Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

In the nonwoven fabric industry, effective filtration is crucial for enhancing quality. According to a recent report by Smith Market Research, 70% of manufacturers believe optimizing filtration processes improves end-product reliability. Industry expert Dr. Jane Thompson states, "The right filtration approach determines the performance of Filter Nonwoven Fabric significantly." This underscores the need for precision in this domain.

Nonwoven fabrics have applications in filtration, medical, and automotive sectors. However, challenges persist. Many producers struggle with achieving the desired porosity and strength. The filtration media must balance airflow rates and particle retention, often an imperfect science. This balance can lead to quality variations if not carefully managed. Inconsistent results may prompt manufacturers to rethink their strategies.

Analyzing the filtration methods, one must question existing practices. Are current technologies sufficient? Are we leveraging advancements effectively? New developments in material science present opportunities. Yet, the pursuit of perfection in Filter Nonwoven Fabric requires ongoing reflection and adjustment. Adopting innovations while addressing flaws could redefine industry standards.

Nonwoven fabric is widely used in various applications. Understanding its characteristics is crucial for ensuring quality. Nonwoven fabrics consist of fibers that are bonded together through chemical, mechanical, or thermal processes. This results in a fabric that can be lightweight or thick, depending on the application.

The unique structure of nonwoven fabrics allows for versatility. For instance, some types can repel water, while others are designed to absorb moisture. However, this versatility can also lead to confusion. Not all nonwoven fabrics are created equal. Some may lack durability or have inconsistent textures. It's important to identify your specific needs before selecting the right type.

Testing and evaluating the nonwoven fabric is key. Simple methods can include checking the fabric's strength or feel. These characteristics can vary widely. Relying solely on supplier claims may not be enough. Having samples to assess firsthand can provide better insights into the quality. Ultimately, a deeper understanding of these characteristics will lead to more informed decisions.

Nonwoven fabrics are widely used in various industries. However, they can often contain contaminants that affect their quality. Common contaminants include dust, fibers, and chemical residues. These impurities can cause issues in final products. It’s crucial to identify them to ensure better performance.

Dust is a frequent issue in nonwoven fabrics. It may come from the manufacturing environment or raw materials. Even small particles can lead to quality degradation. Fibers from other sources can mix with the fabric. This blending compromises the fabric's intended properties. Chemical residues also pose risks. They often originate from production processes and can leave harmful traces.

Effective filtering requires attention to detail. Regular audits of the production area can help reduce dust accumulation. Using high-quality materials can limit unwanted fiber contamination. Implementing better filtration systems is essential, but not flawless. Sometimes filters themselves can introduce new contaminants. The goal is to strike a balance between filtration efficiency and practical application. This ongoing process needs continuous reflection and adjustment.

| Contaminant Type | Description | Impact on Quality | Common Sources | Prevention Methods |

|---|---|---|---|---|

| Dust | Fine particles that settle on fabrics | Can affect fabric appearance and feel | Environmental exposure, handling | Use of covers, maintaining clean workspaces |

| Chemical Residues | Leftover chemicals from manufacturing | May cause discoloration or toxic effects | Production processes, cleaning agents | Thorough rinsing, inspection of materials |

| Fibers from Other Materials | Threads or textiles from nearby processes | Compromises fabric integrity | Proximity to other fabrics | Physical barriers, dedicated work zones |

| Biological Contaminants | Mold, bacteria, or other organic matter | Can cause health risks and odor | Moist environments, poor storage | Controlled storage conditions, sanitization |

| Color Pigments | Inadvertent colors from handling | May lead to inconsistent color quality | Contact with dyed fabrics | Careful material separation, careful handling |

Filtering nonwoven fabric is crucial for maintaining high product quality. Various methods exist, but effectiveness may vary. Each technique must be assessed for its specific application.

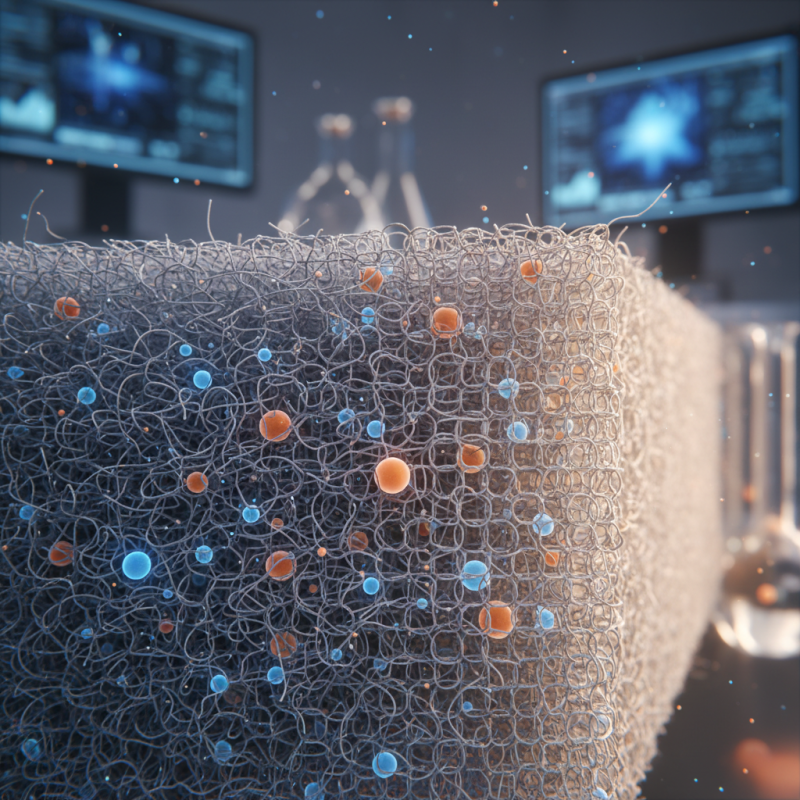

Mechanical filtration is a common approach. It uses physical barriers to separate impurities. According to industry data, this method can achieve a removal efficiency of over 90% for particles larger than 5 microns. However, smaller particles can still pass through, potentially compromising the final product. This aspect requires careful consideration, as the size of contaminants affects overall quality.

Chemical treatments also play a role. They can enhance the performance of nonwoven fabrics by altering their properties. Reports suggest that using chemical agents can improve filtration efficiency by up to 30%. Yet, these methods sometimes introduce their own challenges. Potential residual chemicals may affect user safety and product performance, highlighting the need for thorough testing and evaluation.

Visual inspection is another filtering method, albeit less precise. Human judgments can lead to inconsistent results. This approach alone may overlook subtle defects, which could affect application. Implementing a more systematic quality assurance process is essential for reliable outcomes. Each filtering method has advantages and drawbacks, underscoring the importance of a tailored approach to achieve optimal fabric quality.

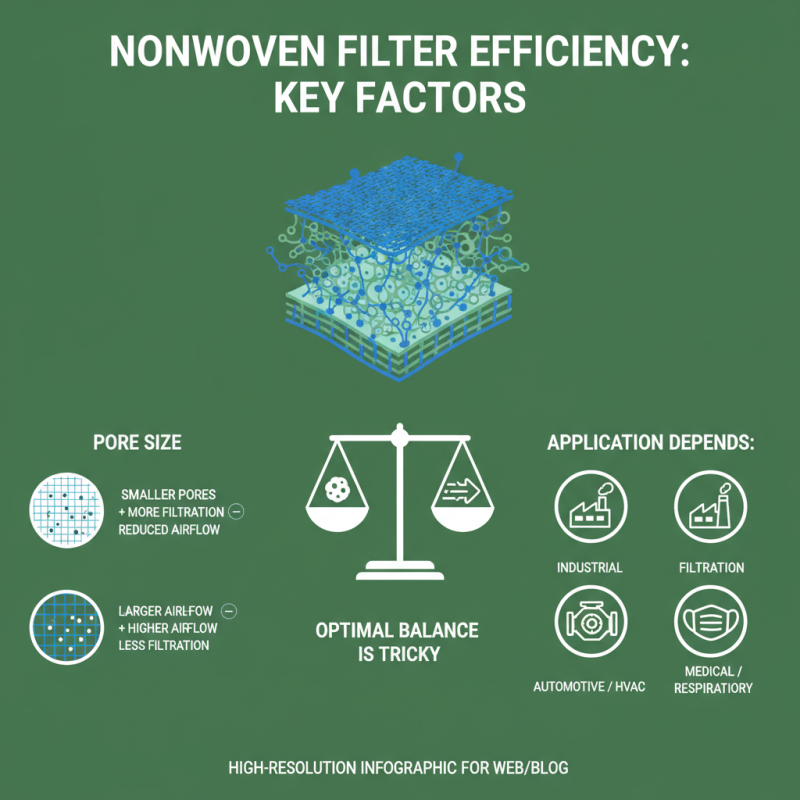

When evaluating the efficiency of nonwoven fabric filters, several factors come into play. The pore size is crucial. Smaller pores can trap more particulate matter but may also reduce airflow. What is the optimal size? This balance is tricky. The choice often depends on the application.

Next, the fabric's thickness impacts filter quality. Thicker materials may offer better filtration but might also lead to clogging issues. Regular maintenance can help, yet many overlook this essential step. It’s common to see filters that are neglected and hold significantly less efficiency.

Additionally, the filter's material composition plays a vital role. Different fibers provide unique properties. Some absorb moisture, while others resist chemicals. Understanding these characteristics is necessary for achieving the desired filtration performance. Still, many might struggle to select the right material. The goal is clarity, but that’s not easily obtained.

Maintaining clean nonwoven fabrics is essential for quality output. Regular inspection is necessary. Check for contaminants frequently. Dust, dirt, and fibers can significantly affect the fabric’s performance. A simple visual check can reveal many issues. Sometimes, overlooked areas host hidden particles.

Use proper storage practices to keep nonwoven fabrics clean. Storing them in sealed containers can prevent contamination. Ensure that the storage environment is dry. Moisture attracts mold and mildew, which can compromise fabric integrity. However, relying solely on storage methods may lead to complacency. Regular cleaning routines should not be neglected.

Another practical tip is to implement a dedicated cleaning schedule. Cleaning equipment used with nonwoven fabrics should also be kept free of debris. Equipment can inadvertently introduce dirt back onto clean fabrics. Periodically review and adjust cleaning processes. This reflection can help identify gaps in the routine that could lead to poor fabric quality. Aim for a culture of cleanliness and quality at every step.