Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

In today's rapidly evolving industrial landscape, the demand for safety and performance in materials has never been more critical. One such material that has gained significant attention is Flame Retardant Nonwoven. These specialized nonwoven fabrics are designed to resist ignition and slow down the spread of flames, making them essential components in various applications, including automotive, construction, and protective clothing. As safety regulations tighten and consumer expectations rise, understanding how to choose the best Flame Retardant Nonwoven for specific needs becomes imperative.

Selecting the right Flame Retardant Nonwoven involves evaluating several key factors, including the inherent fire-resistant properties, the intended application, and compliance with relevant safety standards. Additionally, considerations such as durability, comfort, and environmental impact play a crucial role in the decision-making process. As we delve deeper into the intricate world of flame-retardant materials, this guide aims to provide valuable insights and criteria that will aid manufacturers and end-users in making informed choices that not only enhance safety but also elevate performance across diverse applications.

Flame retardant nonwovens are engineered materials designed to resist ignition and slow the spread of fire. They are commonly utilized in applications where safety is paramount, such as in transportation, construction, and protective clothing. Understanding the properties and benefits of these materials is crucial when selecting the right type for specific needs. Flame retardant nonwovens can be produced from a variety of fibers, including polyester, polypropylene, and natural fibers, each offering different levels of fire resistance and durability. The choice of fiber, treatment process, and fabric weight can significantly influence the performance of the nonwoven in high-temperature environments.

When assessing flame retardant nonwovens, it is essential to consider the specific fire safety standards applicable to your industry. These standards outline the requirements for flame resistance, including the time it takes for a material to ignite, the rate of flame spread, and smoke emissions. Additionally, the application environment plays a vital role; for instance, nonwovens used in industrial settings may need to withstand harsher conditions compared to those intended for home furnishings. By thoroughly understanding both the material properties and the relevant safety regulations, users can make informed decisions and ensure the highest level of protection in their applications.

This bar chart illustrates the ignition resistance time of various flame retardant nonwoven materials. When selecting the right material, consider the time it takes for ignition, as this can significantly impact safety in applications where fire resistance is critical.

When selecting the best flame retardant nonwoven fabric for your specific needs, it is crucial to evaluate several key properties that influence safety and performance. One of the primary factors to consider is the fabric's ignition resistance. This property indicates how well the material can withstand exposure to flames and reduce the likelihood of combustion. Look for nonwovens that pass international standards for flame resistance, ensuring they provide adequate protection in various applications.

Another important property to examine is thermal stability. Fabrics with high thermal stability can retain their structural integrity when exposed to elevated temperatures, minimizing the risk of melting or degradation. This quality is vital in environments where heat exposure is a concern, such as in industrial settings or during transportation. Additionally, assess the fabric's smoke generation and toxicity characteristics, as materials that produce less smoke and fewer harmful gases during combustion are desirable for safety reasons. By focusing on these key properties, you can better match a flame retardant nonwoven to your specific requirements, ensuring both safety and performance in your applications.

When selecting the best flame retardant nonwoven materials for your applications, understanding fire safety standards is essential. Nonwoven fabrics used in various sectors such as automotive, construction, and healthcare must adhere to specific fire safety protocols to minimize risks. According to a report from the National Fire Protection Association (NFPA), fire-related incidents in residential and commercial buildings account for approximately 50,000 reported fires annually in the United States, emphasizing the critical need for reliable flame-retardant materials.

Familiarize yourself with standards such as ASTM E84, which measures the surface burning characteristics of building materials, including nonwovens. Materials that pass this test achieve a lower flame spread index, indicating better fire resistance. Additionally, the European Union’s EN 13501-1 classification system provides a comprehensive framework for evaluating flame retardancy in textiles, clarifying which nonwoven options meet required safety levels.

Tips: When evaluating nonwoven materials, always request the test results and certifications from suppliers to ensure compliance with existing fire safety standards. Additionally, consider the specific environment where these materials will be used, as conditions such as exposure to heat and smoke levels can drastically impact performance. Always prioritize products that are tested for end-use applications to ascertain their effectiveness in real-world scenarios.

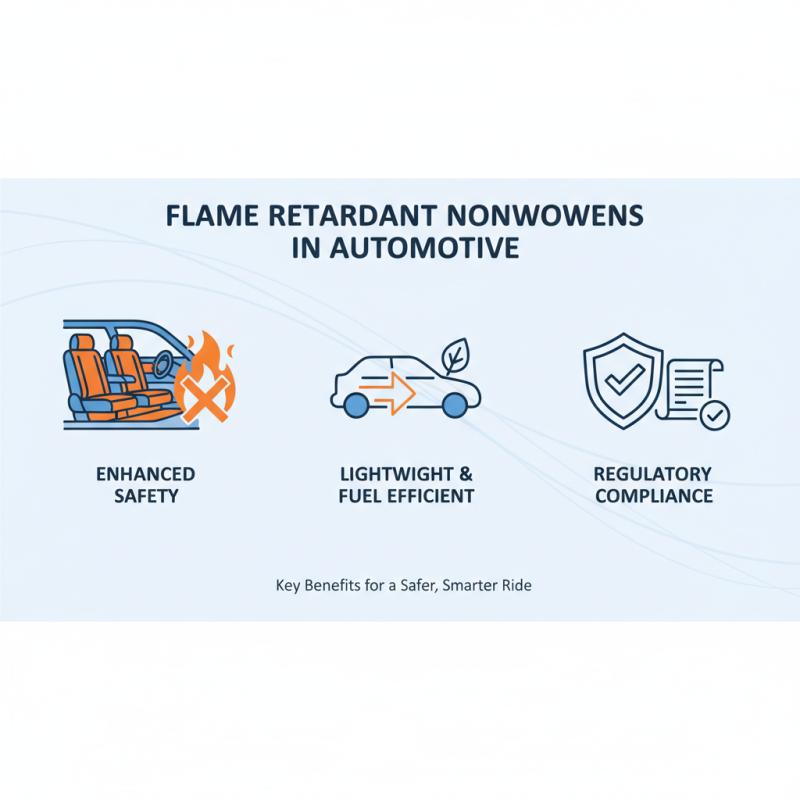

Flame retardant nonwovens play a crucial role in various industries due to their ability to resist ignition and slow down the spread of fire. In the automotive sector, these materials are essential for enhancing passenger safety. They are commonly used in vehicle interiors, such as upholstery and insulation, where they help to minimize fire hazards and comply with safety regulations. Additionally, the lightweight nature of nonwovens contributes to fuel efficiency, making them an attractive option for manufacturers looking to reduce overall vehicle weight.

In the construction industry, flame retardant nonwovens are employed in insulation materials, roofing membranes, and fireproof barriers. These products provide essential protection against the spread of flames, helping to safeguard buildings and ensure compliance with fire safety codes. Their versatility allows them to be integrated into various building designs, contributing to overall fire resistance while maintaining aesthetic and functional qualities. Furthermore, their applications in the protective clothing sector, especially for firefighters and industrial workers, highlight their importance in providing safety against heat and flame hazards.

When selecting flame retardant nonwoven fabrics, it is essential to understand the various types of flame retardants available and their respective properties. Common flame retardants include halogenated compounds, phosphorus-based agents, and inorganic materials. Halogenated flame retardants are known for their effectiveness but can raise environmental concerns. Phosphorus-based flame retardants provide a balance between safety and performance, often enhancing the material's resistance to ignition. Inorganic options, such as ammonium polyphosphate, are increasingly popular due to their non-toxic nature and sustainability.

Tips: When evaluating flame retardant nonwoven fabrics, consider the specific application and required performance standards. For instance, materials used in automotive or construction applications may demand higher flame resistance and durability than those used in everyday consumer products. Always check if the flame retardant meets your region's regulatory requirements, as this can significantly influence your choice.

Another crucial aspect is the processing conditions of the nonwoven fabrics during manufacturing. Some flame retardants may affect the fabric's texture, strength, or overall appearance. It is advisable to request samples for thorough testing in your intended application. Ensure that the selected flame retardant nonwoven fabric not only meets safety standards but also aligns with the aesthetic and functional qualities desired for your project.

| Flame Retardant Type | Application | Performance Rating | Toxicity Level | Cost (per kg) |

|---|---|---|---|---|

| Brominated Compounds | Textiles for aviation | High | Moderate | $10 |

| Phosphate Esters | Furniture coverings | Medium | Low | $8 |

| Mineral-based Flame Retardants | Industrial applications | Very High | Non-toxic | $12 |

| Melamine-based Flame Retardants | Building materials | High | Moderate | $9 |

| Non-halogenated Flame Retardants | Consumer textiles | Medium | Low | $11 |