Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

In today's industrial landscape, the choice of materials impacts efficiency and sustainability. Durable Nonwoven Filter Fabric has emerged as a preferred solution in various applications. According to a report by the Technical Nonwovens Association, the demand for nonwoven filter materials is projected to grow by 5% annually. This trend underscores the need for reliable, high-performance fabrics.

Experts in the field, like Dr. Sarah Thompson, stress the importance of quality. She mentions, "Choosing robust nonwoven materials is essential for effective filtration and longevity." Durable Nonwoven Filter Fabric offers significant advantages, including excellent filtration efficiency and mechanical strength. These features make it suitable for both industrial and environmental projects.

However, there are challenges in the selection process. Not all nonwoven materials meet the stringent requirements for specific applications. It's crucial to evaluate the performance characteristics carefully. A poor choice can lead to inefficiencies and increased costs. Ultimately, opting for the right Durable Nonwoven Filter Fabric can greatly enhance project outcomes and sustainability.

Nonwoven filter fabric provides an innovative solution for various filtration needs. But what exactly is nonwoven filter fabric? It is a type of fabric created from synthetic or natural fibers. These fibers are bonded together through various processes, like heat or chemical treatments. This unique production method results in a lightweight yet durable material. It does not rely on weaving or knitting, which often makes it more versatile.

The structure of nonwoven fabric allows for excellent filtration efficiency. It can trap particles of different sizes without losing flexibility. This adaptability is crucial in projects where space is limited. For example, it finds use in water treatment and air filtration systems. However, not all nonwoven materials are created equal. Some may degrade under harsh conditions, affecting their performance. Users must consider the environment where the fabric will be applied. Testing and research become vital to ensure the right type is chosen for specific needs.

When selecting nonwoven filter fabric, it's essential to weigh its benefits and limitations. While it offers durability, understanding its performance in real-world scenarios can lead to better project outcomes. The exploration of nonwoven fabric should focus on adapting its use to fit unique project requirements. This reflection can inspire creativity and innovation in projects, unlocking new potential for filtration applications.

This bar chart illustrates the durability scores of various nonwoven filter fabrics. Each fabric is rated on a scale of 1 to 100, reflecting its performance in applications requiring filtration. Polypropylene stands out with the highest durability score, making it an excellent choice for projects demanding long-lasting materials.

Nonwoven filter fabric has become a preferred choice in various industries. Its durability is one of its most significant advantages. According to a market report, the global nonwoven fabric market is expected to reach $50 billion by 2027. This showcases the growing recognition of nonwoven materials. Their robust construction allows for effective filtration, making them essential for applications in water treatment and air filtration.

The ability to resist wear and tear is critical. Nonwoven filter fabrics can withstand harsh environmental conditions. The filtration efficiency of these fabrics is impressively high, often exceeding 90% in various applications. This reliability leads to reduced maintenance costs over time. However, improper installation or handling can lead to performance issues. Ensuring the right choice for specific needs is crucial.

Additionally, these fabrics are lightweight yet strong. This balance allows for ease of installation in various projects. However, the benefits come with a caveat. Selecting the wrong type can result in inefficiencies. Industries should evaluate their specific requirements carefully to avoid costly mistakes. Nonwoven filter fabrics represent a smart investment, but attention to detail is essential for maximizing their potential.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Resistant to wear and tear, suitable for long-term use. | Water filtration, air purification. |

| Chemical Resistance | Withstands exposure to various chemicals without degrading. | Industrial liquid filtration. |

| Lightweight | Easy to handle and install, reducing labor costs. | HVAC systems, portable filtration units. |

| Cost-Effective | Offers long-term savings due to lower replacement frequency. | Residential and commercial filtration projects. |

| Eco-Friendly | Made from recyclable materials and promotes sustainability. | Agricultural filtering, environmental projects. |

Nonwoven filter fabric is increasingly used across various industries. In the manufacturing sector, it plays a vital role in air and water filtration systems. This material is lightweight yet incredibly strong, making it an ideal choice for applications where durability is essential.

In agriculture, nonwoven filter fabric aids in soil erosion control and weed prevention. It allows water and nutrients to pass through while keeping unwanted debris at bay. This use improves crop yields and can lead to better resource management. However, some might argue about its environmental impact, emphasizing the need for more sustainable options.

In the automotive industry, nonwoven filter fabric is essential for cabin air filters and oil filtration. The fabric's structure traps harmful particles, ensuring cleaner air inside the vehicle. While effective, the challenge remains in finding recyclable or biodegradable options. Addressing these concerns can enhance the future utility of nonwoven filter fabrics in a more eco-friendly manner.

When selecting nonwoven filter fabric, several factors come into play. Consider the type of project you are undertaking. Does it require heavy filtration or is it meant for lighter applications? Understanding your specific needs is crucial. The material's weight and thickness also matter. Thicker fabrics often provide better filtration but may restrict flow rate.

Tips: Always assess the environment where the fabric will be used. Is it exposed to harsh chemicals or extreme temperatures? Ensure the selected fabric can withstand those conditions. Quality and durability are essential for long-term projects.

Another important factor is the fabric's pore size. Smaller pores can trap more particles but may lead to clogging. Conversely, larger pores might allow certain particles to pass through. Experimenting with different pore sizes can yield insights into performance. Keep in mind that sometimes, the more you test, the more questions arise.

Ultimately, balance the need for filtration efficiency with operational costs. Quality should not always come at a high price. Reflect on your choices regularly. Is your fabric performing as expected? Adjust your selections based on real-world observations.

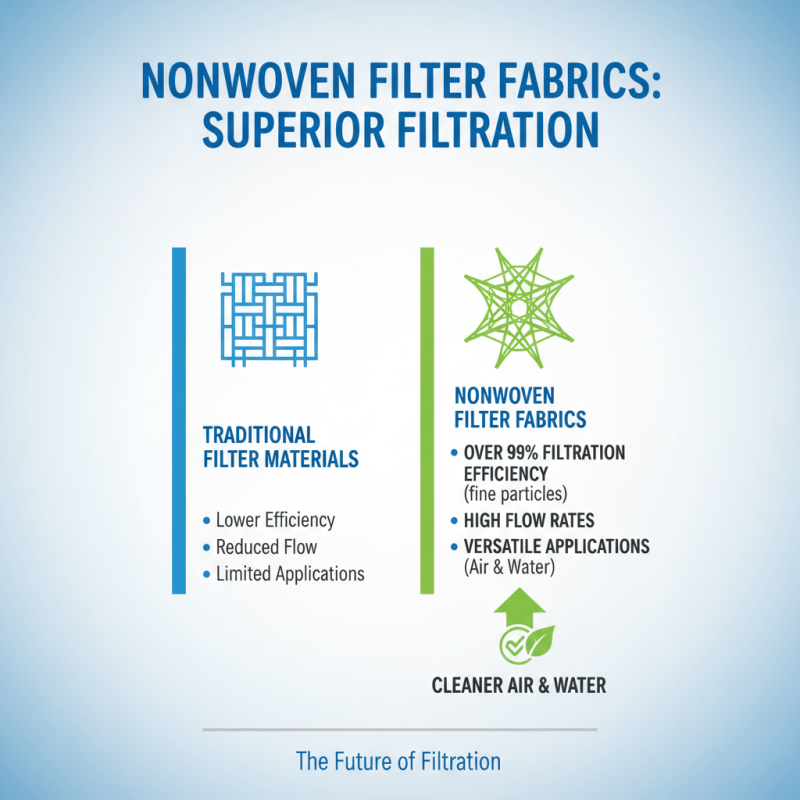

Nonwoven filter fabrics stand out when compared to traditional filter materials. They offer superior filtration efficiency while maintaining high flow rates. Studies show that nonwoven fabrics can achieve efficiencies of over 99% in capturing fine particles. This makes them ideal for various applications, from air filtration to wastewater treatment.

In contrast, woven fabrics typically exhibit pore structures that can clog easily. This can lead to reduced efficiency and increased maintenance costs. The durability of nonwoven fabrics enhances their lifespan. Data from industry reports indicates that nonwoven materials can last up to three times longer than their woven counterparts in similar conditions. This significant difference highlights the effectiveness of choosing nonwoven options for long-term projects.

However, not all nonwoven fabrics are created equal. The manufacturing process and materials used can impact performance. It’s essential to consider factors like fiber composition and bonding methods. Some nonwoven options may not perform as expected in specific conditions. Understanding these nuances can lead to better project outcomes. It's important to select the right type of nonwoven fabric to avoid unexpected challenges.