Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

Choosing the right material for your projects is crucial, especially when it comes to functionality and aesthetics. Lamination Nonwoven Fabric has gained significant popularity due to its versatility and durability, making it an excellent choice for a wide range of applications. Whether you're working on fashion items, home decor, or functional products, understanding the qualities that define the best Lamination Nonwoven Fabric can greatly enhance the outcome of your work.

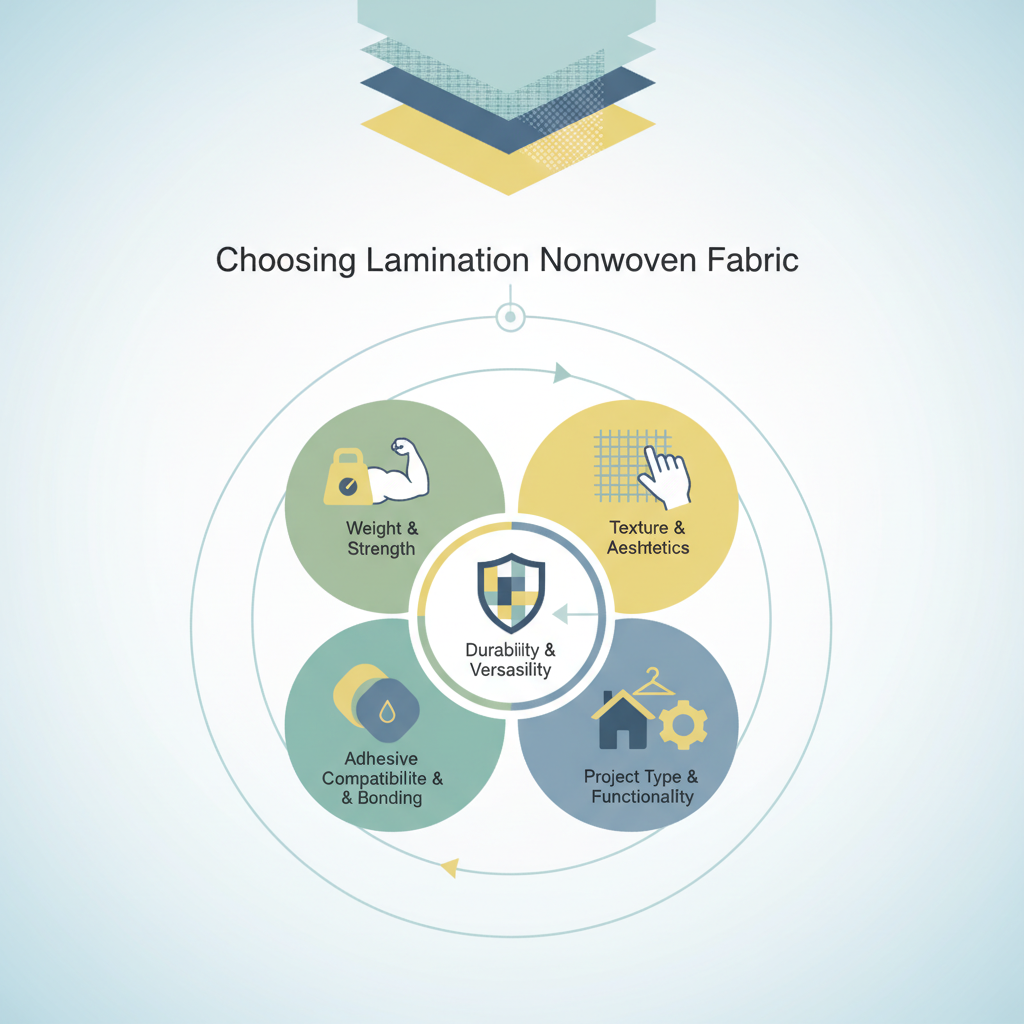

When selecting Lamination Nonwoven Fabric, it's essential to consider various factors, such as the fabric's weight, strength, and texture, which can impact its performance in different settings. Additionally, compatibility with adhesives and other materials is vital to ensure a successful lamination process. The purpose of this article is to guide you through the decision-making process to help you identify the most suitable Lamination Nonwoven Fabric for your specific needs, ensuring both functionality and visual appeal in your projects.

Nonwoven fabrics are versatile materials that have found applications across various industries due to their unique properties. Unlike woven fabrics, nonwovens are produced by binding fibers together through mechanical, thermal, or chemical processes. This results in a fabric that is lightweight, strong, and often more cost-effective than traditional textiles. Common uses include disposable products like surgical gowns and masks, insulation in automotive applications, and even landscaping materials. As a result of their adaptability, nonwoven fabrics are increasingly favored in sectors that prioritize sustainability and efficiency.

The demand for nonwoven fabrics is projected to grow significantly in the coming years, driven by advancements in manufacturing technologies and an increasing emphasis on environmentally friendly materials. For instance, innovations utilizing bio-based and recycled materials are reshaping the landscape, making nonwovens not only practical but also more sustainable. This transition is particularly evident in industries such as automotive and healthcare, where the need for lightweight, efficient, and eco-friendly alternatives is becoming a priority. Understanding these factors can help stakeholders choose the best lamination nonwoven fabric suited for their specific projects, ensuring quality and performance while addressing environmental concerns.

When selecting the best lamination nonwoven fabric for your projects, it is essential to understand the key characteristics that differentiate these materials. One of the primary features to consider is the weight of the fabric, which influences its durability and application range. Lighter nonwoven fabrics are ideal for disposable items, while heavier variants provide greater strength and are suited for products that require longevity and stability.

Additionally, the type of fibers used in the lamination process significantly impacts the fabric’s performance. Synthetic fibers like polypropylene or polyester offer excellent moisture resistance and UV protection, making them perfect for outdoor applications. On the other hand, natural fibers can provide breathability and softness, which are desirable in products intended for direct skin contact. Lastly, the bonding method used in lamination affects the fabric’s texture and flexibility, with options ranging from needle-punched to thermal-laminated finishes, each providing distinct advantages tailored to different project requirements.

| Characteristic | Description | Applications |

|---|---|---|

| Durability | Resistant to tearing, fraying, and environmental factors. | Medical gowns, industrial covers, and upholstery. |

| Weight | Available in various weights to suit different needs. | Fashion items, bags, and insulation materials. |

| Moisture Resistance | Assess the ability to repel water and moisture. | Outdoor applications, disposable medical supplies. |

| Ease of Printing | Compatibility with various printing methods. | Promotional products and custom bags. |

| Eco-Friendliness | Utilization of recyclable or biodegradable materials. | Sustainable fashion and packaging solutions. |

When selecting the right lamination nonwoven fabric for your projects, several key criteria should be considered to ensure optimal performance and durability.

First and foremost, the fabric's weight and thickness play a crucial role. According to a recent report by Smithers Pira, the nonwoven fabric market is projected to reach $50 billion by 2025, with heavier and thicker materials gaining popularity for their superior resistance to wear and tear.

This characteristic is particularly important in applications like automotive interiors and medical textiles, where the fabric's longevity directly impacts the product's lifecycle.

Another significant factor is the type of polymer used in the lamination process. Different polymers can impart various properties to the fabric, such as moisture resistance or breathability.

Research from the Nonwoven Institute indicates that polyester and polypropylene are among the most commonly used polymers due to their balance of strength and lightweight characteristics.

Evaluating these materials in conjunction with the intended application's specific needs will ensure the chosen fabric meets all performance expectations.

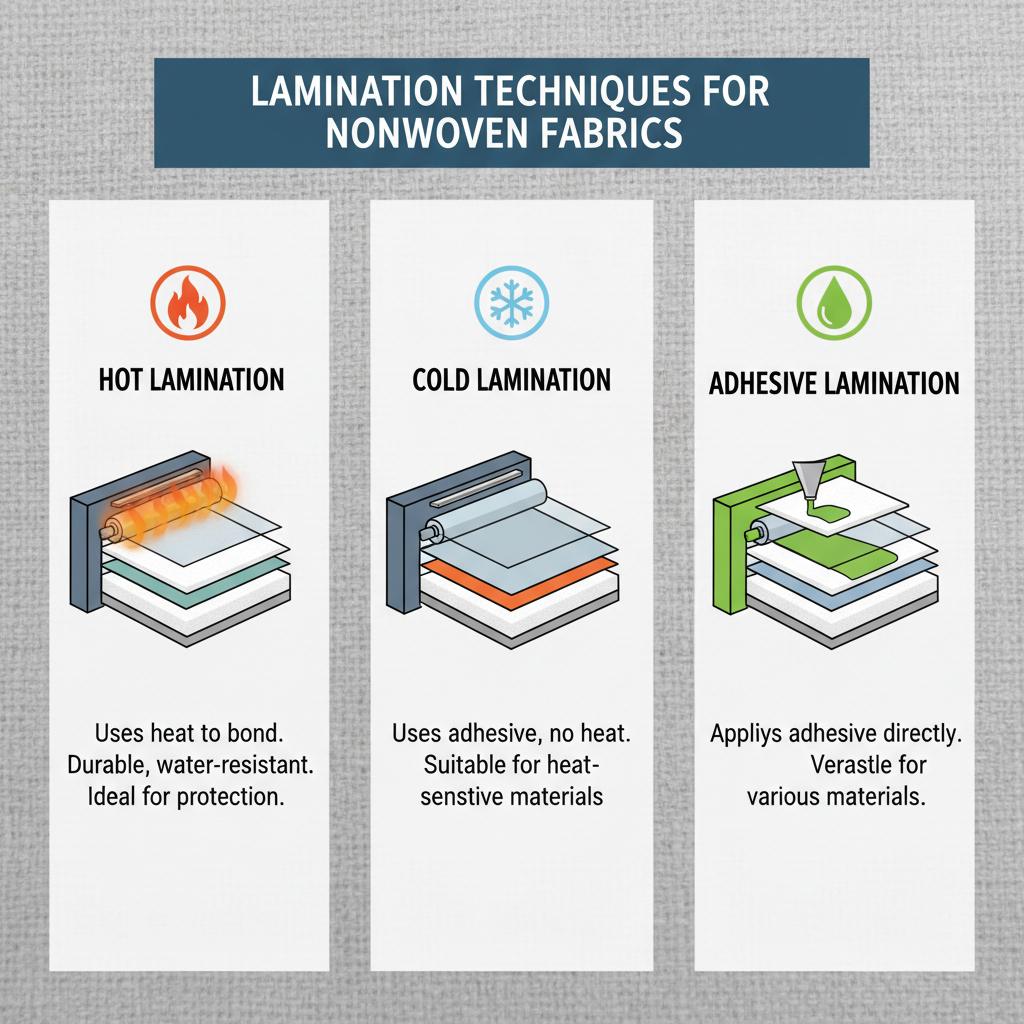

When selecting the best lamination nonwoven fabric for your projects, it’s essential to understand the various lamination techniques available. There are several methods such as hot lamination, cold lamination, and adhesive lamination, each with distinct advantages depending on your specific requirements. Hot lamination uses heat to bond layers together, providing a durable and water-resistant finish, ideal for products that require extra protection. Cold lamination, on the other hand, utilizes adhesive without heat, making it suitable for heat-sensitive materials.

Tips: When choosing a lamination technique, consider the end use of the fabric; for high durability and outdoor applications, hot lamination may be the best choice. For projects that prioritize flexibility and ease of use, cold lamination might be more appropriate. Additionally, exploring new advancements in materials like engineered wood products and laminated carbon electrodes can enhance sustainability and efficiency in your projects.

Another aspect worth considering is the environmental impact of your chosen lamination method. Techniques that focus on minimizing waste and utilizing sustainable materials can not only improve the longevity of your products but also align with eco-friendly practices. Remember, every decision in the lamination process plays a crucial role in the overall quality and sustainability of your final project.

When selecting the best lamination nonwoven fabric for your projects, it's essential to consider several key factors to maximize its benefits. First, evaluate the specific requirements of your project, such as durability, texture, and resistance to wear and tear. Different nonwoven fabrics come with varying properties, making it critical to choose one that aligns with the intended use. For example, if you're working on products that will experience a lot of friction or exposure to the elements, opt for a fabric designed to withstand such conditions.

Next, look at the application techniques you plan to use with the fabric. Whether you’re considering heat lamination or adhesive bonding, ensure that the nonwoven fabric is compatible with your chosen lamination method. Additionally, keep in mind the environmental impact of your choices. Selecting nonwoven fabrics made from sustainable materials can enhance your project by appealing to eco-conscious consumers. By paying attention to these details, you can ensure that you not only choose the right fabric but also leverage its properties to achieve optimal results in your work.

This chart illustrates the popularity of different types of lamination nonwoven fabrics based on their applications. The data highlights the percentage usage of each fabric type in various project categories.