Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

When considering materials for your projects, "Nonwoven Fabric Needle Punched" stands out as a versatile option. According to a report by Market Research Future, the nonwoven fabric market is projected to reach 53 billion USD by 2025. This growth highlights the increasing application of nonwoven fabrics across various industries.

Choosing the right needle punched fabric can be challenging. Factors such as durability, weight, and texture come into play. For example, the agricultural sector uses needle punched fabrics for erosion control and ground cover. Surprisingly, some users overlook the specific needs of their projects when selecting materials. This can lead to performance issues.

Understanding the properties of Nonwoven Fabric Needle Punched is crucial. These fabrics exhibit strength and are lightweight. However, achieving the right balance can be tricky. Not every needle punched fabric is suitable for all applications. It's important to evaluate your project requirements. Make sure to ask questions and seek advice from industry experts.

When choosing nonwoven fabric, understanding its types and properties is crucial. Nonwoven fabrics are categorized into different types such as spunbond, meltblown, and needle punched. Each offers unique characteristics. For instance, needle-punched nonwoven fabric is known for its strength and durability. According to industry data, the global nonwoven fabric market is projected to reach $50 billion by 2025, illustrating the growing demand for such materials.

The properties of the fabric can vary significantly. Needle-punched fabrics generally exhibit excellent filtration, insulation, and absorbency. These characteristics make them suitable for various applications, including automotive, medical, and geotextiles. However, one must be cautious. Not all needle-punched fabrics are created equal. Variations in density and thickness can impact performance.

It's also vital to consider environmental factors. While many nonwoven fabrics are recyclable, the processes vary. Some can be recycled multiple times, while others cannot. Data shows that only about 20% of nonwoven materials are currently being recycled. This highlights a need for greater focus on sustainability in the industry. The choice of nonwoven fabric requires careful reflection on these crucial aspects.

When selecting needle punched nonwoven fabrics, several key factors influence your decision. One important aspect is the fabric's density. Thicker fabrics generally provide better durability and strength. According to industry data, a density of 120-180 g/m² is ideal for most applications. However, thicker materials may be less flexible. Consider the trade-off between flexibility and durability.

Another critical factor is the fiber composition. Synthetic fibers, such as polyester or polypropylene, offer excellent moisture resistance. Natural fibers can provide breathability but may not withstand harsh conditions. Each option has its pros and cons. Analyze your project's requirements carefully before making a choice.

Tips: Always request samples to test in your projects. This helps you evaluate their performance under real conditions. Don’t forget to consider the manufacturing process. Needle punching can affect the fabric's texture and appearance. Ensure it aligns with your project’s aesthetic needs. A mismatch could lead to wasted resources and disappointment. Always review your options with an open mind. Embrace the nuances of each choice, as they can lead to unexpected insights.

When choosing needle-punched nonwoven fabric for your projects, fabric weight and thickness are crucial factors. A lightweight fabric, usually weighing under 100 grams per square meter, is perfect for crafts like facial masks or light insulation. Heavier fabrics, on the other hand, can provide more durability and support. Think about the purpose of your project carefully. You might want something thick for structural integrity, or perhaps something thin for flexibility.

Consider how the fabric will be used. If it's for outdoor use, a thicker fabric can resist wear and tear better. But too much weight can make your project cumbersome. Lightweight choices are easier to manipulate, but they may lack the strength needed for demanding applications. Testing samples can be helpful. You might find that a fabric looks perfect online, but in reality, it could feel different.

Don’t overlook the importance of thickness. A thicker fabric can offer better thermal insulation, while thinner varieties may be easier to sew and layer. Understanding your specific project needs is essential. Engage in some trial and error—what works for others might not work for you. Reflect on your choices and be open to adjustments.

| Project Type | Recommended Fabric Weight (g/m²) | Thickness (mm) | Common Applications |

|---|---|---|---|

| Craft Projects | 60-80 | 0.3-0.5 | Bags, Decorations |

| Medical Applications | 80-120 | 0.5-1.0 | Surgical Drapes, Masks |

| Agricultural Use | 100-150 | 0.6-1.2 | Crop Covers, Plant Protection |

| Industrial Applications | 120-200 | 0.8-1.5 | Industrial Fabrics, Insulation |

When selecting nonwoven fabric for projects, it’s essential to consider its durability and performance. Durability ensures that the fabric withstands wear and tear. For example, needle-punched nonwoven fabrics are made by mechanically entangling fibers together. This method enhances strength. However, some fabrics might not offer the same resilience. Testing different samples can help you find the right one.

Performance features are equally important. Look for fabrics that can resist moisture, mold, and other environmental factors. Some nonwoven fabrics are breathable, making them suitable for various applications. It’s vital to evaluate how the fabric behaves under stress or strain. A fabric might look perfect but could fail under pressure.

Remember to pay attention to how well it holds up when exposed to different conditions. This reflection can save time and resources in the long run. It's a balance between functionality and sustainability.

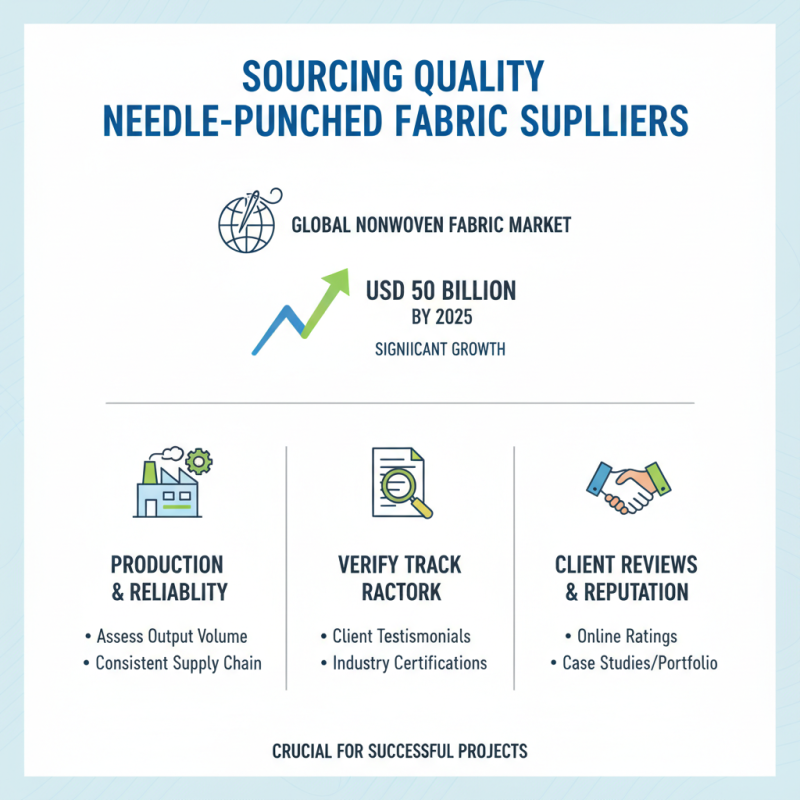

Sourcing quality suppliers for needle punched fabrics is crucial for successful projects. The global nonwoven fabric market is projected to reach USD 50 billion by 2025, showing significant growth. This indicates an increasing demand for materials across various industries. When selecting suppliers, consider their production capacity and reliability. Verify their track record and client reviews.

Many suppliers may claim quality, but not all match the same standards. It's essential to request samples before committing. A report by Smithers Pira highlights that 25% of customers faced issues with fabric consistency. This underscores the importance of testing. Understanding the supplier's manufacturing processes can help assess their capabilities. Moreover, geographical proximity can affect shipping costs and delivery times.

Transparency is key in establishing trust. Some suppliers might not disclose their sourcing methods. This raises concerns about sustainability and ethical practices. In an industry that is becoming more eco-conscious, ensuring your suppliers align with these values is vital. Identifying a reliable supplier can be challenging, but careful research prevents future setbacks.