Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

The market for water repellent nonwoven materials is experiencing significant growth, driven by advancements in textile technology and an increasing demand across various industries. According to a report by Grand View Research, the global nonwoven fabric market size was valued at USD 45.47 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 8.4% from 2021 to 2028. Water repellent nonwoven materials, a subset of this market, play a critical role in sectors including healthcare, automotive, and construction, owing to their unique properties that enhance durability and performance.

One of the primary applications of water repellent nonwoven materials is in hygiene and medical products, where moisture management is crucial for patient comfort and product efficacy. In addition, the automotive and industrial segments are increasingly utilizing these materials for their ability to provide protective barriers against environmental factors. Furthermore, the rising focus on sustainable and eco-friendly materials has led to the development of innovative processes that enhance the water-repellent capabilities of nonwoven fabrics while minimizing environmental impact.

As we look towards 2025, the importance of water repellent nonwoven materials cannot be overstated. Their versatility and effectiveness in a variety of applications highlight their vital role in meeting current and future market demands. Emphasizing these benefits, industry stakeholders are poised to capitalize on this growing trend, positioning water repellent nonwoven materials at the forefront of technological development and market expansion.

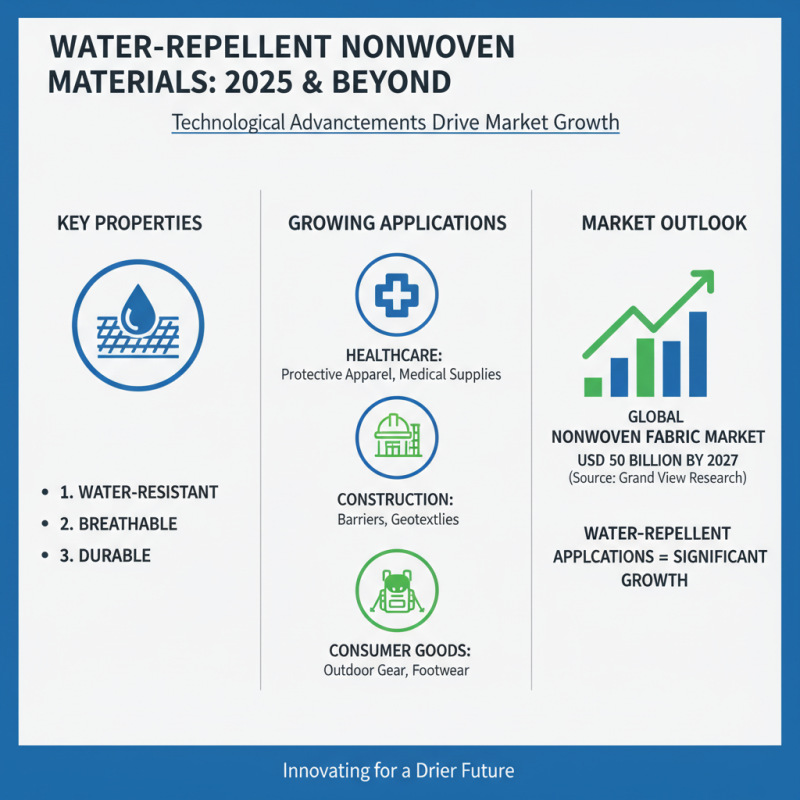

In 2025, the landscape of water repellent nonwoven materials continues to evolve, driven by advancements in technology and growing demand across various industries. These materials, recognized for their unique properties, are increasingly being utilized in sectors such as healthcare, construction, and consumer goods. According to a market report by Grand View Research, the global nonwoven fabric market is expected to reach USD 50 billion by 2027, with water repellent applications contributing significantly to this growth. The enhanced ability of these materials to resist water while remaining breathable makes them ideal for use in protective clothing, disposable medical supplies, and even outdoor gear.

The benefits of integrating water repellent nonwoven materials extend beyond just durability. They offer improved comfort and usability for end-users. A study published in the Journal of Textile Science highlights that these fabrics maintain their performance in various conditions, making them suitable for both indoor and outdoor applications. Moreover, their lightweight nature and ease of manufacturing align well with sustainability goals, as many nonwoven fabrics can be produced from recycled materials and are designed for easy disposal.

**Tip 1:** When selecting water repellent nonwoven materials for a specific application, assess the environmental impact and choose options that align with sustainability practices.

**Tip 2:** Consider the end-use requirements; for instance, materials intended for medical applications should not only be water repellent but also biocompatible.

By focusing on these critical attributes, manufacturers and consumers can harness the full potential of water repellent nonwoven materials in 2025 and beyond.

Water repellent nonwoven materials have gained significant traction across multiple industries due to their unique properties, which offer enhanced durability and protection. In the medical sector, for example, these materials are utilized in surgical gowns and drapes, where maintaining a sterile environment is paramount. According to a report by Smithers Pira, the global nonwoven medical market was valued at approximately $15 billion in 2022, and water repellent fabrics are expected to drive a substantial portion of this growth, as they help prevent liquid penetration, thereby ensuring the safety and comfort of both patients and healthcare providers.

In the automotive industry, water repellent nonwoven materials are increasingly being adopted in various applications, including insulation and interior fabrics. The growth of the automotive sector has led to a rising demand for lightweight materials that can resist water and moisture, ultimately enhancing vehicle longevity and passenger comfort. A study from the Freedonia Group projects that the global market for automotive nonwovens will reach $8 billion by 2025, with water repellency playing a critical role in material selection for components that encounter environmental exposure.

Furthermore, the outdoor apparel and gear industry also leverages the benefits of water repellent nonwoven materials. With increasing consumer preference for high-performance clothing that withstands varied weather conditions, manufacturers are incorporating these materials into jackets, tents, and footwear. In fact, the global outdoor apparel market is expected to exceed $20 billion by 2025, with water repellent features becoming a key selling point. This trend highlights the rising expectations for functionality and durability in consumer products, positioning water repellent nonwoven materials as essential components across diverse applications.

Water repellent nonwoven materials have emerged as a game-changer in various industries, offering significant advantages for both consumers and manufacturers. For consumers, these materials provide enhanced protection against moisture, making them ideal for a wide range of applications, such as outdoor apparel, home textiles, and personal care products. By keeping water at bay, these nonwoven fabrics help maintain comfort and hygiene, which is especially beneficial in products like diapers and feminine hygiene items. The ease of maintenance and durability of water repellent nonwovens further enhance their appeal, ensuring that consumers receive reliable products that withstand everyday wear and tear.

From a manufacturer's perspective, utilizing water repellent nonwoven materials can lead to increased efficiency and cost-effectiveness. These materials can often be produced in large quantities, allowing for scalable production processes. Additionally, the water repellent feature reduces the need for additional treatments or coatings, streamlining production and lowering costs. This not only enhances the bottom line but also aligns with eco-friendly initiatives, as many modern nonwoven materials are designed to be recyclable or biodegradable. Overall, both consumers and manufacturers stand to benefit greatly from the adoption of water repellent nonwoven technologies, fostering innovation and sustainability in the market.

Technological advancements in the realm of nonwoven materials have significantly enhanced the water repellency of these fabrics, making them increasingly viable for a broad spectrum of applications. The incorporation of innovative finishes and treatments, such as hydrophobic coatings and advanced fiber engineering, has enabled the creation of nonwoven materials that effectively repel water while maintaining breathability. These processes not only optimize the fabric's performance but also improve its overall durability, ensuring that products made from these materials can withstand adverse environmental conditions.

Furthermore, the integration of nanotechnology has played a pivotal role in the evolution of water-repellent nonwoven fabrics. By manipulating materials at the molecular level, manufacturers can develop textiles with exceptional water resistances, such as those that can self-clean or resist staining from liquids. These advancements are driving demand in various industries, from outdoor apparel to medical textiles, where the need for reliable, water-resistant materials is paramount. As research continues to push the boundaries of material science, the benefits of water-repellent nonwoven fabrics are expected to expand, highlighting their importance in both commercial and everyday applications.

This chart presents the projected growth in applications of water repellent nonwoven materials across various industries by 2025. The data showcases the increasing adoption of these materials in key sectors such as automotive, construction, healthcare, and consumer goods due to their technological advancements in water repellency.

As the demand for sustainable materials grows, the production of water-repellent nonwoven fabrics is increasingly scrutinized for its environmental impact. According to a recent report by the Global Nonwoven Fabrics Market Analysis, the market for nonwoven materials is projected to reach $40 billion by 2026, driven by demands for hygiene products, protective garments, and filtration systems. However, the sustainability of these materials is critical, considering the adverse effects of traditional manufacturing processes that often rely on petrochemical-based inputs.

Sustainability in producing water-repellent nonwovens predominantly hinges on eco-friendly raw materials and energy-efficient processes. Many manufacturers are now turning to bio-based fibers and polymers, such as PLA (polylactic acid) derived from renewable resources, which can significantly reduce the carbon footprint associated with conventional production. A recent life cycle assessment indicated that bio-based nonwovens could cut greenhouse gas emissions by up to 60% compared to traditional polypropylene-based options.

Furthermore, improvements in manufacturing techniques such as needle punching and spunbonding are being optimized to minimize water usage and waste generation. The integration of these sustainable practices not only enhances product appeal but also meets the increasing regulatory pressures for environmentally responsible operations in the textiles industry.