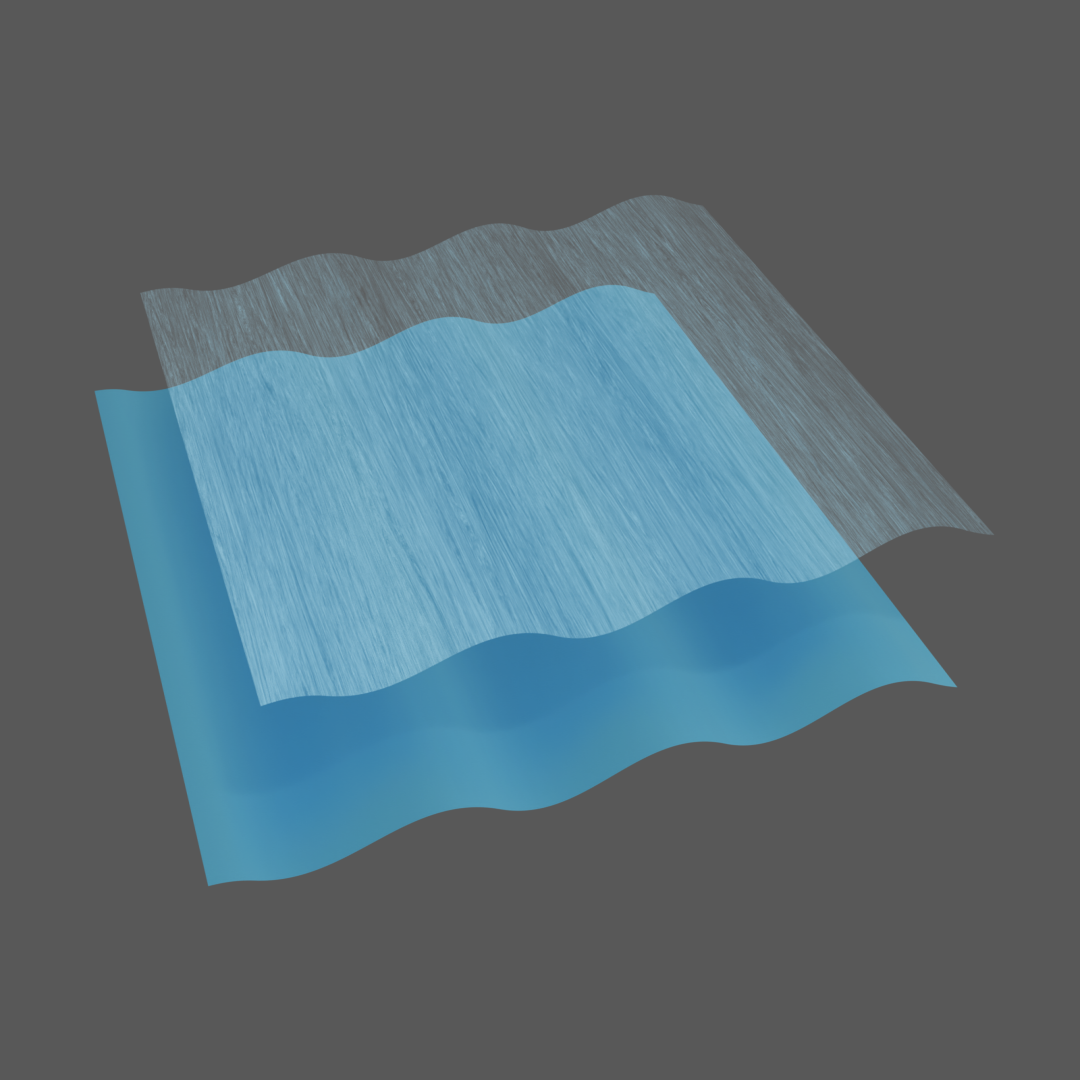

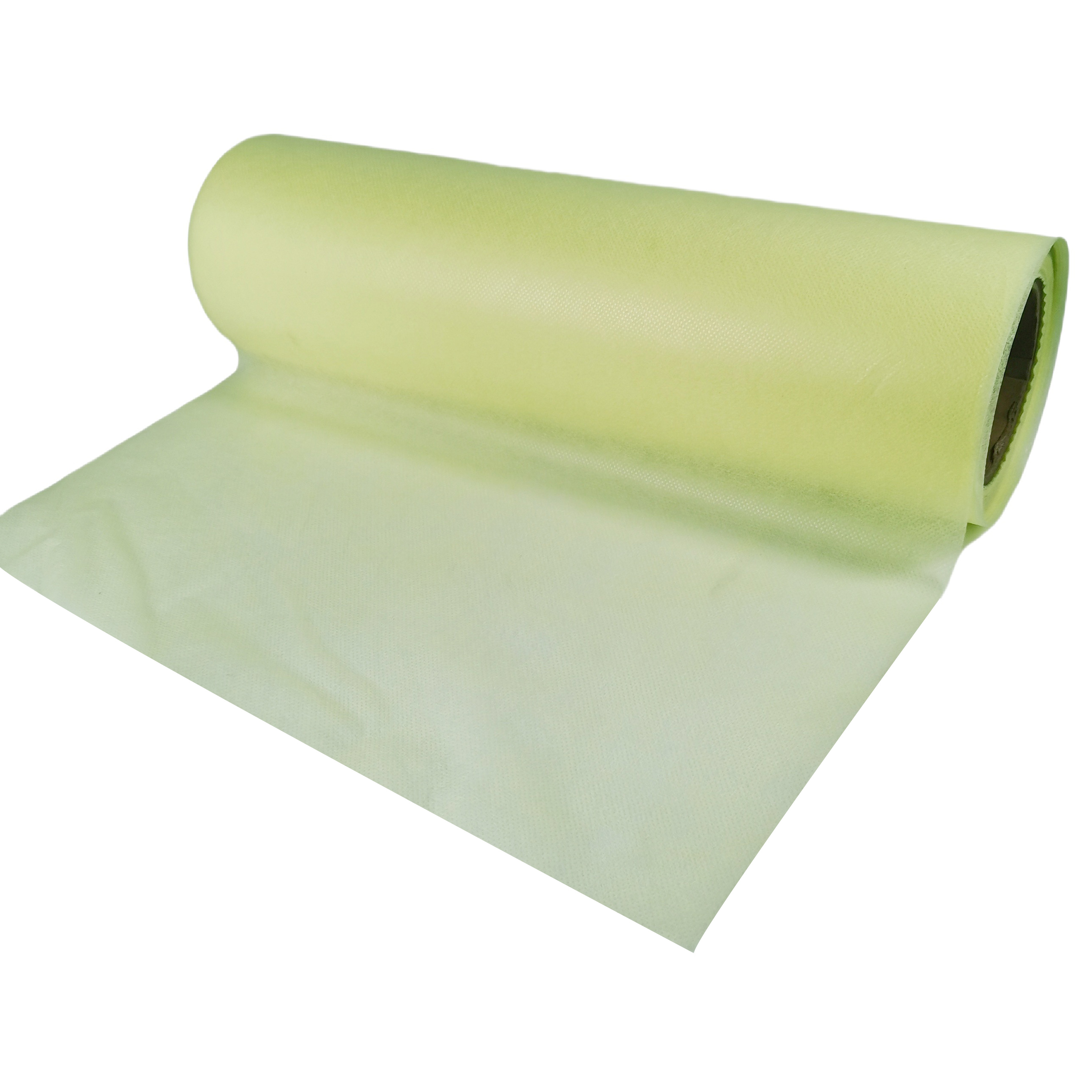

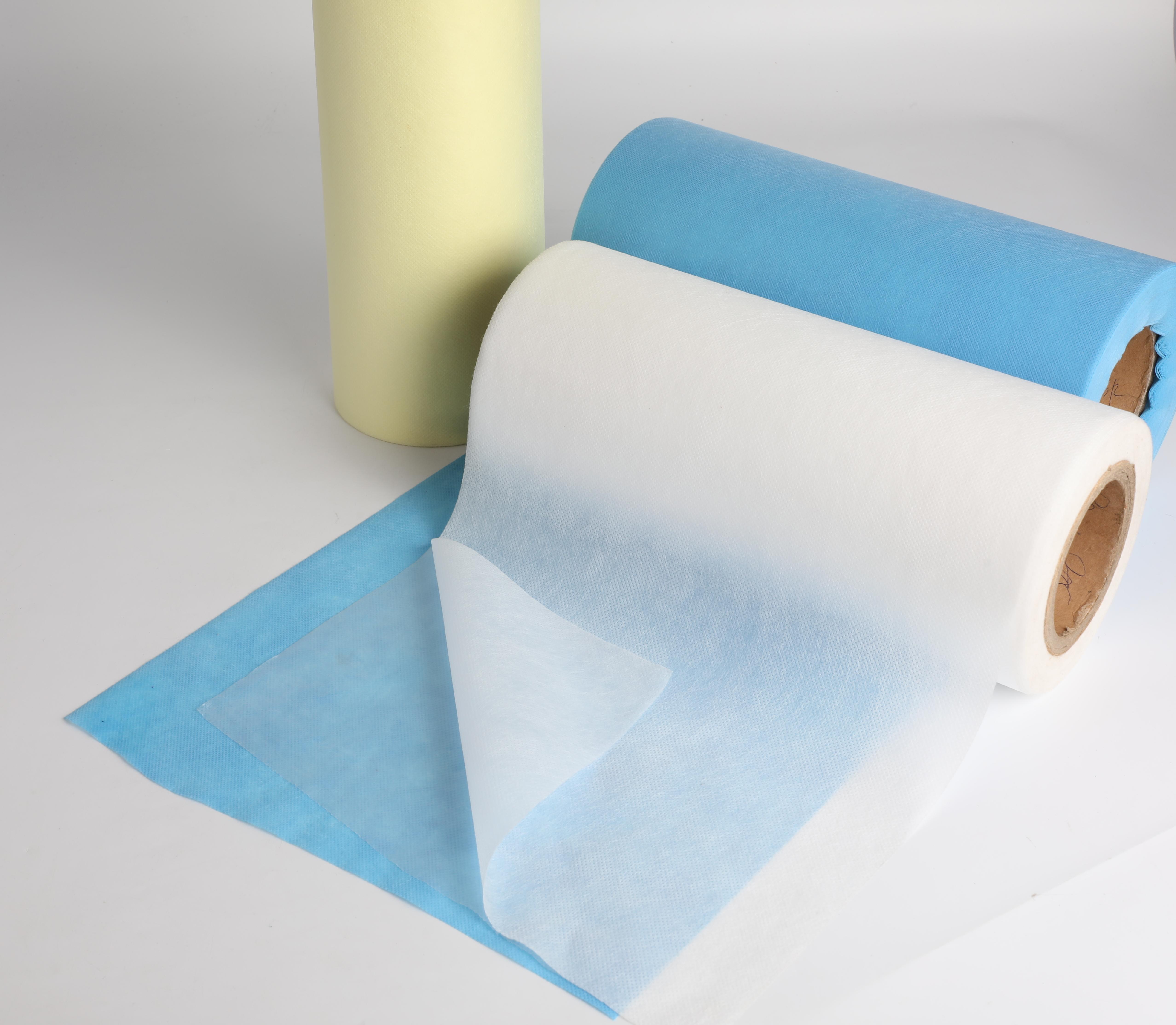

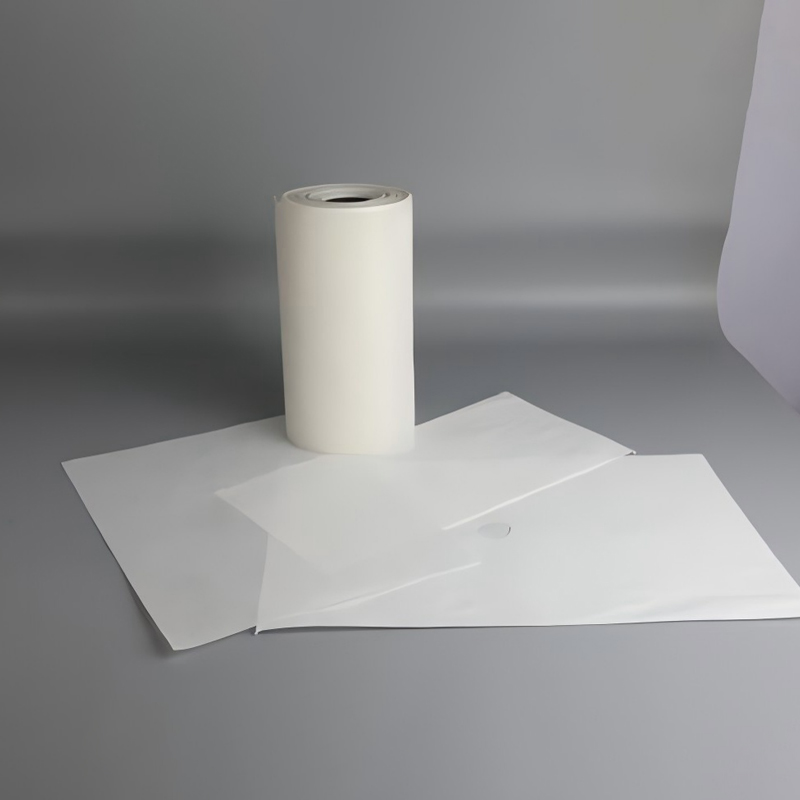

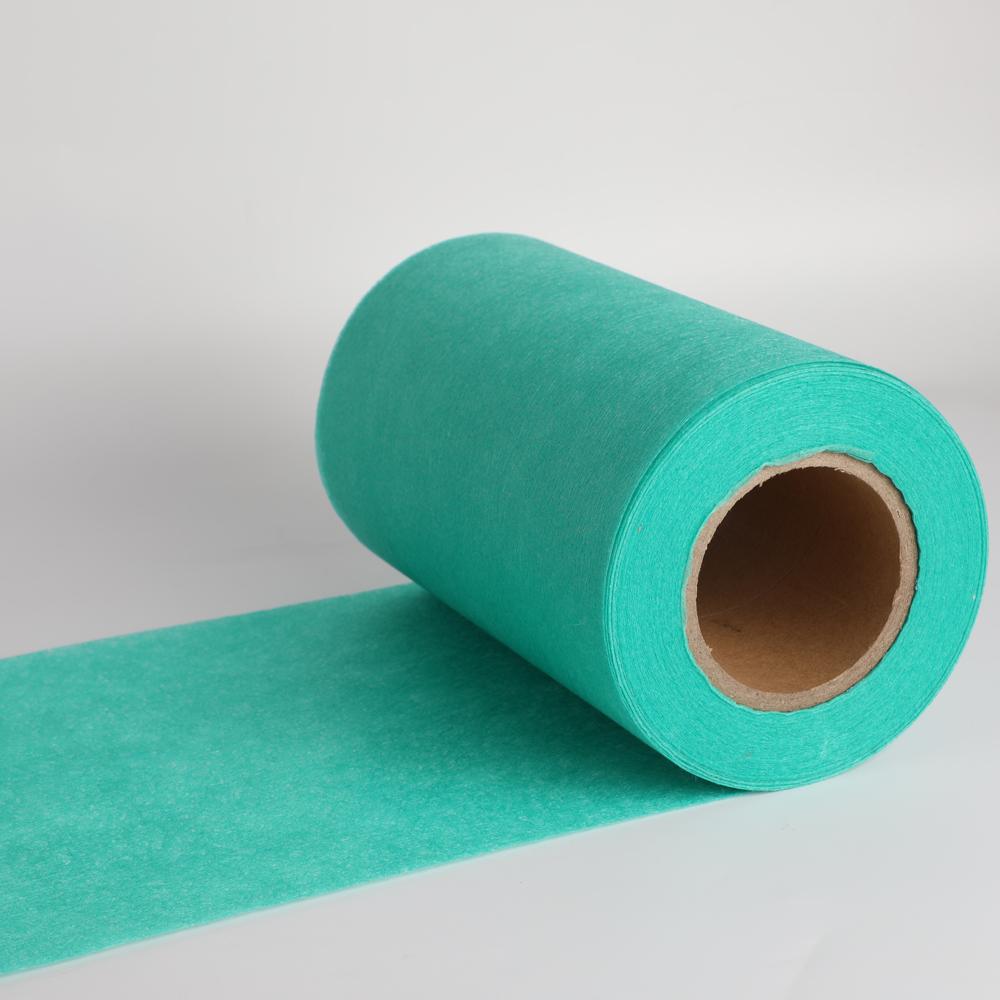

Hotmelt Laminated Breathable Film Nonwoven Fabric

Product Information

| Item | Breathable Film Laminates |

| Manufacturing Technology | Hotmelt laminated |

| Width | Under 240 cm |

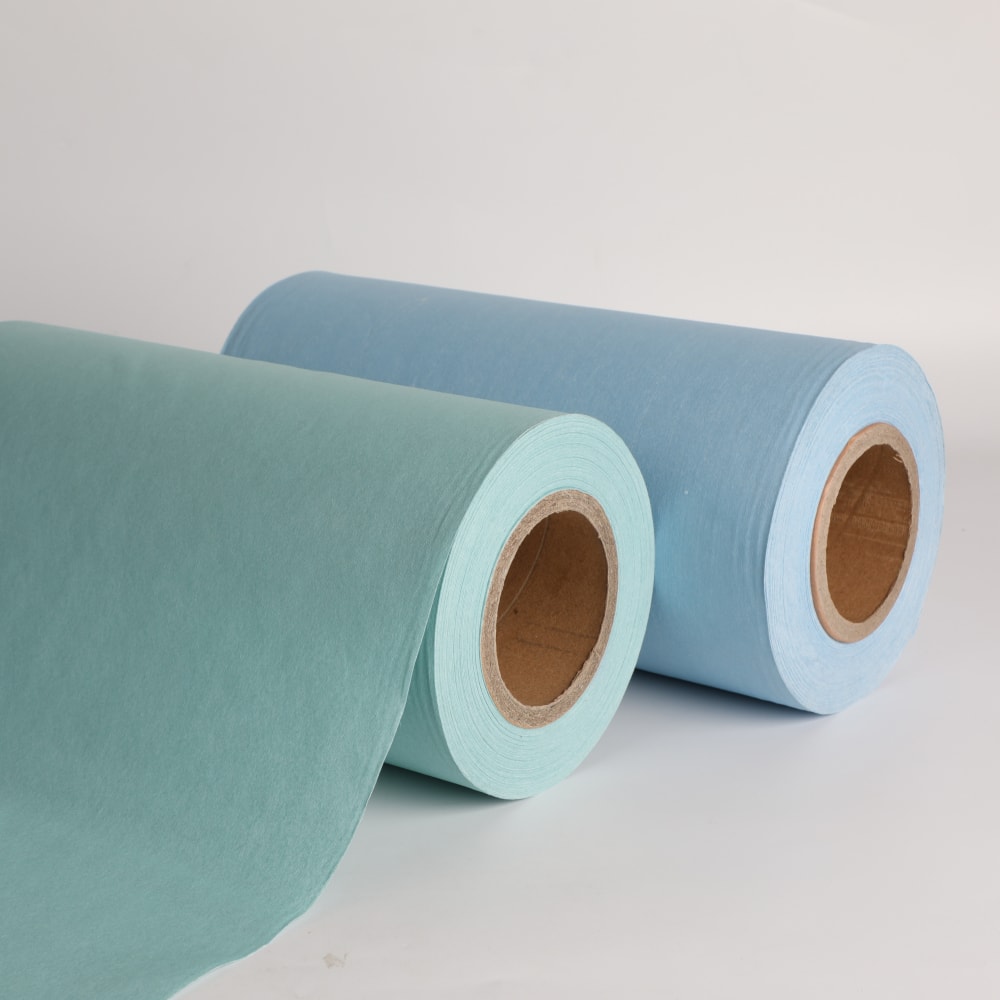

| Color(s) | Blue , White , Yellow |

| Weight | Over 45G |

| Material | PE film |

| Shelf Life | 365 Days |

| Packing | PE wrapping |

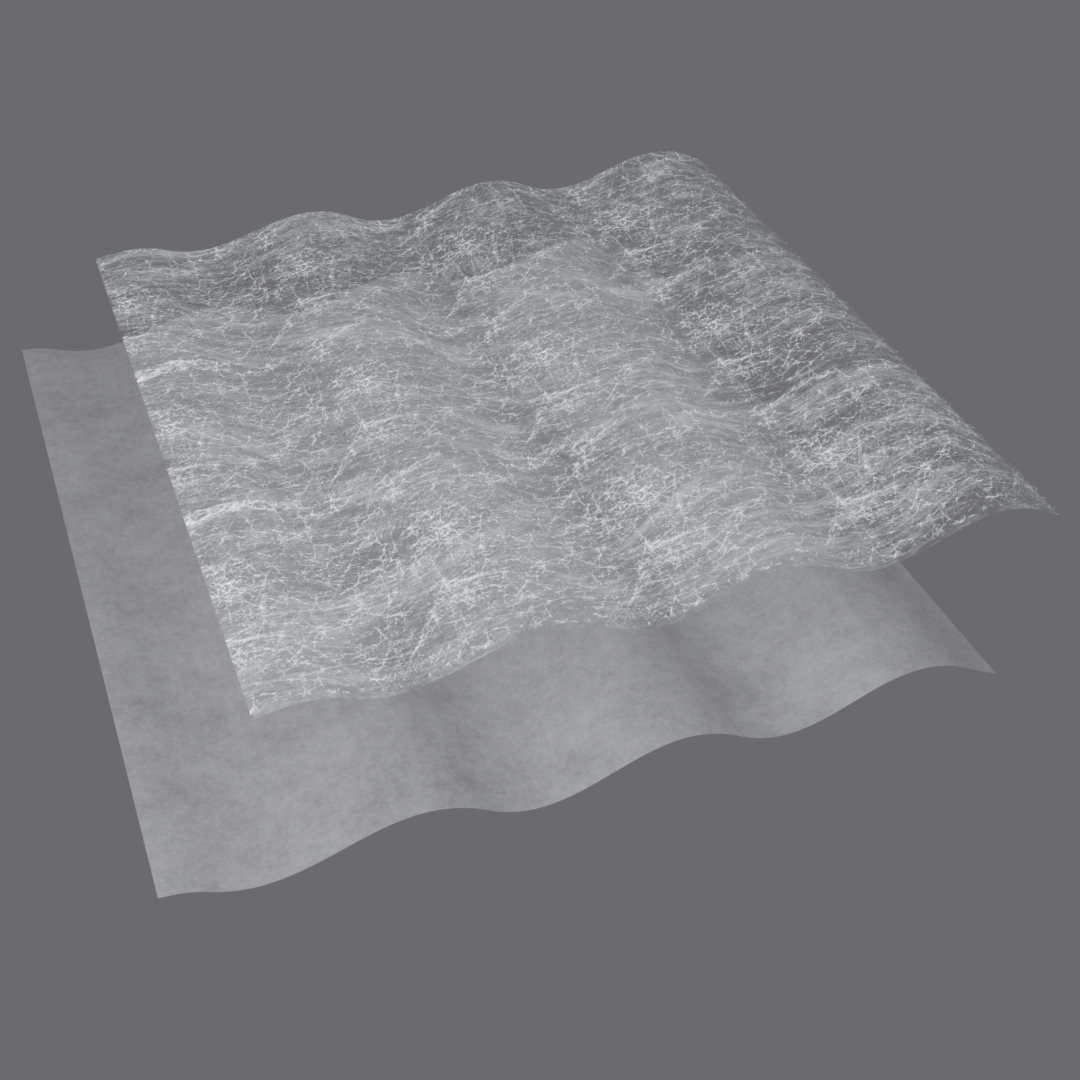

Superior Barrier Against Penetration: Forms a reliable shield, preventing the passage of liquids, bacteria, and other contaminants.

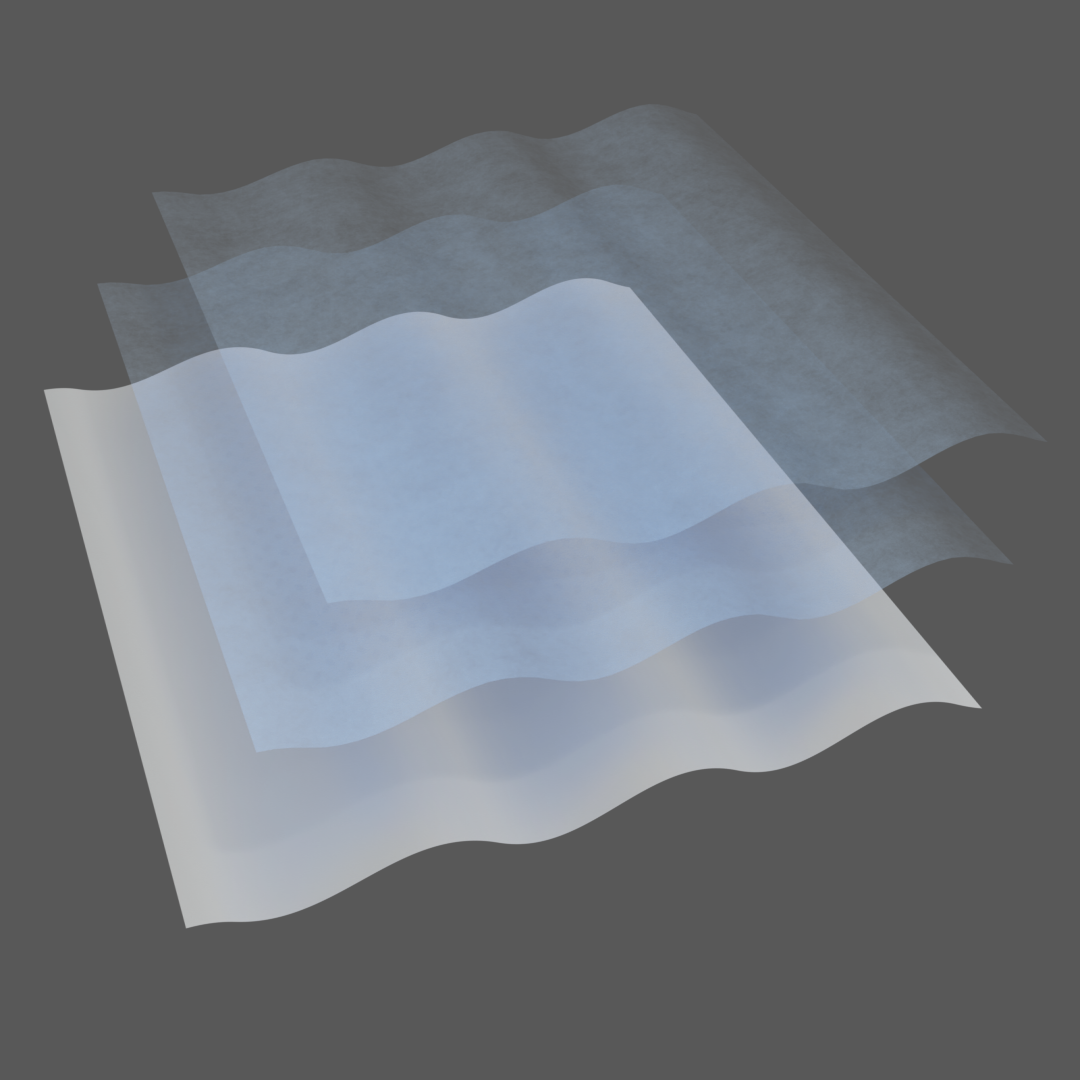

Optimal Breathability: Enables air to flow freely, ensuring comfort for users, whether patients or medical staff.

Ultra-lightweight and Soft: Gentle on the skin, providing a pleasant touch and minimizing any discomfort or chafing.

Product Features

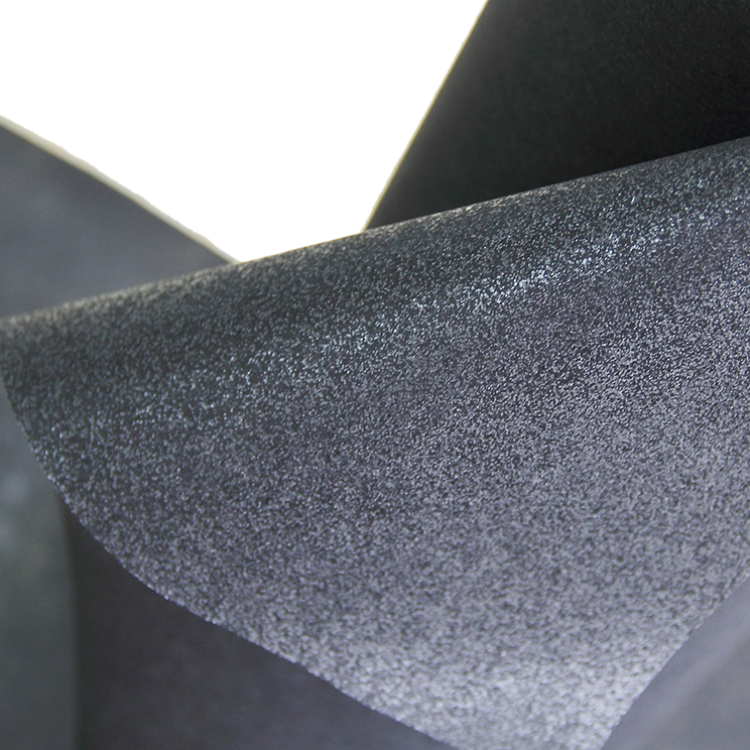

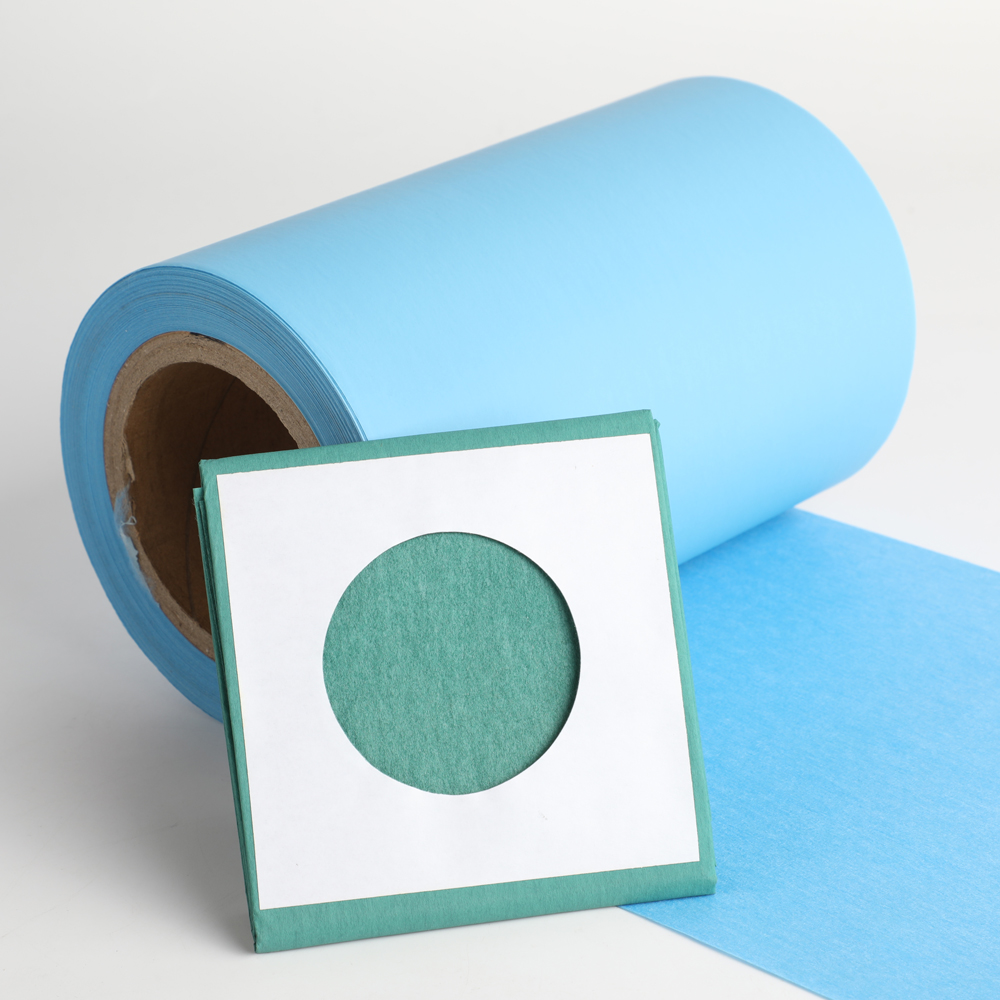

Material Composition and Manufacturing Process

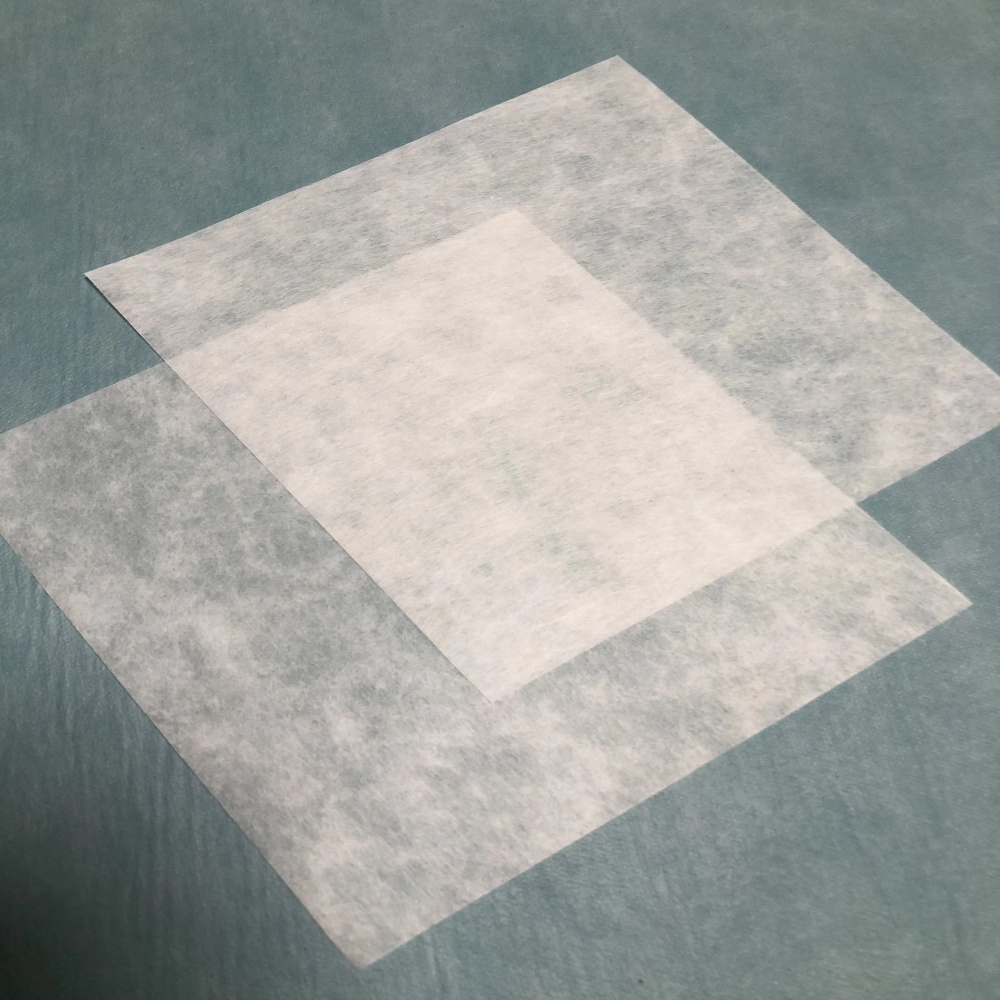

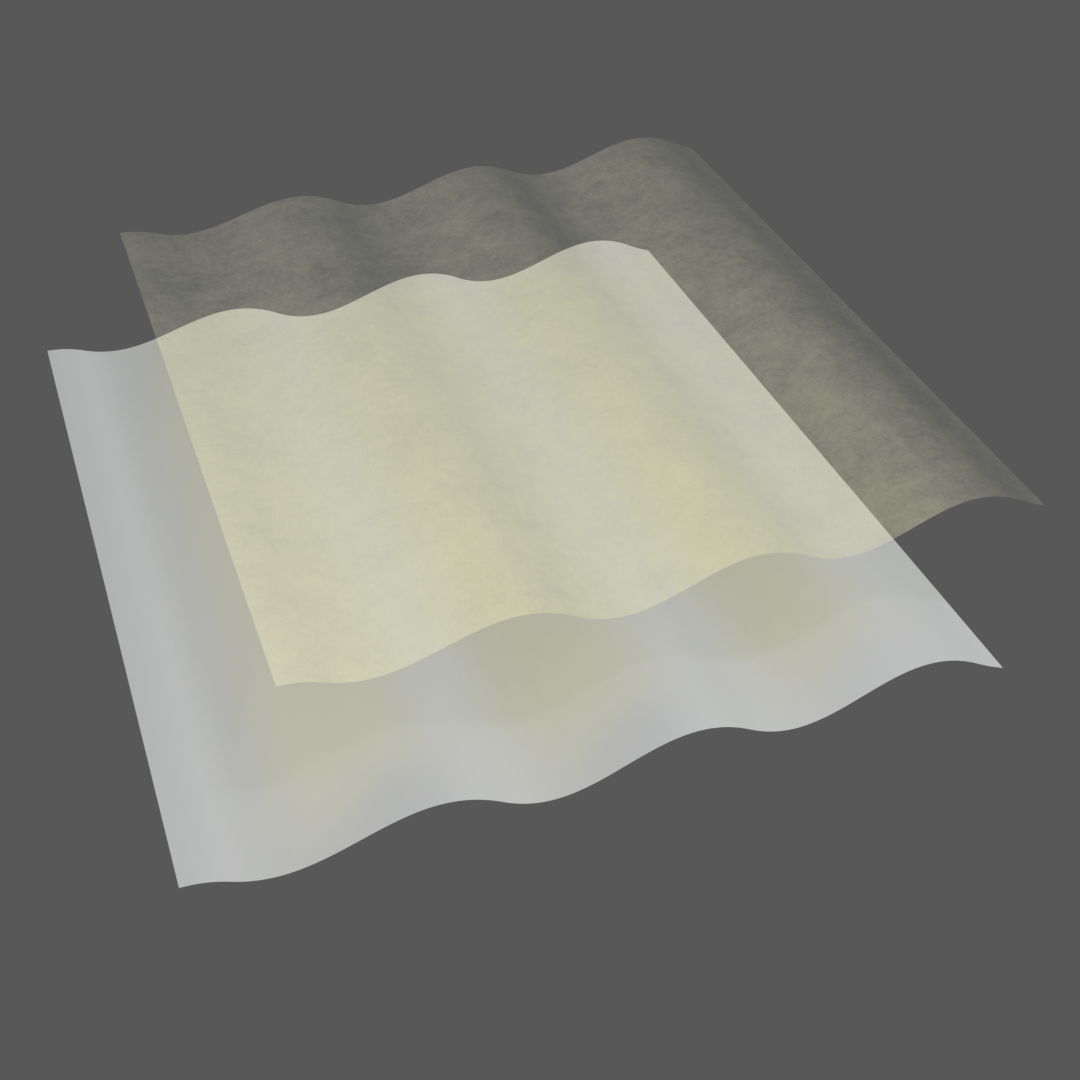

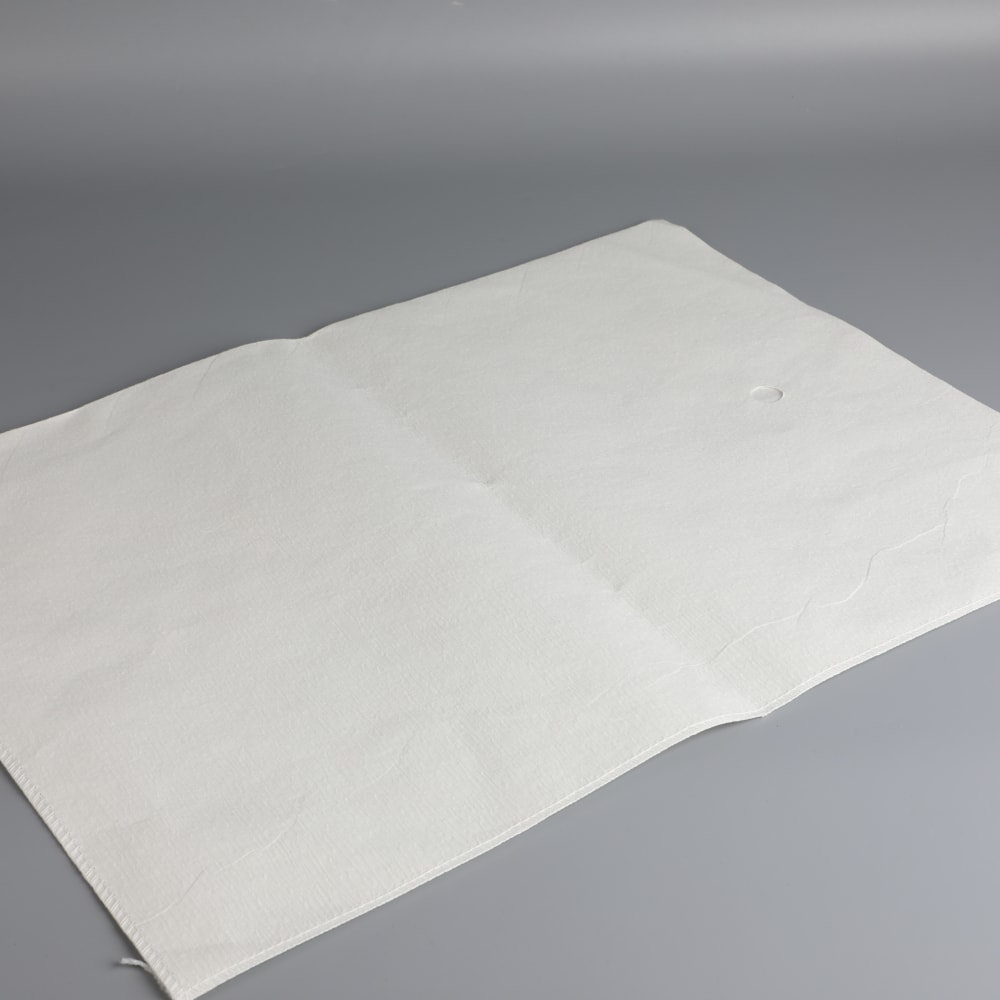

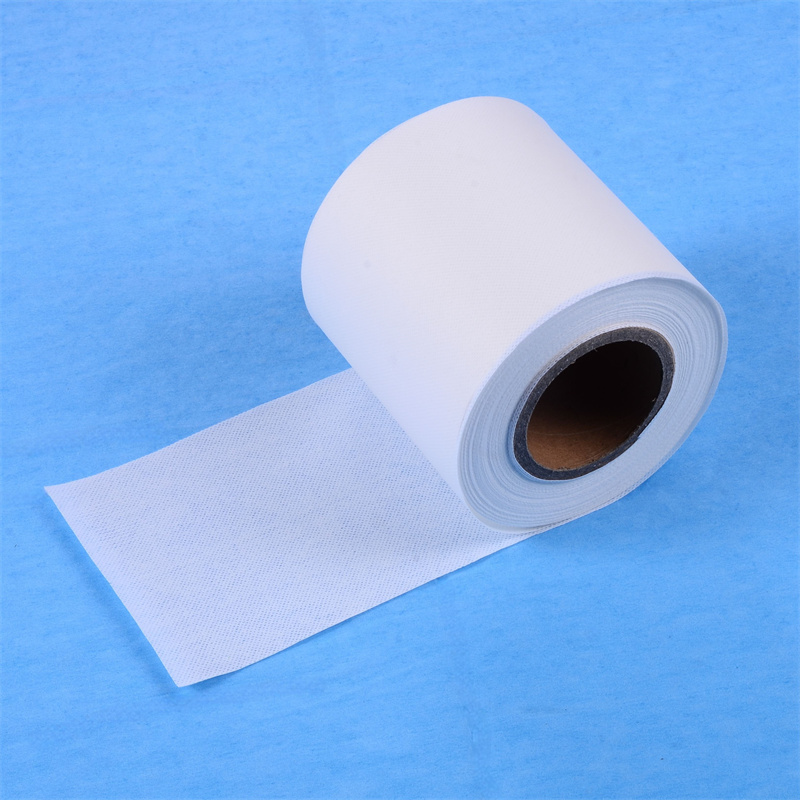

Our hotmelt laminated breathable film nonwoven is the result of advanced manufacturing techniques in our production facility. The base material, the breathable film , is carefully selected for its unique microstructure. It consists of a network of fine fibers that create tiny pores, allowing for excellent air permeability. During the lamination process, we use high-quality hotmelt adhesive. This adhesive not only bonds the layers together securely but also does so without clogging the pores, thus preserving the fabric's breathability. The end product is a composite material with enhanced strength and functionality.

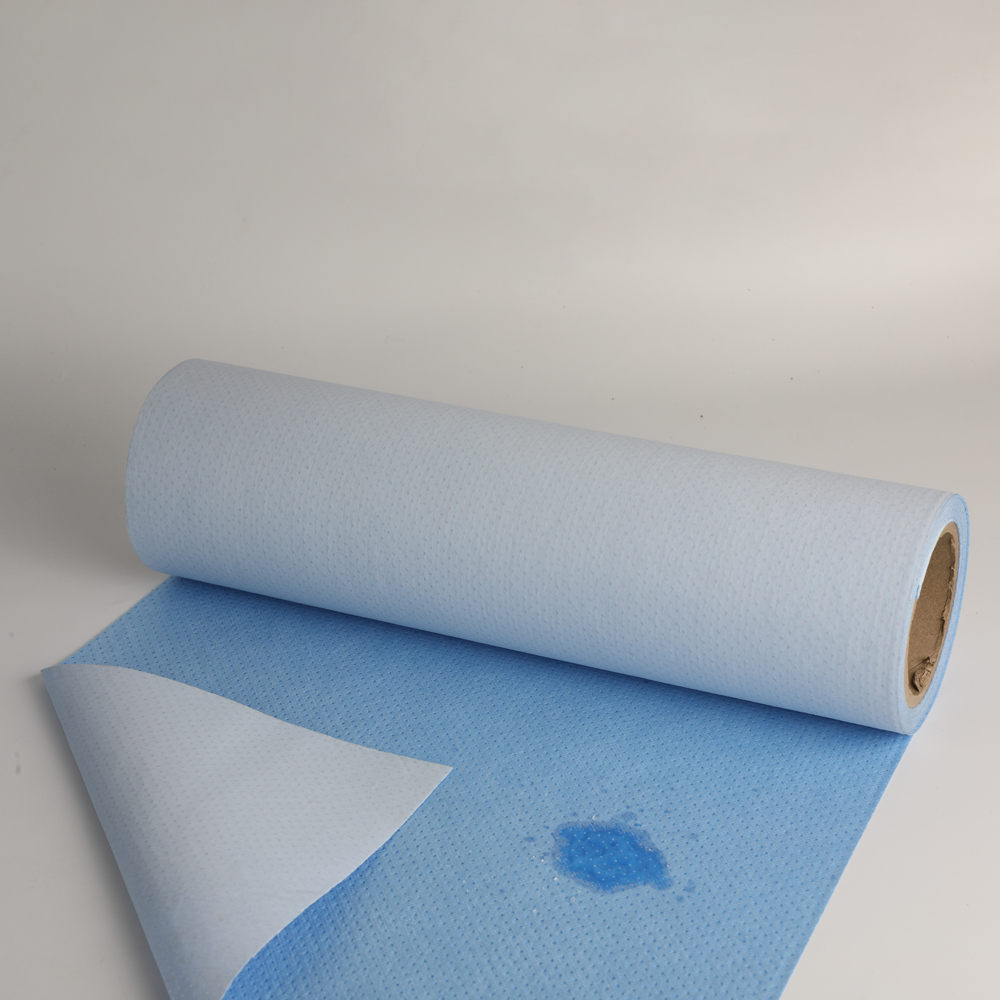

Anti-permeability Feature

In the medical field, preventing the infiltration of substances is crucial. Our product's anti-permeability property is outstanding. It can effectively resist the penetration of bodily fluids such as blood, sweat, and other exudates. This is vital for applications like surgical drapes and wound dressings. For instance, in a surgical setting, a single drop of liquid penetrating the drape could potentially contaminate the sterile field, leading to serious consequences. Our nonwoven material provides a watertight yet breathable barrier, ensuring the highest standards of safety and hygiene.

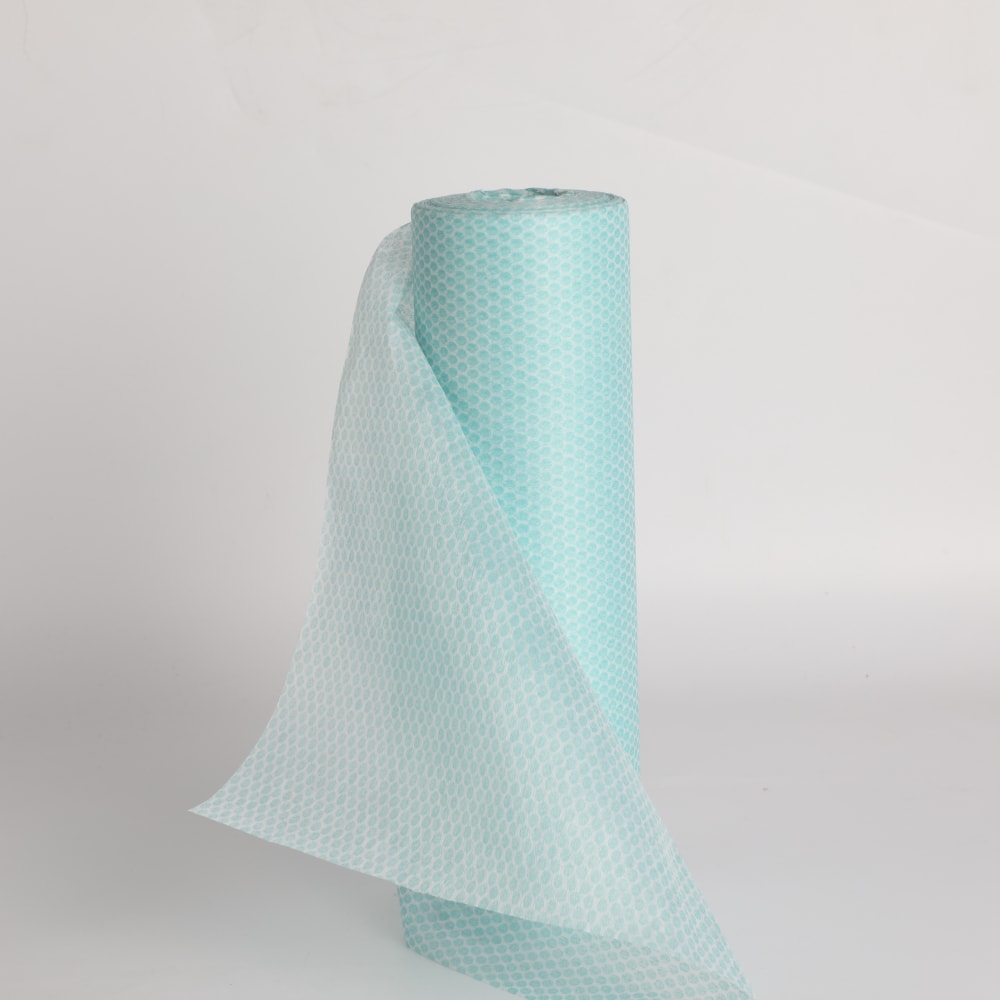

Comfort and Breathability Benefits

Comfort plays a significant role in medical applications. The breathable nature of our fabric allows for constant air circulation, preventing overheating and discomfort. This is especially important for patients who may be bedridden or wearing medical devices for extended periods. The lightweight and soft texture add to the comfort quotient. It feels gentle against the skin, reducing the risk of skin irritation or pressure sores. Medical staff also appreciate these qualities when wearing protective gear during long shifts.

Applications in Medical Consumables Industry

This material has a unique application in the field of medical consumables. It is the main material of protective clothing, escort for doctors , laboratory personnel and so on, protect against virus infection, and play a role in barrier protection and protection. The material is breathable to provide the user with a comfortable and soft experience to the maximum extent possible, while allowing the user to breathe easily and provide efficient protection.

Multi Laminates

Multi Laminates Spunlace Nonwoven Laminates

Spunlace Nonwoven Laminates Breathable Film Laminates

Breathable Film Laminates Viscose Laminates

Viscose Laminates Medical Tape Nonwoven

Medical Tape Nonwoven Filtration Nonwoven

Filtration Nonwoven Head Wear Nonwoven

Head Wear Nonwoven Medical Viscose Nonwoven

Medical Viscose Nonwoven Air Filter Media

Air Filter Media Liquid Filter Media

Liquid Filter Media Filter Envelope & Filter Sheet

Filter Envelope & Filter Sheet Breathable Film Laminates

Breathable Film Laminates Nonwoven Interlining

Nonwoven Interlining Fluid Repellent Woodpulp Spunlace Nonwoven

Fluid Repellent Woodpulp Spunlace Nonwoven Woodpulp Nonwoven Wipe

Woodpulp Nonwoven Wipe Nonwoven Cleaning Wipe

Nonwoven Cleaning Wipe Flame Retardant Nonwoven Fabric

Flame Retardant Nonwoven Fabric Anti-Bacterial Nonwoven

Anti-Bacterial Nonwoven