Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

In recent years, the demand for sustainable and versatile materials in the textile industry has surged, with Lamination Nonwoven Fabric emerging as a frontrunner for innovative projects across various sectors. According to a report by Grand View Research, the global nonwoven fabric market is expected to reach USD 63.3 billion by 2025, fueled by a growing emphasis on lightweight, durable, and eco-friendly materials. Lamination Nonwoven Fabric not only meets these criteria but also offers enhanced protection and durability, making it an ideal choice for applications ranging from personal protective equipment to automotive interiors.

The benefits of Lamination Nonwoven Fabric extend beyond mere utility; they also contribute to cost efficiency and environmental sustainability. Advanced lamination processes can significantly improve the fabric's resistance to water, chemicals, and abrasions while reducing the need for additional coatings or treatments. As reported by Research and Markets, innovations in lamination technologies are projected to propel the growth of nonwoven fabrics, which are increasingly favored for their lower environmental impact compared to traditional textile methods.

As we explore the top 10 benefits of Lamination Nonwoven Fabric for your projects, it becomes evident that embracing this material not only aligns with industry trends but also supports sustainable practices in modern fabrication.

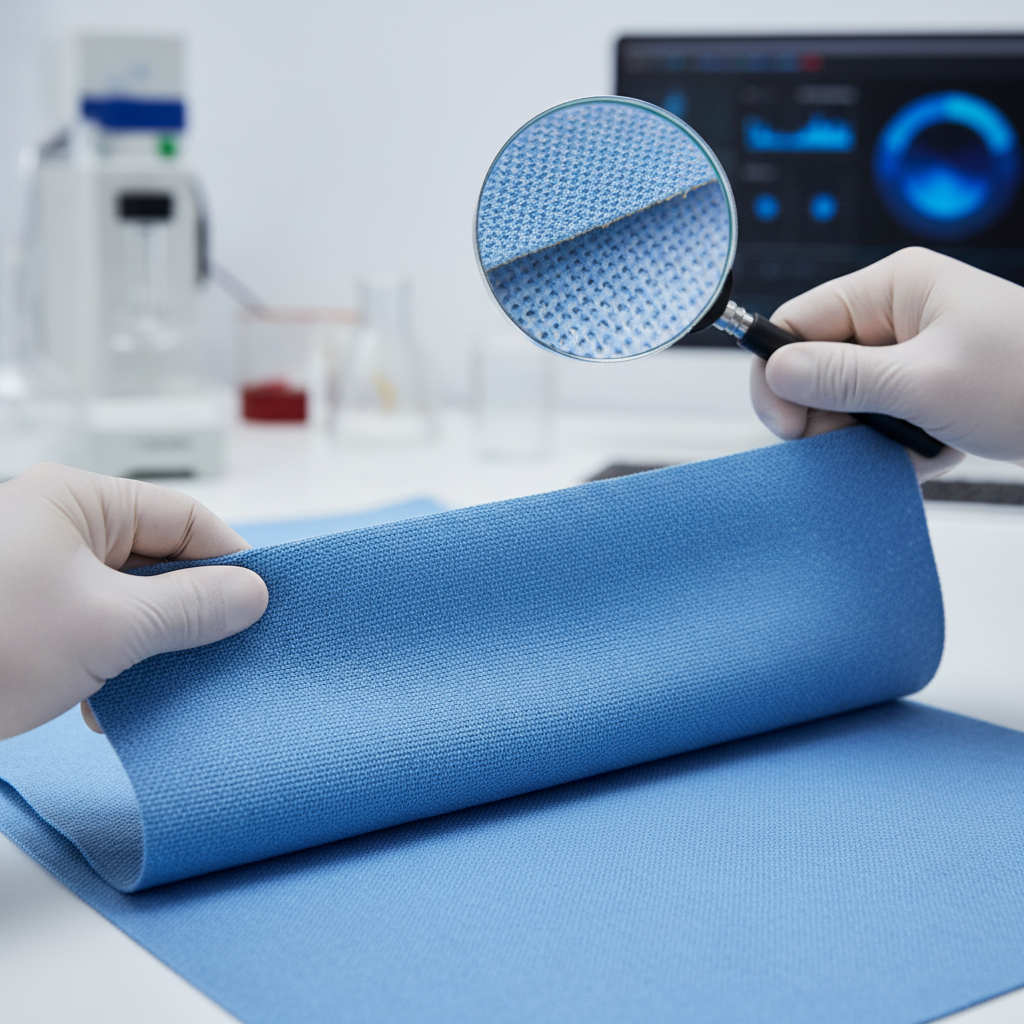

Choosing the right lamination for nonwoven fabrics is crucial, especially in specialized applications like personal protective equipment (PPE) in the healthcare sector. The lamination process enhances the fabric's properties, making it more durable while maintaining comfort. This is particularly important in medical settings where products must provide both barrier protection and the ability to breathe, ensuring comfort for the wearer throughout prolonged use.

Additionally, advancements in fabric coating and laminating technologies have allowed manufacturers to produce nonwoven textiles that meet the high demands of various industries. With globalization enabling a wider range of materials and techniques to enter the market, selecting the appropriate lamination can significantly impact the final product's performance. It is essential for designers and manufacturers to consider these factors to ensure that their projects achieve the desired quality and functionality while adhering to industry standards.

Lamination techniques play a crucial role in enhancing the durability and functionality of nonwoven fabrics across various projects. Among the various types of lamination methods available, each has its unique advantages, allowing for tailored applications depending on specific project requirements. For example, thermal lamination uses heat to bond layers, creating a strong and functional fabric ideal for products that require water resistance and added strength. Another popular technique is adhesive lamination, which applies a bonding substance to attach layers, perfect for achieving flexible yet sturdy materials suited for both industrial and consumer uses.

In recent advancements, the lamination process has expanded to include innovative applications in sectors like renewable energy and electronics. Techniques such as encapsulation in photovoltaic module designs involve using high-performance materials to enhance the efficiency and longevity of solar panels. Similarly, the lamination of high-temperature superconducting tapes showcases how advanced methods can improve electrical performance and material stability, addressing the growing needs of modern technology. Understanding these diverse lamination techniques is essential for professionals seeking to leverage the benefits of nonwoven fabrics in their projects effectively.

Laminated nonwoven fabrics are gaining traction in various industries due to their remarkable properties and versatility. One key advantage of using these materials is their enhanced durability. With air through bonding techniques, which are widely utilized across regions, laminated nonwoven fabrics exhibit improved strength, making them ideal for applications in construction, upholstery, and medical fields. According to recent reports, the demand for durable materials is projected to grow significantly, with the global nonwoven fabric market expanding at a CAGR of around 6% through 2028.

Another significant benefit is the moisture resistance provided by laminated nonwoven fabrics. This property is particularly essential in medical applications where sterility and moisture control are paramount. The fluid dynamics and carding technologies employed in their production facilitate better breathability without compromising on protective qualities. Industries that prioritize hygiene and safety are increasingly adopting these materials, confirming their essential role in product development.

**Tips:** When selecting laminated nonwoven fabrics for your projects, consider their application requirements. Ensure that the fabric's properties—such as weight, strength, and moisture resistance—align with your specific needs. Additionally, evaluate the supply chain and seek manufacturers that have a strong global presence to guarantee consistent product quality.

Lamination nonwoven fabric offers numerous advantages for various projects, especially when focused on enhancing durability and performance. One effective approach to improving these characteristics is to optimize the composite materials used in lamination. Recent studies have demonstrated that by coordinating the strain gradients in the layers of materials such as magnesium and aluminum, enhanced strength and ductility can be achieved. This synergy not only improves performance but also extends the lifespan of products made from these composite materials.

Furthermore, the integration of advanced nanofillers like multi-walled carbon nanotubes (MWCNTs) and silica (SiO2) has proven to significantly enhance the tensile strength of laminated composites. These enhancements are crucial, especially in applications where mechanical resistance is essential. Using methods such as response surface methodology assists in fine-tuning the composition and structure of the laminates, ensuring maximum performance. Additionally, innovative fabrication techniques like creating flame-retardant cellulose nanofiber laminates from environmentally friendly materials demonstrate the potential of combining sustainability with superior physical properties, making lamination nonwoven fabrics a compelling choice for future projects.

This chart illustrates the top 10 benefits of using laminated nonwoven fabric in various projects, highlighting its enhanced durability and performance.

Eco-friendly laminated nonwoven fabrics are gaining traction in various industries, notably in healthcare and personal protective equipment (PPE). These materials are made from renewable sources, reducing reliance on fossil fuels and minimizing environmental impact. They offer excellent barrier properties while remaining lightweight and comfortable, making them ideal for sustainable personal protective clothing, which is crucial for safeguarding healthcare workers against infectious diseases like COVID-19.

The shift toward sustainable options in the nonwoven fabric sector is also beneficial for manufacturing processes. Innovations in production techniques allow for the creation of laminated nonwovens that not only meet high-performance standards but also comply with eco-friendly practices. As consumers and companies increasingly prioritize sustainability, the demand for such materials is projected to grow, shaping the future of technical textiles while addressing environmental concerns effectively.

| Benefit | Description | Eco-Friendly Aspect | Applications |

|---|---|---|---|

| Durability | Increased resistance to wear and tear, extending product life. | Utilizes recycled materials to enhance durability. | Industrial packaging, furniture covers. |

| Water Resistance | Protects products from moisture damage. | Biodegradable laminating films available. | Outdoor applications, protective gear. |

| Lightweight | Easy to handle and durable while maintaining low weight. | Reduced energy consumption in transportation. | Travel bags, disposable products. |

| Versatility | Adaptable to various applications and industries. | Options for compostable materials. | Medical, automotive, home textiles. |

| Cost-Effectiveness | Reduces overall project costs by minimizing waste. | Recyclable options help lower costs long-term. | Manufacturing, packaging. |

| Aesthetics | Improves the visual appeal of products. | Natural look and feel with eco-friendly finishes. | Fashion, promotional materials. |

| Ease of Cleaning | Surface is easy to wipe and maintain. | Cleanable with biodegradable products. | Home textiles, medical applications. |

| Thermal Insulation | Helps in maintaining temperature for sensitive products. | Insulating materials can be made with sustainable sources. | Food packaging, thermal apparel. |

| Hygiene | Maintains cleanliness, suitable for sanitary products. | Usage of non-toxic, eco-friendly materials. | Medical, personal care products. |

| Customizability | Available in various colors, textures, and sizes. | Custom options with sustainable practices. | Promotional products, branding materials. |