Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

Lamination Nonwoven Fabric has become an essential component in various industries, from healthcare to automotive and beyond. As reported by the Nonwovens Industry Association, the global market for nonwoven fabrics is expected to reach $50 billion by 2026, driven largely by the increasing demand for high-performance materials. With an array of options available, selecting the best Lamination Nonwoven Fabric for your projects can significantly impact quality and cost-effectiveness.

According to Dr. Helen Zhang, a leading expert in the nonwoven fabric sector, "The right choice of Lamination Nonwoven Fabric can enhance product durability and functionality while reducing overall weight." This underscores the importance of understanding the specific requirements of your application when choosing the material. Factors such as thickness, adhesion properties, and environmental resistance should all be considered to ensure optimal performance. By evaluating these criteria, manufacturers and engineers can maximize the benefits of Lamination Nonwoven Fabric in their projects, leading to innovative solutions across various fields.

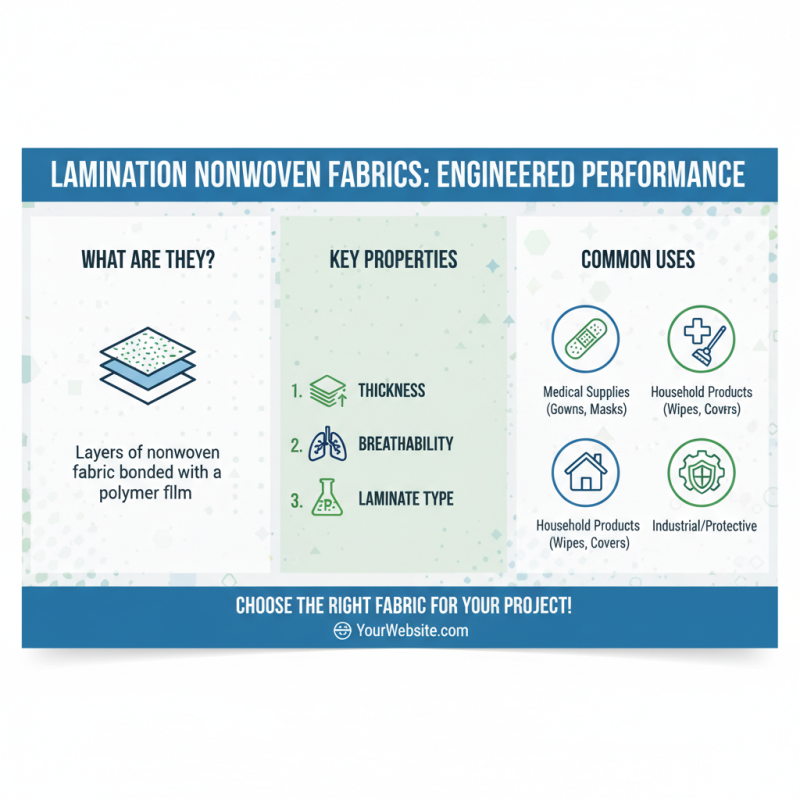

Lamination nonwoven fabrics are engineered materials that are created by bonding layers of nonwoven fabric with a polymer film. This process enhances the structural integrity and durability of the fabric, making it suitable for a variety of applications ranging from medical supplies to household products. Understanding the basic properties of lamination nonwoven fabrics is crucial when selecting the right type for your project. Key attributes to consider include thickness, breathability, and the type of laminate used, as these factors can significantly affect the performance and suitability of the fabric for specific tasks.

When embarking on a project that requires lamination nonwoven fabrics, it's essential to understand how these materials interact with various environmental factors. For instance, some laminates can provide water resistance, while others may offer breathability. Evaluating the intended use of the fabric will guide you in choosing the most appropriate type. Additionally, take into account the fabric's weight and texture, as these can influence handling and sewing capabilities, particularly for projects that involve intricate designs or demanding applications. Understanding these fundamentals will empower you to select the best lamination nonwoven fabric that meets your project's needs efficiently.

When choosing the best lamination nonwoven fabric for your projects, several key factors should be considered. Firstly, the fabric's weight and thickness play crucial roles in determining its durability and suitability for specific applications. According to industry reports, nonwoven fabrics typically range from 30 to 250 grams per square meter (gsm), and selecting the right weight can significantly affect the performance of the final product. For instance, lighter fabrics may be ideal for disposable applications, while heavier options offer more robust solutions for reusable products.

Another critical aspect is the type of polymer used in the nonwoven fabric. Different polymers provide unique properties such as water resistance, UV protection, and breathability. A report by the Nonwoven Technical Association highlights that polypropylene-based nonwovens account for over 40% of the global market, primarily due to their versatility and excellent mechanical properties. Understanding the specific requirements of your project can help you select the most appropriate polymer type.

Tips: When evaluating nonwoven fabrics, always request samples to assess texture, flexibility, and overall performance. Additionally, check for certifications regarding environmental impact, as many manufacturers now offer eco-friendly options that align with sustainability goals. Lastly, consider the intended end-use of the product, as this will guide your choices in both material and construction techniques.

When choosing lamination techniques for nonwoven fabrics, it is crucial to understand the various methods available, each with its distinct advantages and applications. Common lamination techniques include adhesive lamination, thermal lamination, and extrusion lamination. According to industry reports, the global nonwoven fabric market was valued at approximately USD 45 billion in 2022 and is projected to grow at a CAGR of 5% from 2023 to 2030, indicating a strong demand for high-quality laminated nonwoven products.

Adhesive lamination is popular for producing durable, flexible materials and is often used in personal protective equipment and upholstery. In contrast, thermal lamination utilizes heat and pressure to bond layers of fabric seamlessly, making it ideal for applications requiring high levels of waterproofing and strength. Extrusion lamination, whereby molten resin is used to bond materials together, is especially beneficial for creating multilayered fabrics designed for agricultural and industrial use.

Tips: When selecting a lamination technique, consider the end-use of the nonwoven fabric. Understand the mechanical and chemical resistance required for your project, as well as any environmental conditions the fabric will face. Additionally, evaluate the cost-effectiveness of each method to ensure that it aligns with your budget constraints while meeting quality standards. By taking these factors into account, you can make an informed decision that will enhance the longevity and performance of your final product.

Lamination nonwoven fabrics have gained significant traction across various industries due to their unique properties and versatile applications. The global nonwoven fabric market size is projected to reach $50.5 billion by 2028, showcasing a compound annual growth rate (CAGR) of 5.5% from 2021 to 2028. This growth is largely driven by the increasing demand for durable and lightweight materials in medical, hygiene, automotive, and construction sectors.

In the medical industry, lamination nonwoven fabrics are widely utilized for disposable gowns, masks, and drapes due to their excellent barrier properties and comfort. The healthcare segment alone accounted for approximately 30% of the global nonwoven market in 2020, reflecting a surge in demand for protective equipment, particularly during health crises. Additionally, in the hygiene industry, these fabrics are essential in the production of products like feminine hygiene items and adult incontinence pads, where absorbency and skin-friendliness are crucial.

Furthermore, the automotive sector has started to embrace lamination nonwoven fabrics for interior applications, providing sound insulation and enhancing aesthetics while reducing vehicle weight. Reports indicate that the automotive segment is expected to witness a substantial increase in market share, driven by a focus on sustainability and the use of lightweight materials, which can help improve fuel efficiency. As industries continue to explore innovative solutions, the potential applications of lamination nonwoven fabrics are set to expand, highlighting their importance in modern manufacturing processes.

When working on projects involving lamination nonwoven fabric, proper maintenance and care are essential to ensure longevity and performance. Regular cleaning is a key component; it is advisable to use a damp cloth or sponge with mild soap to wipe off dirt and stains. Avoid harsh chemicals or abrasive materials that can degrade the fabric's surface. For machine-washable varieties, a gentle cycle with cold water is often suitable. Always check the manufacturer's guidelines, if available, for specific instructions on cleaning procedures.

Storage is another critical factor in maintaining the quality of lamination nonwoven fabric. It should be kept in a cool, dry place, away from direct sunlight to prevent fading and deterioration. When storing, roll the fabric rather than folding it to avoid creases that may be hard to remove later. If the projects require prolonged exposure to moisture or varying temperatures, consider protective coverings to shield the fabric from environmental factors. With consistent care, lamination nonwoven fabric can retain its functional and aesthetic qualities for many projects to come.

| Fabric Type | Weight (gsm) | Durability | Water Resistance | Maintenance Required |

|---|---|---|---|---|

| Polypropylene | 80 | High | Yes | Low |

| Polyester | 120 | Medium | Moderate | Medium |

| Cotton Blend | 150 | Medium | No | High |

| Spunbond | 90 | Very High | Yes | Low |

| SMS (Spunbond-Meltblown-Spunbond) | 60 | High | Yes | Very Low |