Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

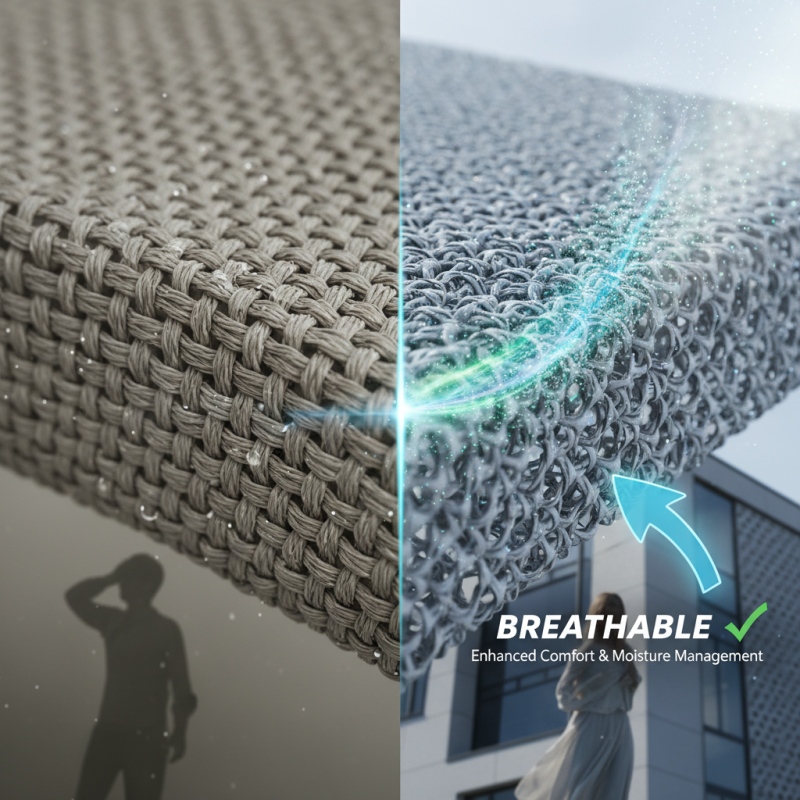

In the ever-evolving world of material science, the significance of "Breathable Material Nonwoven" cannot be overstated. As industries strive for innovation while ensuring comfort and functionality, the adoption of breathable nonwoven materials is rapidly gaining traction. Dr. Emily Carter, a renowned expert in textile technology, emphasizes this trend by stating, "Choosing breathable materials not only enhances user experience but also contributes to sustainability—a vital consideration for modern projects." Her insights shed light on the dual benefits of incorporating nonwoven materials that allow air permeability while also being eco-friendly.

The versatility of breathable nonwoven fabrics extends across multiple industries, from apparel and healthcare to automotive and construction. These materials offer an ideal solution for applications that require moisture management and ventilation, making them crucial for projects aimed at improving the usability and comfort of final products. As we delve deeper into the realm of breathable material nonwoven, it's essential to understand not just their practical advantages but also the technological advancements driving their development.

Furthermore, the ever-increasing demand for sustainable practices in production highlights the importance of selecting breathable nonwoven materials for future projects. As companies move towards eco-conscious solutions, the integration of these innovative fabrics can significantly reduce environmental impact while enhancing product performance. By prioritizing breathable material nonwoven in their designs, businesses can position themselves at the forefront of an industry increasingly focused on quality, comfort, and sustainability.

Breathable nonwoven materials have become increasingly popular in a wide range of applications due to their unique properties and advantages. One of the primary benefits is their ability to allow air and moisture vapor to pass through while providing barrier protection. This feature makes them ideal for use in medical applications, such as surgical drapes and masks, where hygiene and comfort are essential. The lightweight nature of nonwoven fabrics ensures that users can maintain efficiency without compromising safety.

Additionally, breathable nonwoven materials are highly versatile, making them suitable for various industries, including agriculture, construction, and consumer goods. In agriculture, these materials can be used for crop covers, allowing for optimal temperature and moisture control while preventing harmful pests. In construction, nonwoven fabrics can serve as effective barrier layers in roofing and insulation, helping to regulate airflow and enhance energy efficiency. Their adaptability and breathability not only improve functionality but also contribute to sustainability, as many nonwoven materials are biodegradable and can reduce environmental impact.

Nonwoven materials have gained popularity in various projects due to their breathable and functional characteristics. One of the key features that makes nonwoven fabric breathable is its unique structure. Unlike traditional woven fabrics, nonwoven materials are made by binding fibers together through mechanical, thermal, or chemical processes. This results in a fabric with numerous microscopic openings, allowing air to circulate freely while still providing adequate protection and support. This property not only enhances comfort but also makes these materials suitable for a wide range of applications, from medical products to industrial uses.

When selecting nonwoven materials, consider the weight and density of the fabric. Lighter nonwoven materials are generally more breathable, making them suitable for clothing and products that require ventilation. Moreover, think about the end use of your project. Nonwoven fabrics can be engineered to have specific attributes, such as water resistance or antimicrobial properties, which can further enhance their functionality.

Tips: Always conduct a test with the selected nonwoven material to ensure it meets your project’s desired comfort and durability levels. Additionally, consider layering nonwoven fabrics to maximize performance—this can provide a balance of breathability and protection tailored to your needs. By focusing on these aspects, you can fully leverage the advantages of breathable nonwoven materials in your next project.

Breathable nonwoven fabrics offer an innovative solution for various projects while making a positive environmental impact. Unlike traditional materials, which often rely on complex weaving processes, nonwoven fabrics are made by bonding fibers together, resulting in lightweight, versatile options that allow air and moisture to pass through. This breathability is vital for applications ranging from medical supplies to outdoor apparel, providing comfort without compromising performance.

Choosing breathable nonwoven materials contributes to sustainability efforts, as many of these fabrics are designed for recyclability or made from recycled content. Their production processes often require less energy and water compared to conventional fabrics, leading to reduced carbon footprints. Furthermore, with increased awareness of environmental issues, projects utilizing eco-friendly materials can resonate better with consumers, promoting green practices without sacrificing quality or effectiveness.

Tips for selecting breathable nonwoven fabrics include assessing the specific needs of your project regarding durability, permeability, and intended use. Researching various types of nonwoven materials can ensure you choose the right option that balances functionality and ecological responsibility. Additionally, consider collaborating with suppliers who prioritize sustainable practices, as this can amplify the positive impact of your project on the environment.

| Material Type | Breathability (G/M²/24H) | Environmental Impact (CO₂ kg/m²) | Biodegradability (%) | Typical Applications |

|---|---|---|---|---|

| Polypropylene Nonwoven | 300 | 0.85 | 0% | Medical, Hygiene Products |

| Cotton Nonwoven | 180 | 0.40 | 90% | Fashion, Disposable Items |

| Bamboo Nonwoven | 250 | 0.35 | 100% | Home Textiles, Baby Products |

| Recycled PET Nonwoven | 220 | 0.60 | 0% | Packaging, Insulation |

| PLA Nonwoven | 150 | 0.50 | 100% | Agricultural, Medical |

In recent years, the construction and textile industries have seen a surge in the adoption of breathable nonwoven materials, particularly in applications requiring moisture management and enhanced comfort. A comparative analysis reveals that breathable nonwovens offer significant advantages over traditional materials like woven fabrics and plastics. For instance, according to a report by Technavio, the global nonwoven fabric market is projected to grow by USD 16.08 billion between 2020 and 2024, largely attributed to their superior breathability and lightweight nature. Traditional materials often retain moisture, leading to discomfort in applications like apparel and medical textiles, whereas nonwovens allow for effective air and moisture flow, promoting skin health and overall well-being.

When considering materials for your next project, here are a few tips: First, evaluate the breathability specifications of the nonwoven fabric based on your specific needs. Look for industry standards that measure airflow and moisture vapor transmission rates. Second, consider the environmental impact—many nonwoven materials are produced from recycled content and can also be designed for biodegradability, aligning with sustainability goals. Lastly, engage in testing and prototyping to assess how these materials perform in real-world conditions, ensuring they meet the project’s requirements effectively.

Ultimately, the choice of breathable nonwoven fabrics over traditional materials can lead to improved performance and user satisfaction across various applications, making them a wise investment for modern projects in numerous industries.

When selecting breathable nonwoven materials for your next project, it’s essential to consider several key factors to ensure optimal performance and suitability. Breathable nonwovens often play a critical role in applications ranging from medical products to environmental barriers and apparel. The right material can enhance comfort, improve functionality, and extend the life of your project.

One vital tip is to evaluate the fabric's permeability and moisture-wicking properties. Look for materials that allow air and moisture to escape while preventing external elements from intruding. This dual functionality is particularly important in applications where breathability impacts user comfort and safety, such as in personal protective equipment or activewear.

Additionally, consider the weight and thickness of the nonwoven material. Lighter fabrics typically enhance breathability, whereas thicker ones may offer more durability but at the expense of airflow. Strike a balance based on your project needs; for instance, if your application demands higher durability without sacrificing breathability, look for spunbond or meltblown nonwovens that combine both characteristics effectively. Paying attention to these details will lead you to the perfect nonwoven material for your project.