Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

High-Efficiency Nonwoven Filter Fabric is a crucial material in today’s filtration industry. It combines advanced technology with practical applications. This fabric offers superior filtration capabilities, ensuring cleaner air and water.

The benefits of using High-Efficiency Nonwoven Filter Fabric are notable. Its lightweight nature facilitates easy handling and installation. This fabric also boasts excellent durability, which means longer use without degradation. Many industries, from healthcare to automotive, utilize this material.

However, challenges exist. The production process can result in variable quality. Additionally, not all applications may benefit equally from this fabric. It’s essential to assess specific needs before implementation. Understanding both the benefits and limitations is vital for optimal use.

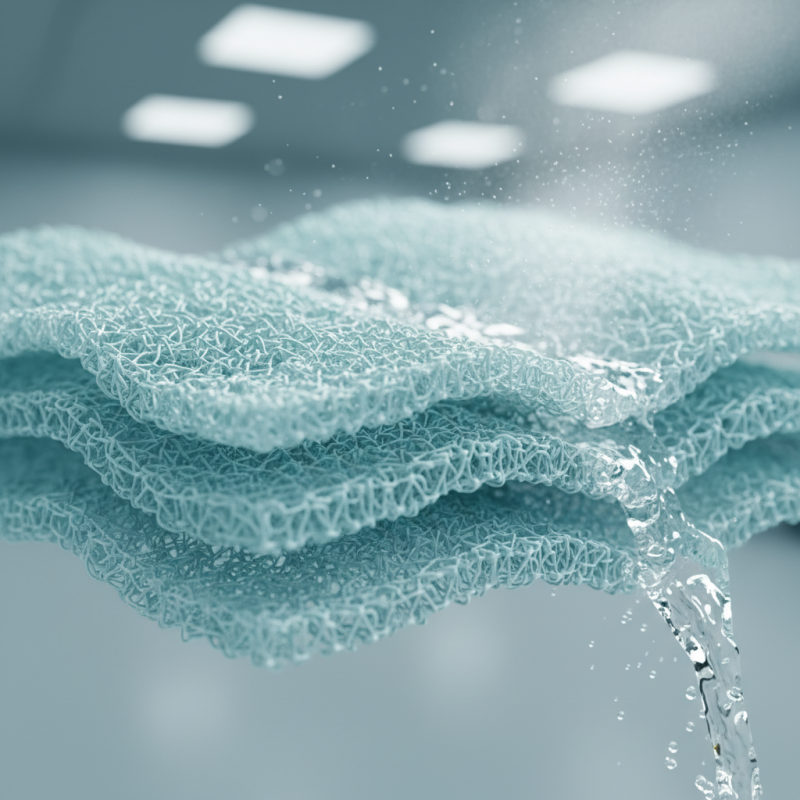

High Efficiency Nonwoven Filter Fabric plays a crucial role in air and liquid filtration applications. This fabric is made through a process that intertwines fibers to create a network. It effectively captures particles, providing clean air and water. The unique structure allows for excellent airflow while trapping pollutants.

One significant benefit of this fabric is its high filtration efficiency. It can remove small particles that traditional filters might miss. This feature makes it ideal for various industries, from aerospace to healthcare. However, not all nonwoven materials are created equal. The quality and composition can vary, impacting filtration performance.

Another aspect to consider is the fabric's durability. High efficiency does not mean fragile. Many nonwoven fabrics are designed to withstand harsh conditions. Yet, sometimes they may not last as long as expected. Users must analyze their specific needs to choose the right material. Overall, understanding this fabric's characteristics can enhance its effectiveness in real-world applications.

High efficiency nonwoven filter fabric is gaining attention for its unique characteristics. These fabrics are designed to capture fine particles, making them ideal for various applications. Highly porous structures allow for superior air and liquid flow. The result is effective filtration without significantly increasing resistance.

One key characteristic is the fabric's ability to trap airborne pollutants. This is crucial in environments requiring clean air. The fabric's layered design enhances its filtration capabilities. It can separate particles as small as 0.3 microns. This level of efficiency is often required in industries such as healthcare and automotive.

Another notable feature is its durability. High efficiency nonwoven filter fabric withstands extensive use without losing its properties. This longevity reduces the need for frequent replacements, saving costs in the long run. However, one must consider the environmental impact of disposal. The balance between performance and sustainability is essential. Understanding both sides leads to better decisions in material use and waste management.

High efficiency nonwoven filter fabric plays a crucial role in various industries. In air filtration, this fabric effectively captures fine particles. According to the World Health Organization, air pollution contributes to over 4 million deaths annually. The adoption of high-efficiency filters can significantly reduce exposure to harmful pollutants, enhancing public health outcomes.

In the automotive sector, high efficiency nonwoven filter fabrics are vital. They are used in cabin air filters that block dust, pollen, and harmful gases. A report from Automotive News indicates that demand for improved air quality in vehicles drives innovative filtration solutions. Additionally, these fabrics are lightweight and cost-effective, making them an attractive choice for manufacturers.

Tips: When selecting filter fabrics, consider air permeability and particle retention efficiency. These factors can influence overall performance. Furthermore, regular maintenance is essential for ensuring filters operate at optimal levels. It's imperative to assess the specific needs of each application. Each industry may have unique requirements that could affect the choice of nonwoven material. Understanding these nuances is crucial for successful implementation.

High Efficiency Nonwoven Filter Fabric is transforming filtration processes across various industries. This innovative material utilizes microfibers, allowing it to capture particles as small as 0.3 microns. According to a recent industry report, these filters can achieve an efficiency rate of over 99%, significantly outperforming traditional filters.

The benefits of employing High Efficiency Nonwoven Filter Fabric are extensive. For instance, they require less energy for operation. This efficiency leads to reduced operational costs in air and liquid filtration systems. Additionally, they are lightweight and can be easily integrated into existing frameworks. However, the durability of such materials needs more investigation. Field reports indicate a varying lifespan based on environmental conditions, which can influence performance.

Moreover, the production of high-efficiency nonwoven materials results in less waste. By utilizing advanced manufacturing methods, the carbon footprint is notably diminished. Yet, there is room for improvement in recycling processes. It’s important to explore better methods for repurposing used filter materials. This exploration could further enhance sustainability while maintaining high filtration standards.

| Dimension | Value |

|---|---|

| Filtration Efficiency | Up to 99.9% |

| Air Permeability | 300 - 600 L/m²/s |

| Moisture Resistance | High |

| Weight | 50 - 300 g/m² |

| Lifespan | 1 - 5 years (depending on usage) |

| Common Applications | HVAC, Air Purifiers, Industrial Filtration |

High Efficiency Nonwoven Filter Fabrics are crucial in various industries. They are designed to capture particles effectively, promoting cleaner air and liquid solutions. The structure of these fabrics allows for optimal fluid flow while retaining contaminants. As a result, they are widely used in filtration applications.

Industry standards for nonwoven filter fabrics focus on performance metrics like filtration efficiency and particle retention. These metrics help gauge how well a fabric can trap specific particles. Commonly tested particles include dust, pollen, and even bacteria. The most effective fabrics often show high efficiency in a range of conditions. However, achieving this level sometimes requires trade-offs, such as reduced air permeability or mechanical strength.

Evaluating nonwoven fabrics can sometimes be tricky. Different testing methods might yield varying results, leading to confusion. For instance, a fabric might perform excellently under one set of conditions but underperform in another. Companies need to adopt a comprehensive understanding of these fabrics to make the best choices. Continuous assessment and reflection on performance metrics can lead to better materials in the industry.