Leave Your Message

-

CONTACT WhatsApp

CONTACT WhatsApp -

-

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT EMAIL

CONTACT EMAIL

In the ever-evolving landscape of healthcare, the demand for high-quality materials to ensure patient safety and comfort has never been more critical. Nonwoven for medical fabric has emerged as a pivotal component in the production of protective garments, surgical drapes, and various medical supplies. According to a report by Smithers Pira, the global market for nonwoven fabrics is projected to reach over $50 billion by 2024, fueled by the growing need in the medical sector alongside other applications. The unique properties of nonwoven fabrics, such as their lightweight nature, breathability, and barrier protection capability, make them ideal for medical uses.

Choosing the right nonwoven fabric for medical applications can significantly impact outcomes in infection control and patient care. The versatility of nonwoven materials allows for a wide range of applications, from single-use surgical gowns to wound care products. Furthermore, industry statistics indicate that nearly 40% of nonwoven fabrics produced worldwide are utilized in healthcare settings. This underscores the need for healthcare professionals and manufacturers to stay informed about the latest innovations and standards in nonwoven fabrics to ensure optimal product performance and safety for users. As we explore the best nonwoven fabrics for medical use, it is essential to consider factors such as material composition, filtration efficiency, and regulatory compliance to make informed choices tailored to specific medical needs.

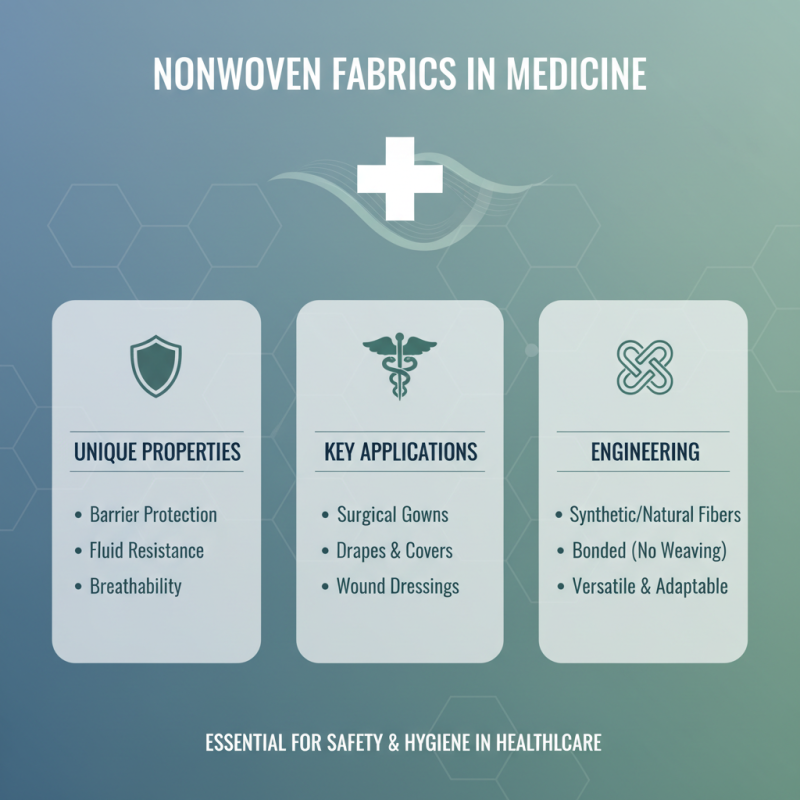

Nonwoven fabrics have become essential components in the medical field due to their unique properties and versatility. These materials are engineered from synthetic or natural fibers that are bonded together through various physical or chemical processes, eliminating the need for traditional weaving. In medical applications, nonwoven fabrics are utilized for a variety of purposes, including surgical gowns, masks, drapes, and wound dressings. Their ability to provide barrier protection, fluid resistance, and breathability makes them optimal for ensuring both patient and healthcare provider safety.

When selecting the right nonwoven fabric for medical use, it is crucial to consider the specific requirements of the application. Factors such as absorbency, tensile strength, flexibility, and biocompatibility play significant roles in determining performance. Additionally, fabrics should meet stringent healthcare regulations regarding sterilization and microbial resistance. The choice of fiber composition, thickness, and layer construction can significantly impact the fabric's effectiveness and suitability for different medical environments, from sterile surgeries to everyday preventive measures in clinics and hospitals.

When selecting nonwoven fabrics for medical use, it's essential to understand the different types that are available and their respective applications. Nonwoven fabrics can be broadly categorized into spunbond, meltblown, and needlepunch types. Spunbond nonwovens, characterized by their durability and strength, are commonly utilized in surgical gowns and drapes. According to a 2022 report by Smithers Pira, the global market for spunbond nonwovens in medical applications is projected to grow at a rate of 6.5% annually through 2027, driven by increasing demand for disposable medical products.

Meltblown nonwovens, on the other hand, are renowned for their excellent filtration properties, making them ideal for face masks and respirators. The versatility of meltblown fabric allows for its use in various infection control applications, which has become increasingly vital in healthcare settings. A study published in the Journal of Applied Polymer Science indicates that meltblown fabrics can achieve filtration efficiencies exceeding 90%, highlighting their importance in protecting healthcare workers and patients alike.

Lastly, needlepunch nonwoven fabrics, while not as commonly used in high-risk medical environments, provide good resilience and comfort, making them suitable for bedding and soft medical products. The choice of nonwoven fabric ultimately depends on the intended use and the specific requirements of the healthcare facility. Understanding these types of nonwoven fabrics ensures that healthcare providers can select the right materials to enhance safety and performance in medical settings.

When selecting nonwoven fabrics for medical applications, it is essential to consider several key characteristics that impact functionality and performance. One of the primary factors is the fabric’s barrier properties, which determine its effectiveness in preventing the penetration of liquids and pathogens. According to a report from the Nonwovens Institute, medical-grade nonwoven fabrics should ideally have a hydrostatic head pressure of at least 10 cm to ensure adequate protection during procedures.

Another critical characteristic is breathability. Nonwoven fabrics must allow air and moisture vapor to escape, reducing the risk of heat and moisture buildup, which can lead to discomfort or skin irritation for patients. Research published by the American Association of Textile Chemists and Colorists emphasizes that the ideal air permeability for medical nonwovens ranges between 50 to 300 L/m²/s, striking a balance between protection and comfort.

Durability is also paramount; the fabric should withstand handling and procedures without compromising integrity. The tensile strength and tear resistance are crucial metrics, often evaluated using standardized ASTM tests. Fabrics that meet or exceed the minimum industry standards, which typically require a tensile strength of at least 4 N, will provide the necessary reliability in demanding medical environments. By focusing on these characteristics—barrier properties, breathability, and durability—healthcare professionals can select the most suitable nonwoven fabrics for their specific needs.

| Fabric Type | Key Characteristics | Applications | Benefits |

|---|---|---|---|

| Spunbond Polypropylene | Lightweight, breathable, and water-resistant | Surgical gowns, drapes | Cost-effective, good barrier properties |

| SMS (Spunbond-Meltblown-Spunbond) | High filtration, fluid resistance | Face masks, isolation gowns | Excellent protection, soft feel |

| Meltblown Polypropylene | Fine fiber structure, high liquid repellency | Surgical masks, filtration materials | Effective for filtration, comfortable |

| Polyethylene (PE) | Waterproof, durable | Covers, aprons | Reusable and economical |

| Viscose | Soft, biodegradable | Wound dressings, surgical sponges | Gentle on skin, eco-friendly |

Nonwoven fabrics play a crucial role in healthcare settings, where they are employed in various applications due to their unique properties. These materials are engineered to provide excellent barrier protection against contaminants, making them ideal for use in surgical gowns, drapes, and masks. Their ability to resist fluid penetration while maintaining breathability allows medical professionals to perform their duties safely and effectively. Furthermore, nonwoven fabrics are often designed for single-use applications, which helps minimize the risk of cross-contamination in clinical environments.

In addition to personal protective equipment, nonwoven fabrics are extensively used in wound care and hygiene products. They are employed in dressings, bandages, and absorbent pads, offering exceptional moisture retention and comfort for patients. The lightweight nature of nonwoven materials also facilitates their use in disposable undergarments and bed linens, providing hygienic solutions for patient care. As the healthcare industry continues to prioritize infection control, the versatility and effectiveness of nonwoven fabrics make them a vital component in ensuring safety and efficacy in medical environments.

In the medical field, the choice of nonwoven fabrics is crucial as they serve a variety of functions from isolation gowns to surgical drapes. A comparative analysis of popular nonwoven fabric brands reveals significant variations in their composition, performance, and suitability for specific applications. According to a report by Smithers Pira, the global market for nonwoven fabrics is expected to reach approximately $53 billion by 2025, indicating a growing recognition of their importance in healthcare settings.

Key characteristics to consider when evaluating nonwoven fabrics include fluid resistance, bacterial filtration efficiency (BFE), and particle filtration efficiency (PFE). Industry standards often highlight that fabrics with a BFE of over 98% are ideal for surgical masks, whereas those with PFE of 95% or higher are preferred for superior barrier protection. Additionally, some nonwoven materials are engineered with antimicrobial agents to reduce the risk of infection, enhancing their suitability for use in sterile environments.

As healthcare demands evolve, the shift towards sustainable, biodegradable nonwoven options is also gaining traction, aligning with global sustainability goals while maintaining the performance standards required in medical applications.